The method of changing the right angle of the top of the groove with a larger size into a clearly rounded corner

A grooved, right-angle technology, applied in the field of changing the right angle at the top of a larger-sized groove into an obvious rounded corner, to prevent sealing, expand the scope of application, and reduce difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

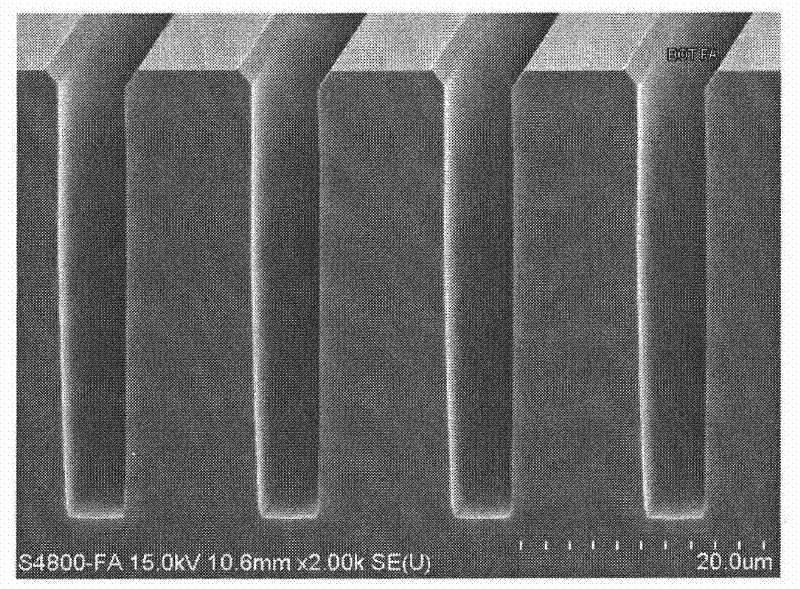

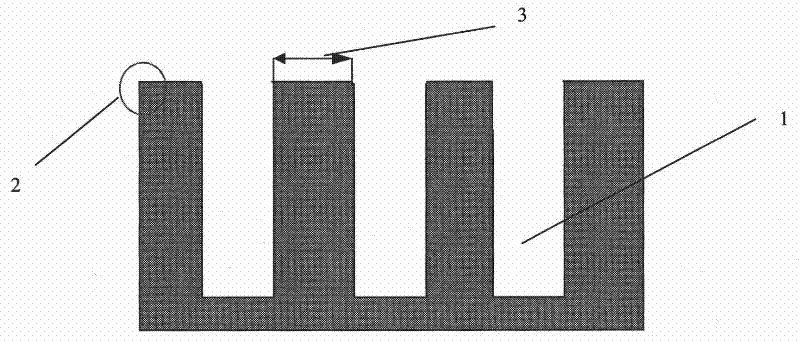

[0025] 1) A series of grooves 1 are etched on the silicon substrate, the width of the groove 1 is 2.0um, the depth of the groove 1 is 10.0um, and the distance 3 between the two grooves is between 0.5um-1.0um, forming Groove top right angle 2 (see figure 2 );

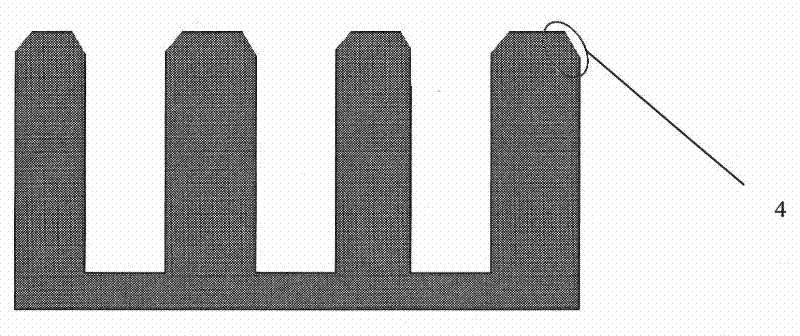

[0026] 2) Use hydrogen chloride gas to etch the right angle 2 on the top of the trench in an atmospheric pressure CVD machine to form an obtuse angle 4 (see image 3 );

[0027] 3) A layer of silicon oxide is grown inside and on the surface of the trench 1 by a thermal oxidation process, with a thickness of 5000 angstroms; and then the silicon oxide is removed with a hydrofluoric acid solution to form a smooth rounded corner 6 at the top of the trench (see Figure 5 ).

Embodiment 2

[0029] 1) A series of grooves 1 are etched on the silicon substrate, the width of the groove 1 is 5.0um, the depth of the groove 1 is 30.0um, and the distance 3 between the two grooves is between 2.0um-10.0um (see figure 2 );

[0030] 2) Use hydrogen chloride gas to etch the right angle 2 on the top of the trench in an atmospheric pressure CVD growth machine to form an obtuse angle 4 (see image 3 );

[0031] 3) Use argon gas to bombard the obtuse angle 4 on the top of the trench in a high-density plasma CVD growth machine to form a relatively rough fillet 5 (see Figure 4 );

[0032] 4) A layer of silicon oxide is grown inside and on the surface of the trench 1 by a thermal oxidation process, with a thickness of 5000 angstroms; and then the silicon oxide is removed with a hydrofluoric acid solution to form a smooth rounded corner 6 at the top of the trench (see Figure 5 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com