Hall element differential array based ferromagnetic construction member surface crack detector

A technology of differential arrays and ferromagnetic components, which is applied in the direction of instruments, measuring devices, and material magnetic variables, can solve the problems of small one-time detection area, hindering the application of magnetic flux leakage method, and inaccurate detection, so as to facilitate analysis and evaluation, Broad market application prospects, the effect of large detection area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

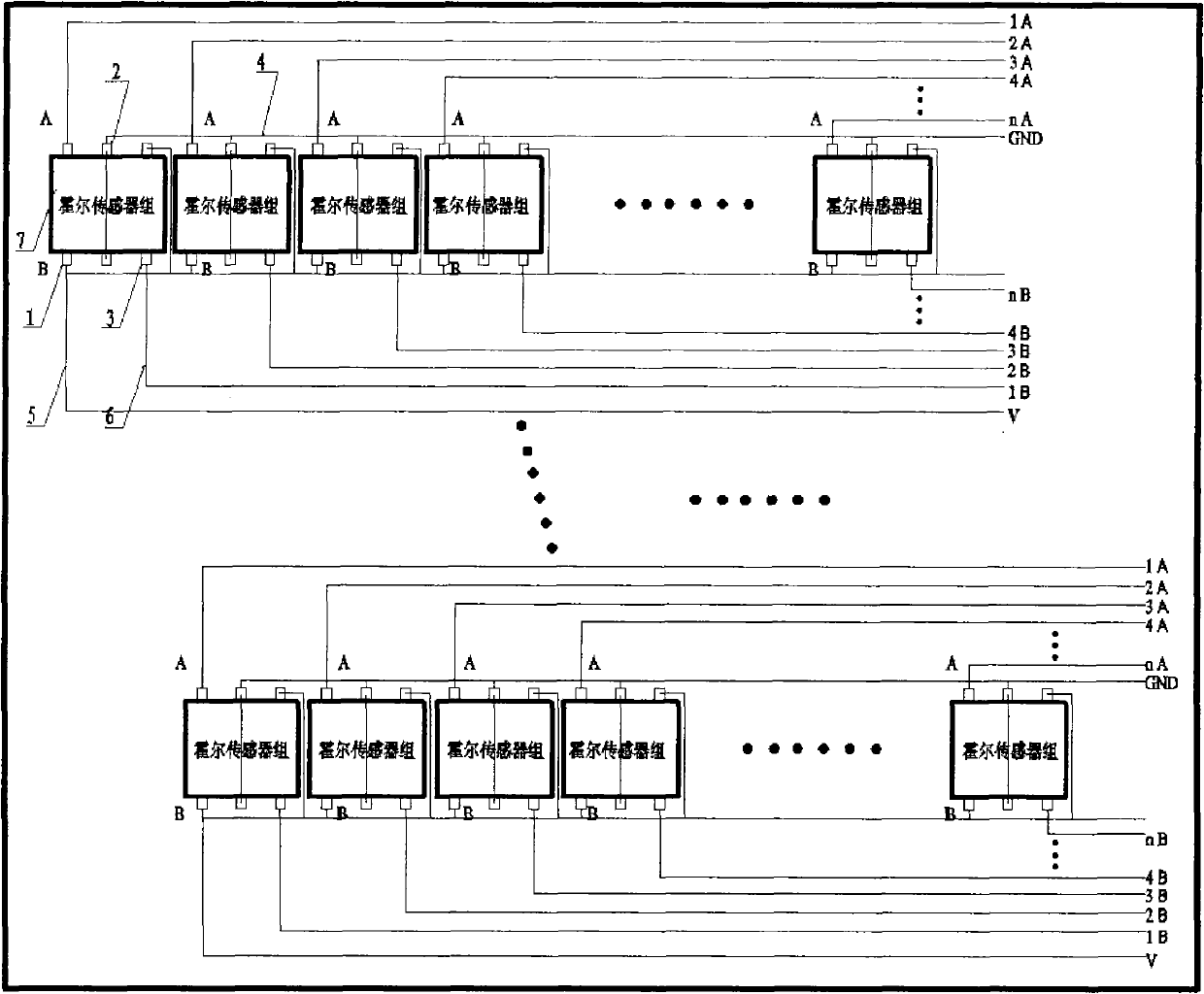

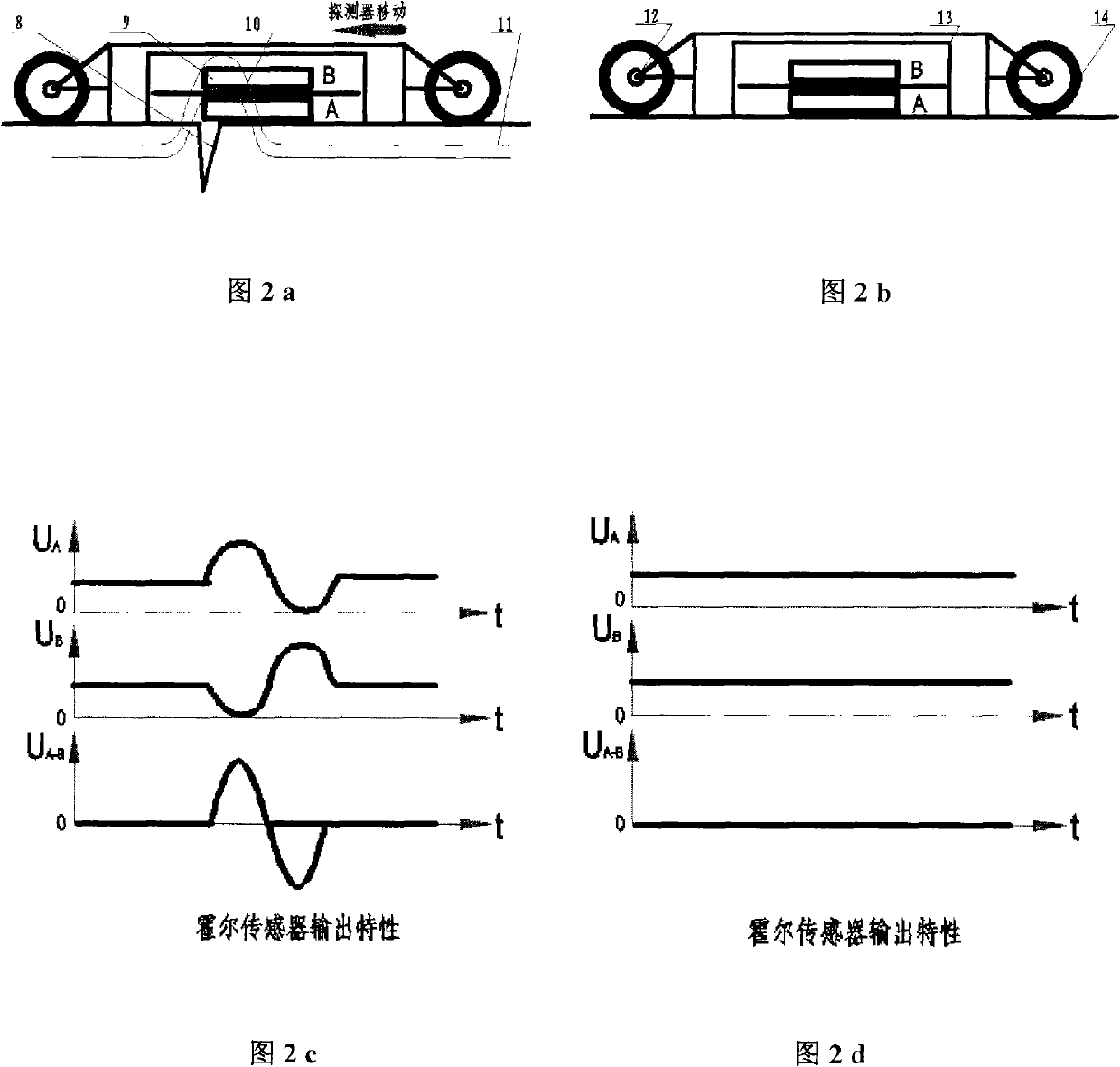

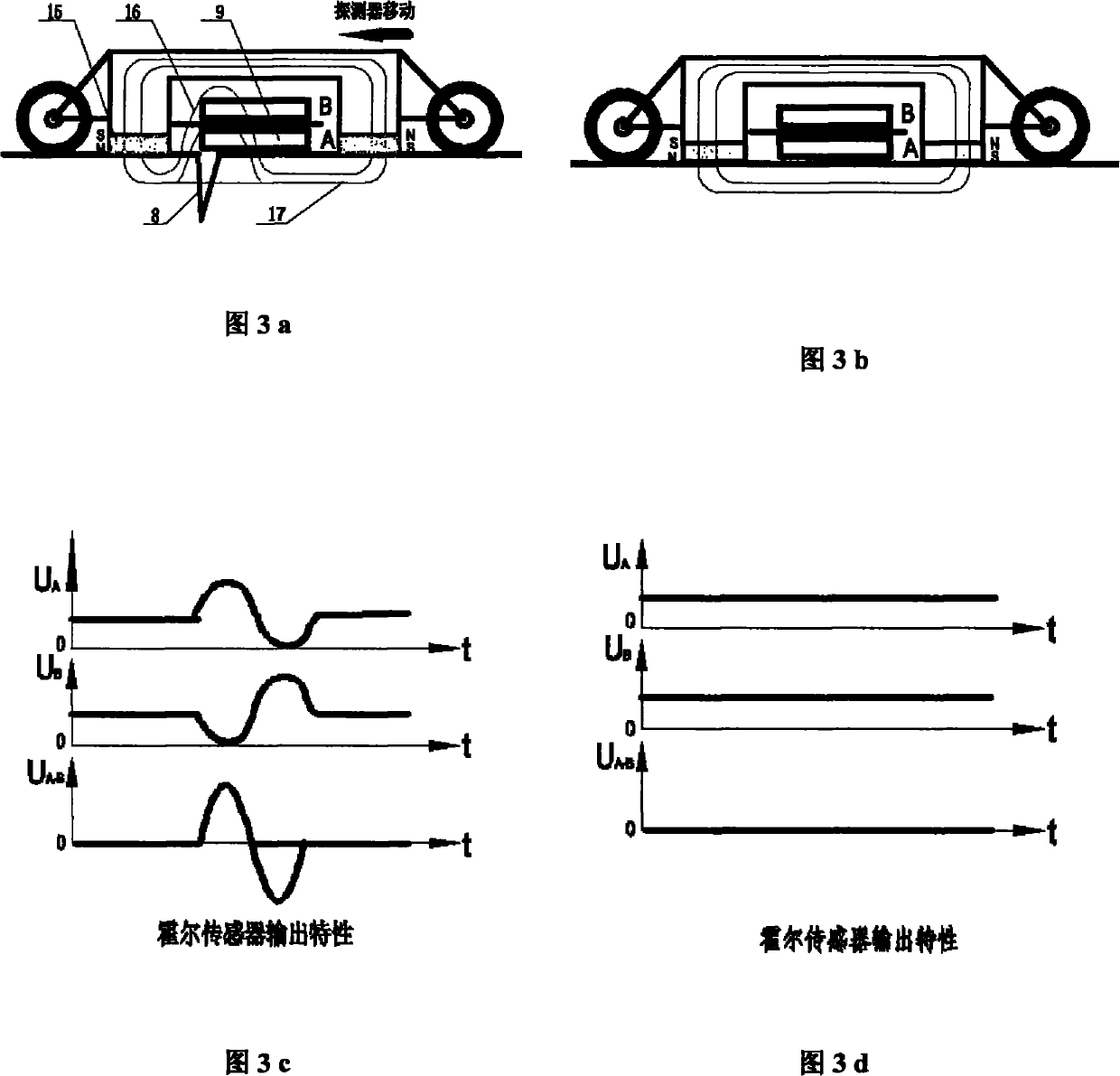

[0027] The structure and working principle of the ferromagnetic component surface crack detector based on the differential array of Hall elements can be found in figure 1 and figure 2 . The surface crack detector of the ferromagnetic component based on the Hall element differential array includes a differential array magnetic flux leakage probe 7, a displacement detection unit 13, a signal conditioning circuit, and a data acquisition unit. The differential array magnetic flux leakage probe 7 includes a circuit board and a plurality of Hall sensor groups 9, and each Hall sensor group 9 is composed of two identical Hall sensor groups that are symmetrically installed on the upper and lower surfaces of the circuit board and reversely arranged. Hall sensors, the installation method can be welding; the Hall sensors located on the same side surface of the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com