Embedded nano iron/microbe microspheres and preparation method thereof

A technology of microbial microspheres and nano-iron, applied in the nano field, can solve the problems of insignificant synergy between nano-iron and microorganisms, difficult popularization and application of pollutants, low effective contact rate of nano-iron, etc., and achieves good biocompatibility, The effect of easy separation and small average particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

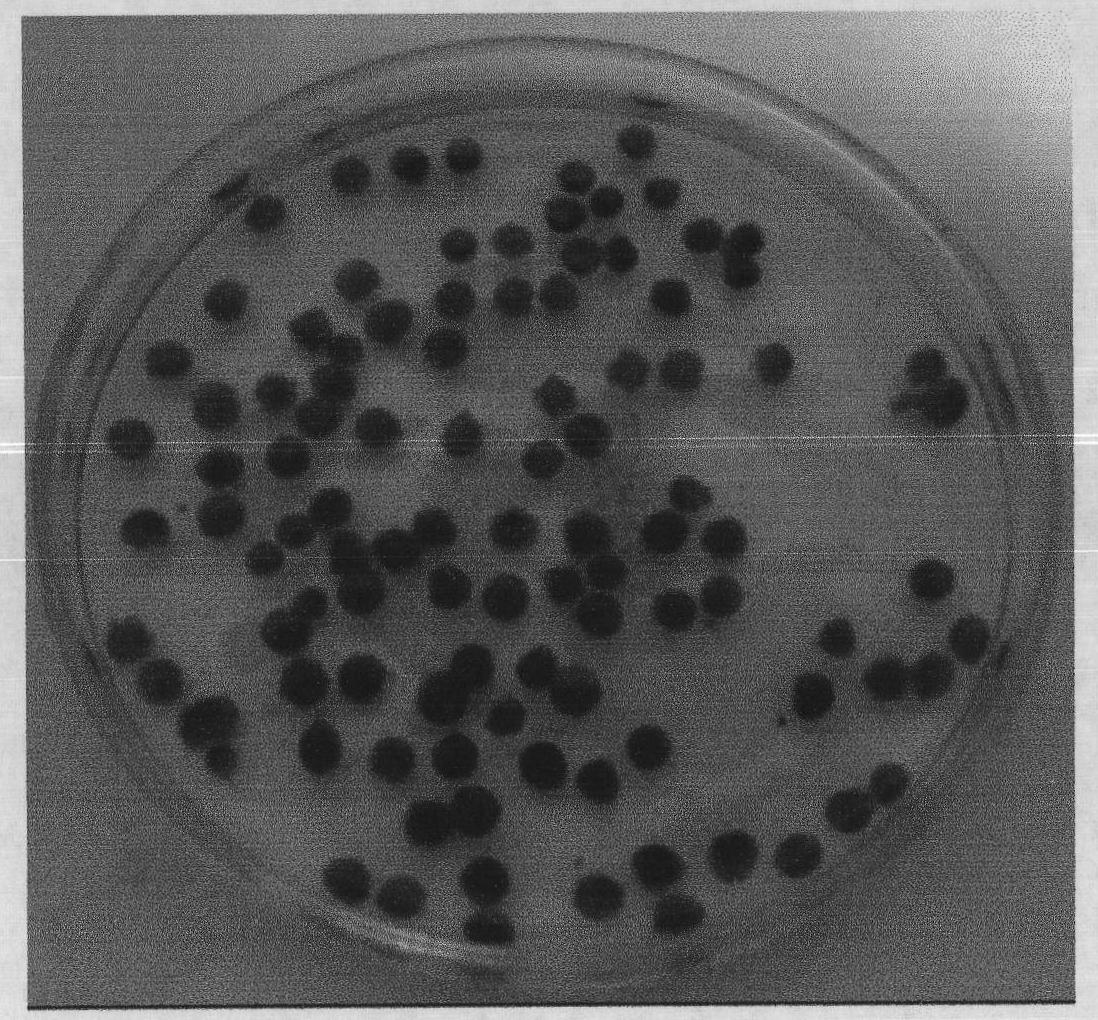

Image

Examples

Embodiment 1

[0033] (1) Preparation of embedding agent sodium alginate solution

[0034] Dissolving sodium alginate particles in water and heating to a transparent state to obtain a sodium alginate solution with a mass percent content of 2%;

[0035] (2) Preparation of crosslinking agent calcium chloride solution

[0036] Calcium chloride powder is dissolved in water to obtain a calcium chloride solution with a molar concentration of 0.2mol / L;

[0037] (3) Preparation of nano-iron solution

[0038] Using liquid phase reduction method, strong reducing agent KBH 4 Reduced FeSO 4 ·7H 2 O gets Fe 0 , with Fe 0 Prepare a nano-iron solution with a molar concentration of 0.1g / L;

