Powdery mixture containing phytosterol and oryzanol and preparation method thereof

A technology of phytosterols and mixtures, which is applied in the direction of medical preparations containing active ingredients, food preparation, drug combinations, etc., can solve the problem of limited solubility or dispersibility, cannot significantly improve bioavailability, and poor solubility of phytosterol powder To achieve the effect of improving bioavailability, lowering the level of total cholesterol in the human body, and lowering the level of total serum cholesterol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

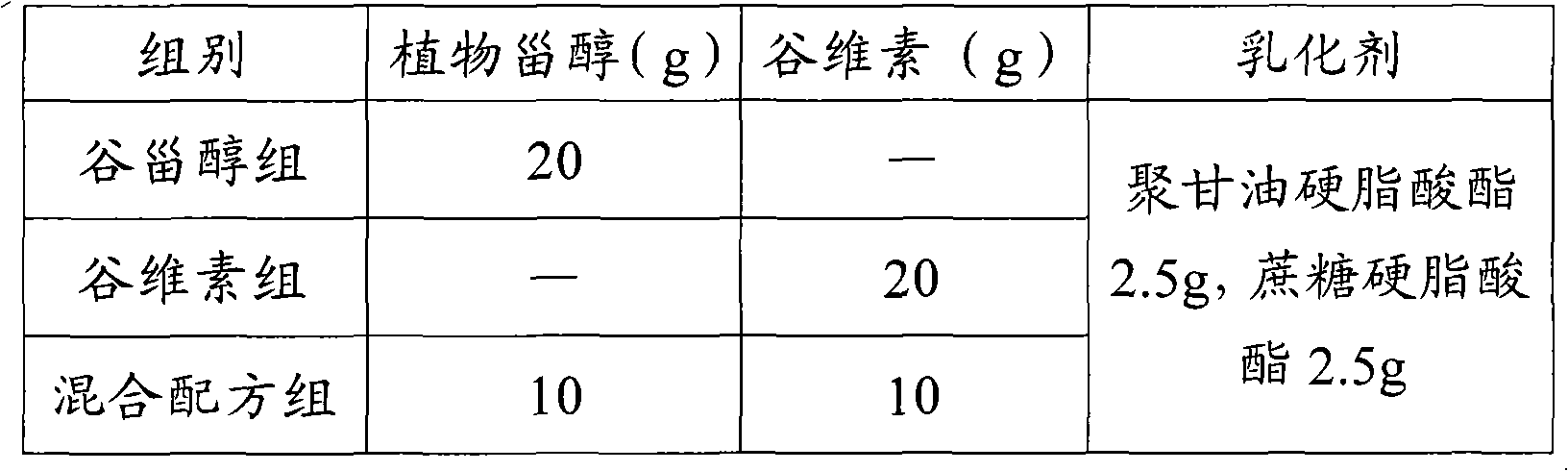

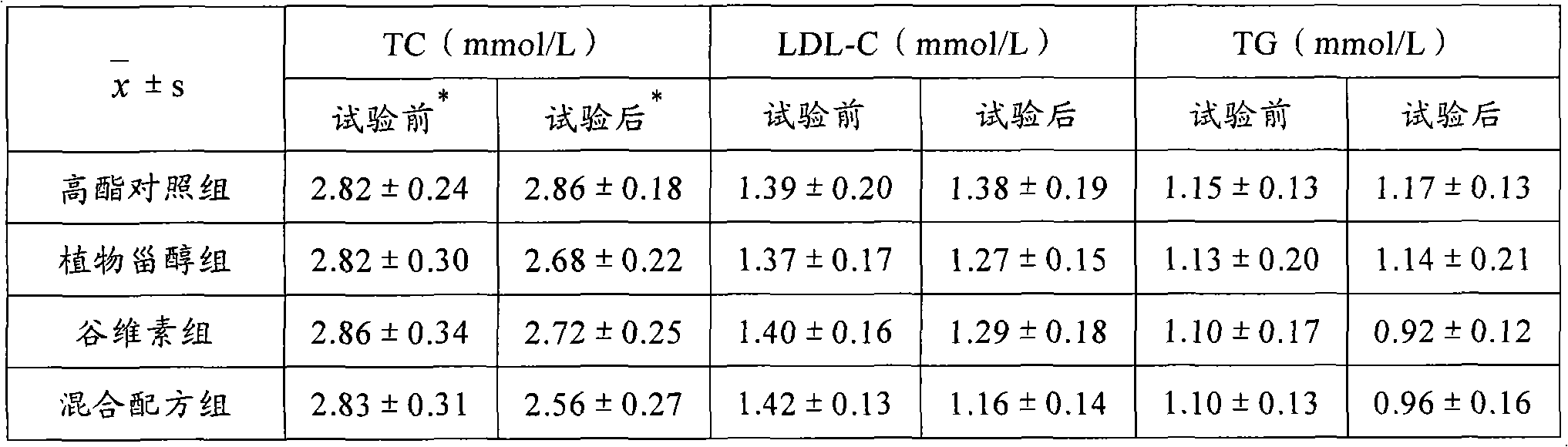

[0022] In a 200 mL container, 10 g of sitosterol, 10 g of oryzanol, and 5 g of polyglyceryl stearate (HLB12) were mixed, and then the mixture was melted at 140° C. under stirring. After complete melting, the mixture was stored at -10°C for rapid cooling. After the obtained solid was preliminarily crushed, it was further crushed with a ball mill (the grinding medium was zirconia beads). After grinding, the grinding medium was sieved to remove the grinding medium. After pulverization, the sample was sampled for measurement. The diameter of the powder was less than 100 μm. The data are shown in Table 1.

[0023] Table 1

[0024] Particle size (μm)

[0025] 18.86

Embodiment 2

[0027] In a 200 mL container, 10 g of campesterol, 10 g of oryzanol, and 5 g of sucrose stearate (HLB13) were mixed, and then the mixture was melted at 140° C. under stirring. After complete melting, the mixture was stored at -10°C for rapid cooling. After the obtained solid was preliminarily pulverized, it was further pulverized with a ball mill (the grinding medium was zirconia beads), and after grinding, it was sieved to remove the grinding medium. After pulverization, the sample was sampled and measured. The diameter of the powder was less than 100 μm, and the data was similar to that of Example 1.

Embodiment 3

[0029] In a 200 mL container, 15 g of sitosterol, 5 g of oryzanol, 2.5 g of polyglyceryl stearate (HLB12) and 2.5 g of sucrose stearate (HLB 13) were mixed, and then the mixture was melted at 140° C. under stirring. After complete melting, the mixture was stored at -10°C for rapid cooling. The obtained solid was preliminarily pulverized and then pulverized by a jet mill. The diameter of the pulverized sample powder was less than 20 μm. The data are shown in Table 2.

[0030] Table 2

[0031] Particle size (μm)

[0032] 3.519

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com