Intelligent drilling rod for petroleum and natural gas extraction and manufacture method thereof

A natural gas and drill pipe technology, which is applied in the direction of drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of inability to transmit electricity, out-of-synchronization of data transmission, etc., to avoid corrosion failure, the production method is simple and easy, and the work efficiency is high Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

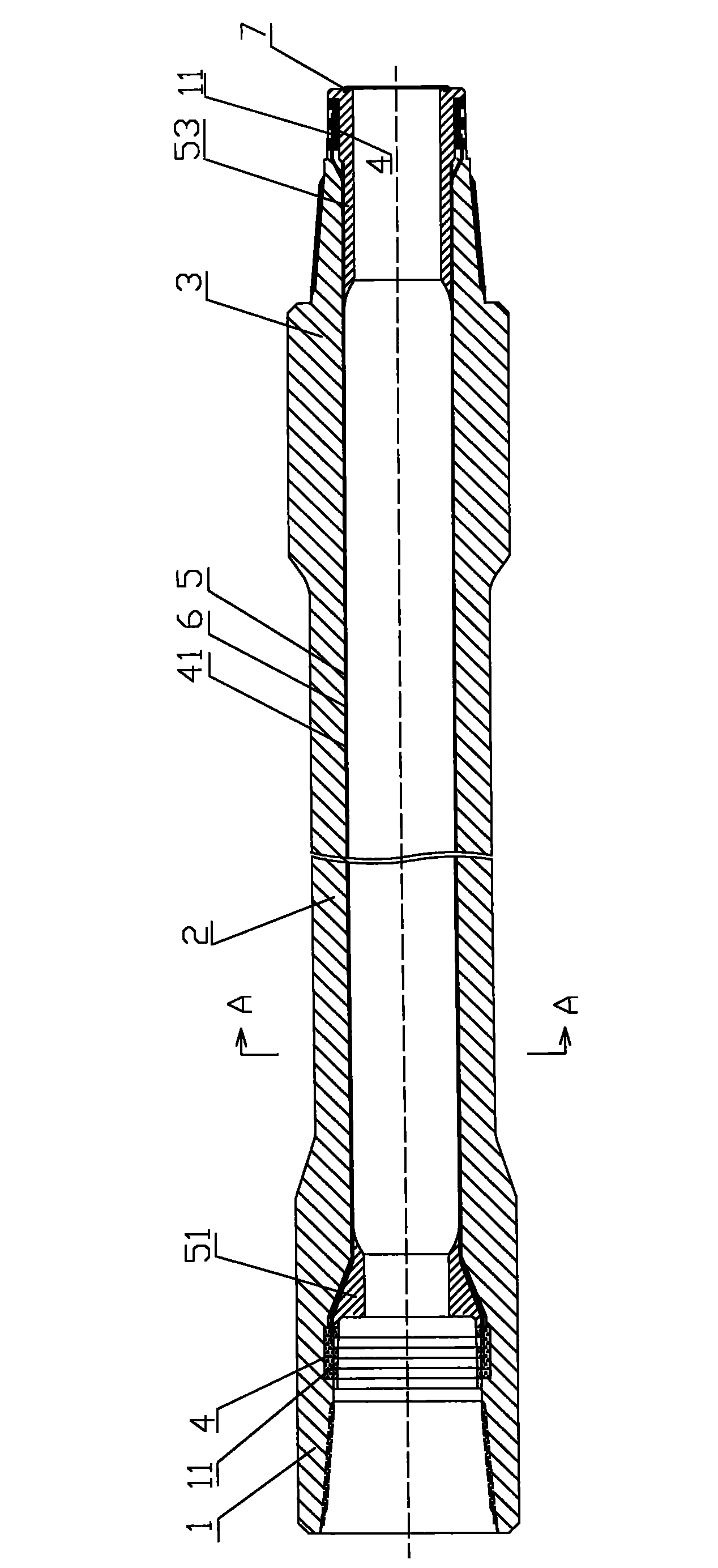

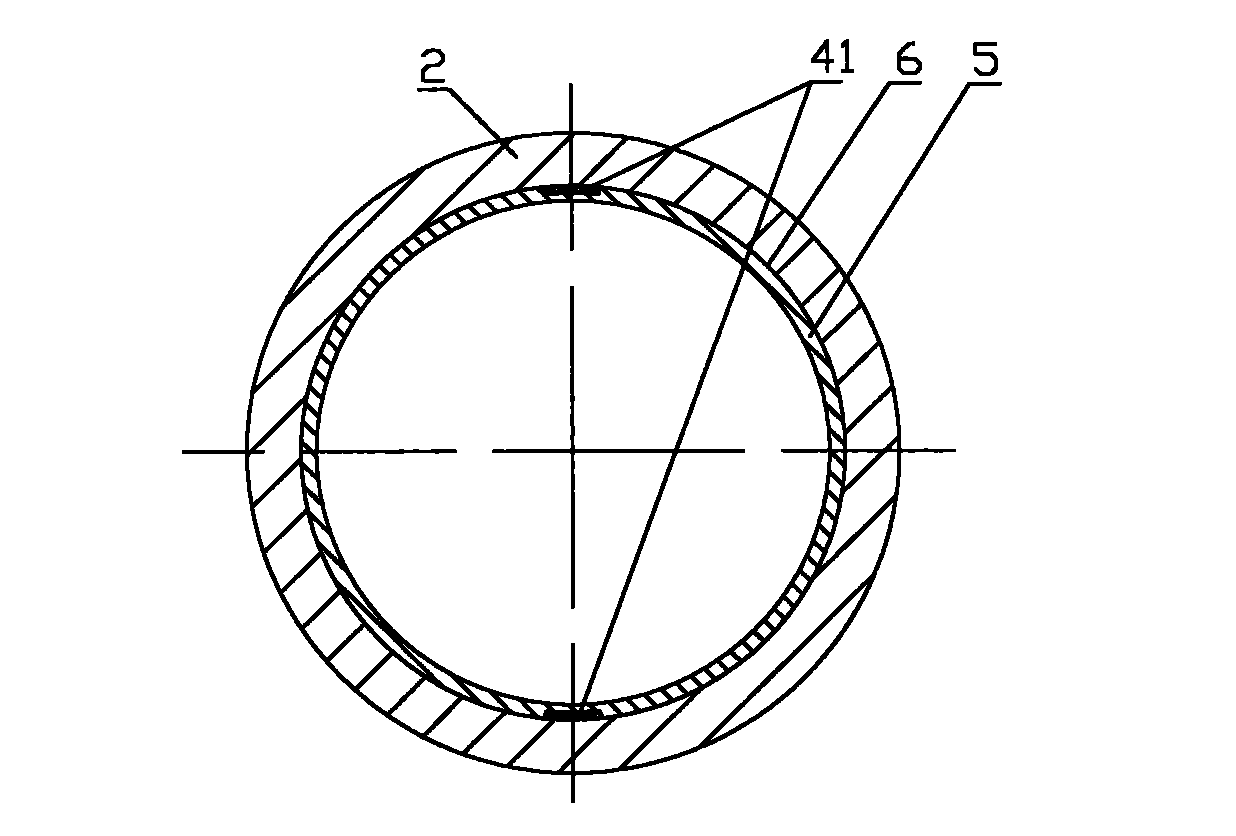

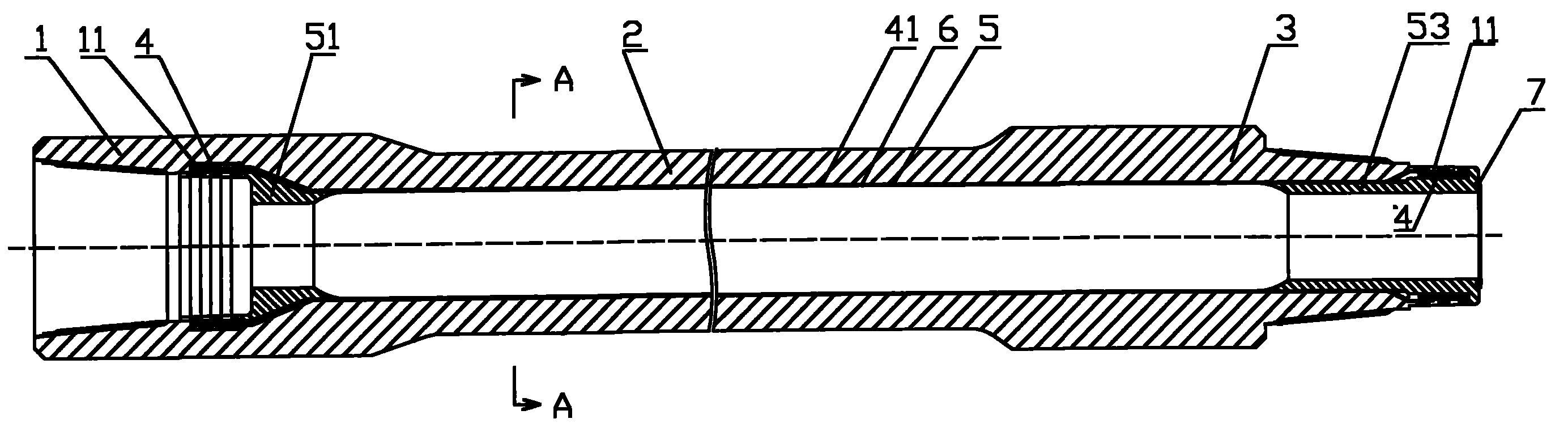

[0023] like figure 1 and figure 2 As shown, the intelligent drill pipe used for oil and natural gas exploitation of the present invention includes a drill pipe body 2, an internally threaded joint 1 and an externally threaded joint 3 arranged at both ends of the drill pipe body 2, an internal cavity and an externally threaded joint 1 located at the internally threaded joint 1 The conductive ring positioning protection sleeve 4 and the conductive ring 11 of the extended section of the joint 3; it also includes the inner liner 5 of the pipe, the inner threaded joint bushing 51, the inner threaded joint lining positioning sleeve 53, the high temperature resistant sealing ring 7 and several cables 41 , the outer wall of the lining pipe 5 in the pipe body is provided with several grooves in the axial direction, and the several cables 41 are laid in the several grooves of the liner pipe 5 in the pipe body through the high temperature resistant metal adhesive 6. The liner 5 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com