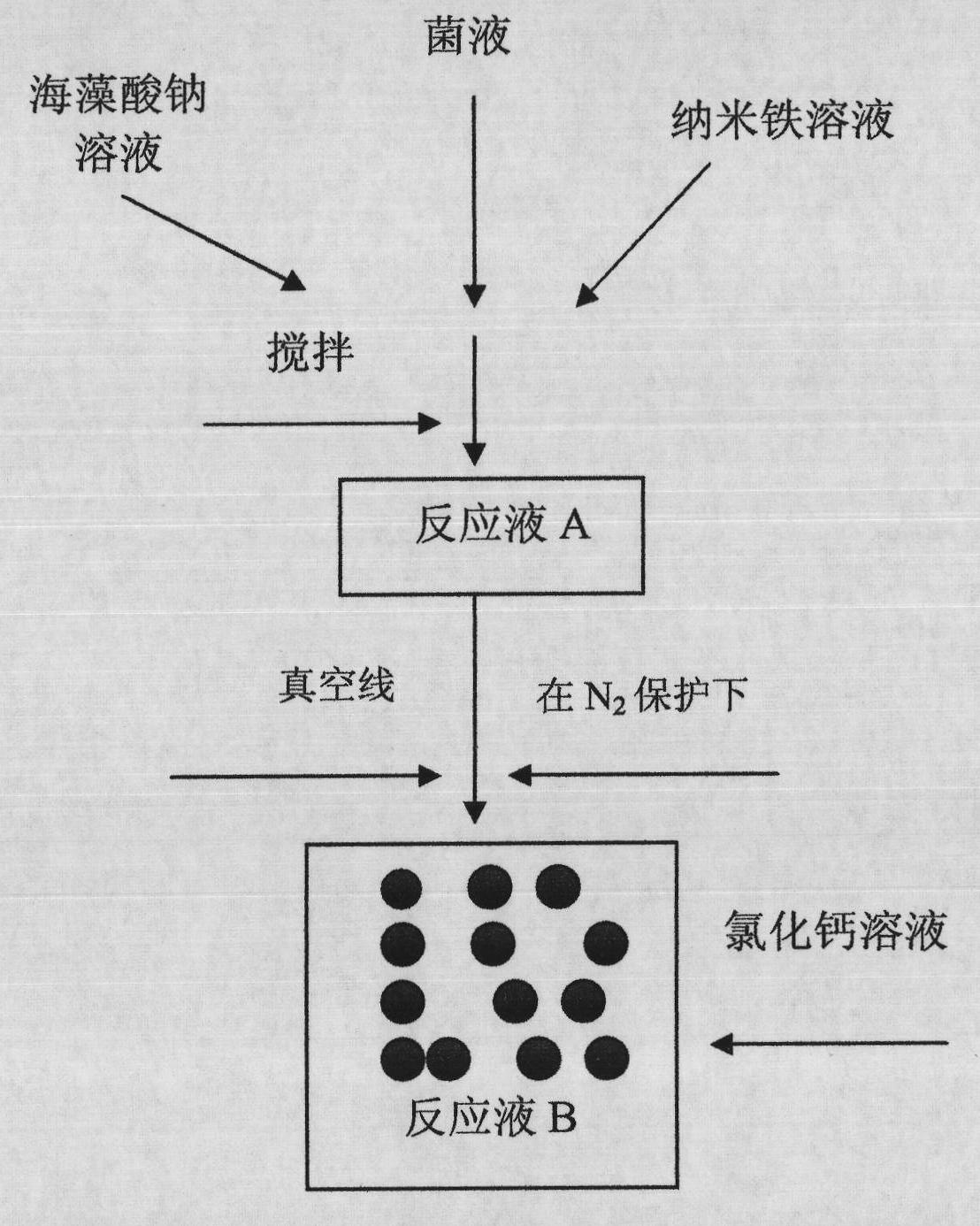

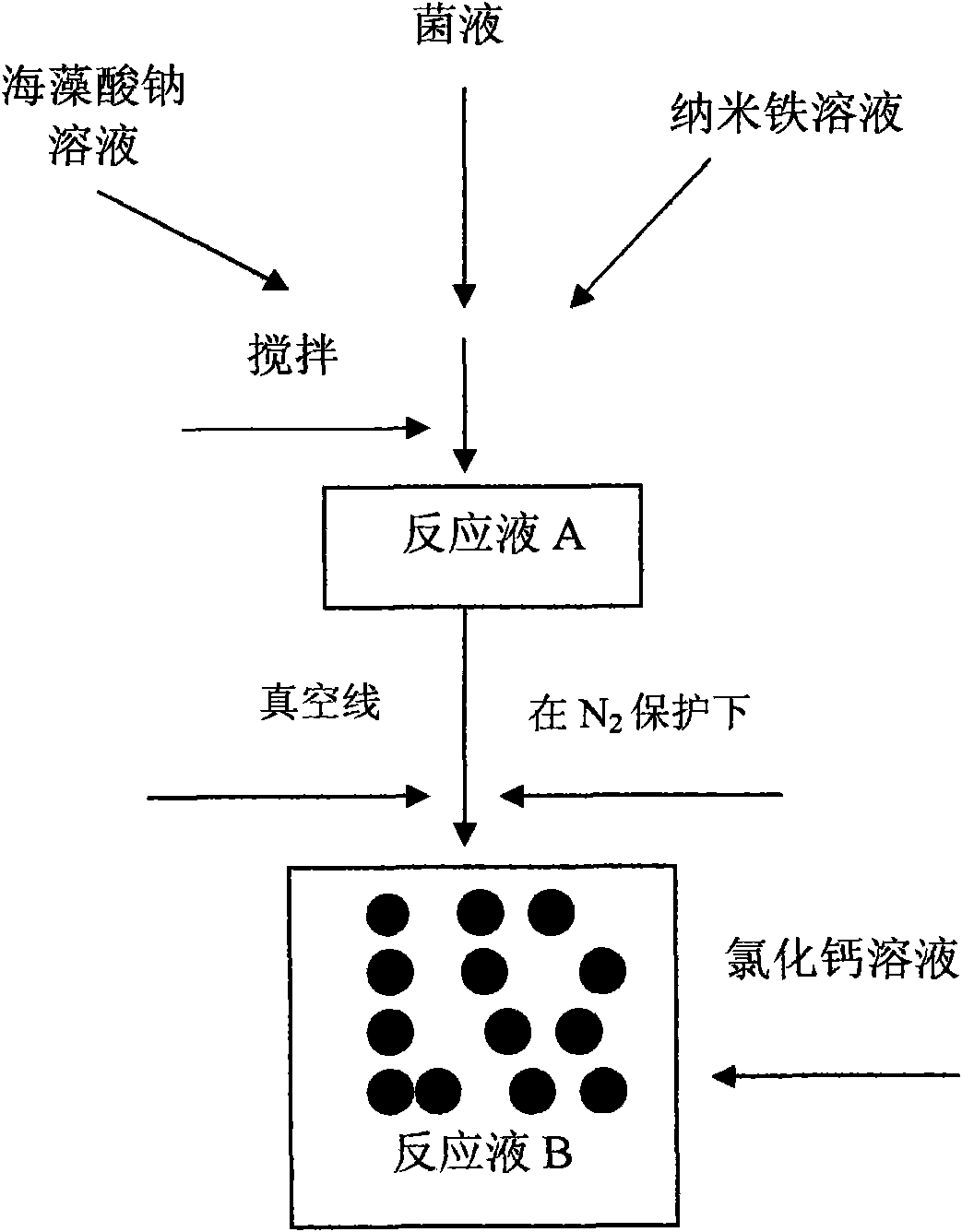

[0039] (4) Preparation of reaction solution A

[0040] Add bacterial solution and sodium alginate solution to the nano-iron solution, the volume ratio is 2:3:5, and then mechanically stir for 10 minutes to make the mixing uniform and sufficient to obtain the reaction solution A;

[0041] (5) Preparation of reac...

Embodiment 2

[0047] (1) Preparation of embedding agent sodium alginate solution

[0048] Dissolving sodium alginate particles in water and heating to a transparent state to obtain a sodium alginate solution with a mass percent content of 3.5%;

[0049] (2) Preparation of crosslinking agent calcium chloride solution

[0050] Calcium chloride powder is dissolved in water to obtain a calcium chloride solution with a molar concentration of 0.15mol / L;

[0051] (3) Preparation of nano-iron solution

[0052] Using liquid phase reduction method, strong reducing agent KBH 4 Reduced FeSO 4 ·7H 2 O gets Fe 0 , with Fe 0 Prepare the nano-iron solution whose molar concentration is 0.3g / L;

[0053] (4) Preparation of reaction solution A

[0054] Add bacterial solution and sodium alginate solution to the nano-iron solution, the volume ratio is 2:3:5, and then mechanically stir for 15 minutes to make the mixing uniform and sufficient to obtain the reaction solution A;

[0055] (5) Preparation of ...

Embodiment 3

[0061] (1) Preparation of embedding agent sodium alginate solution

[0062] Dissolving sodium alginate particles in water and heating to a transparent state to obtain a sodium alginate solution with a mass percent content of 1.5%;

[0063] (2) Preparation of crosslinking agent calcium chloride solution

[0064] Calcium chloride powder is dissolved in water to obtain a calcium chloride solution with a molar concentration of 0.3mol / L;

[0065] (3) Preparation of nano-iron solution

[0066] Using liquid phase reduction method, strong reducing agent KBH 4 Reduced FeSO 4 ·7H 2 O gets Fe 0 , with Fe 0 Prepare a nano-iron solution with a molar concentration of 0.1g / L;

[0067] (4) Preparation of reaction solution A

[0068] Add bacterial liquid and sodium alginate solution to the nano-iron solution, the volume ratio is 2:3:5, and then mechanically stir for 8 minutes to make the mixing uniform and sufficient to obtain the reaction solution A;

[0069] (5) Preparation of react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com