Aluminum super-iron alkaline battery

An alkaline battery, high-speed rail technology, applied in alkaline storage batteries, battery electrodes, aqueous electrolyte batteries, etc., can solve the problems that high-speed iron batteries are not mature enough and have not been widely used in production, and achieve the effect of stable discharge and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The aluminum-high-iron alkaline battery of the present invention can be manufactured by using the raw materials and products of the prior art.

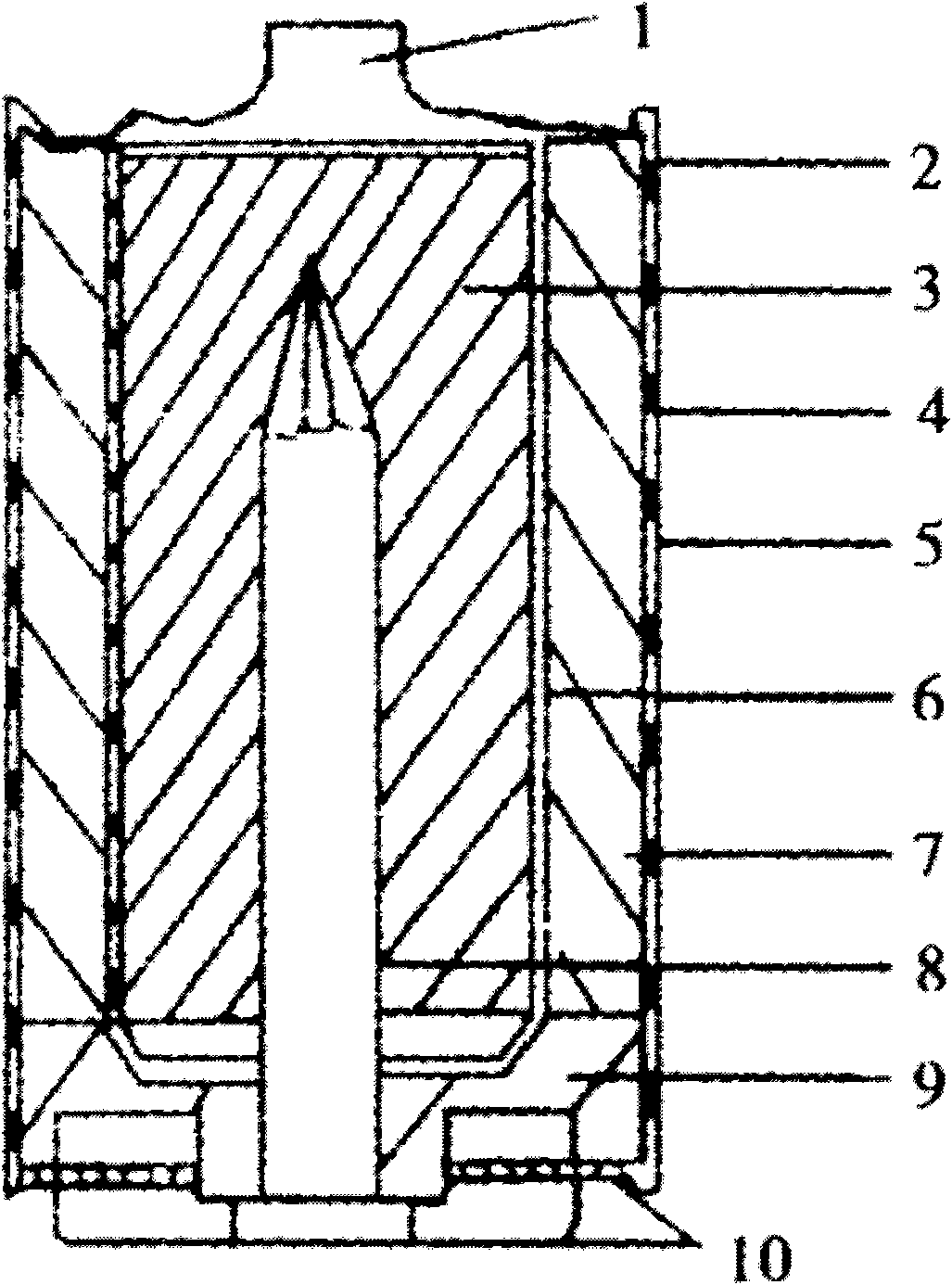

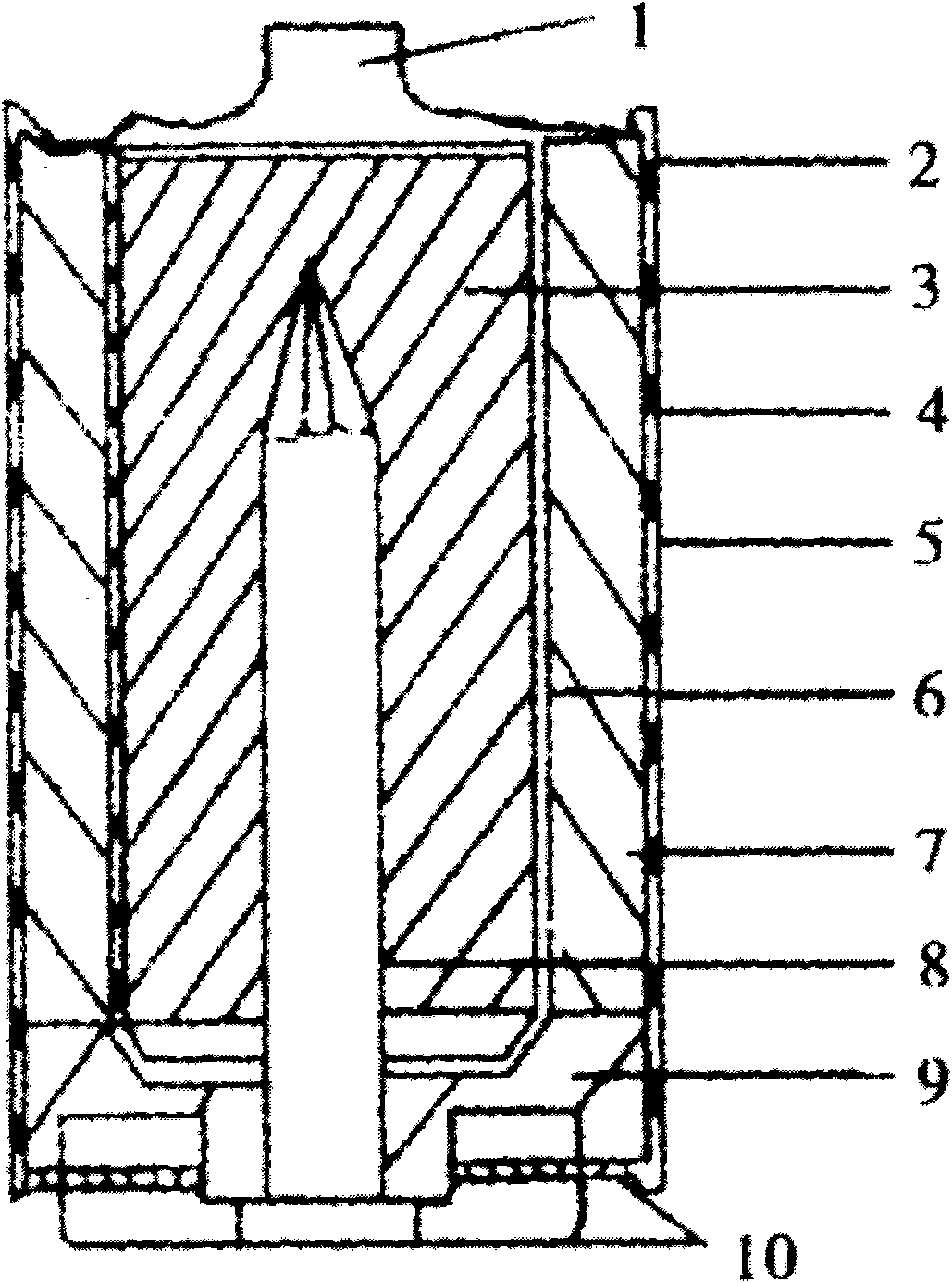

[0017] Aluminum ferric alkaline battery of the present invention, its battery structure is the same as prior art, as figure 1 As shown, it consists of a metal top cap (1), a plastic sleeve (2), a negative electrode (3), a steel shell (4), a metal jacket (5), an isolation layer (6), a positive electrode material ring (7), and a negative electrode set Flow column (8), plastic bottom (9), metal bottom cover insulating washer (10) combination forms.

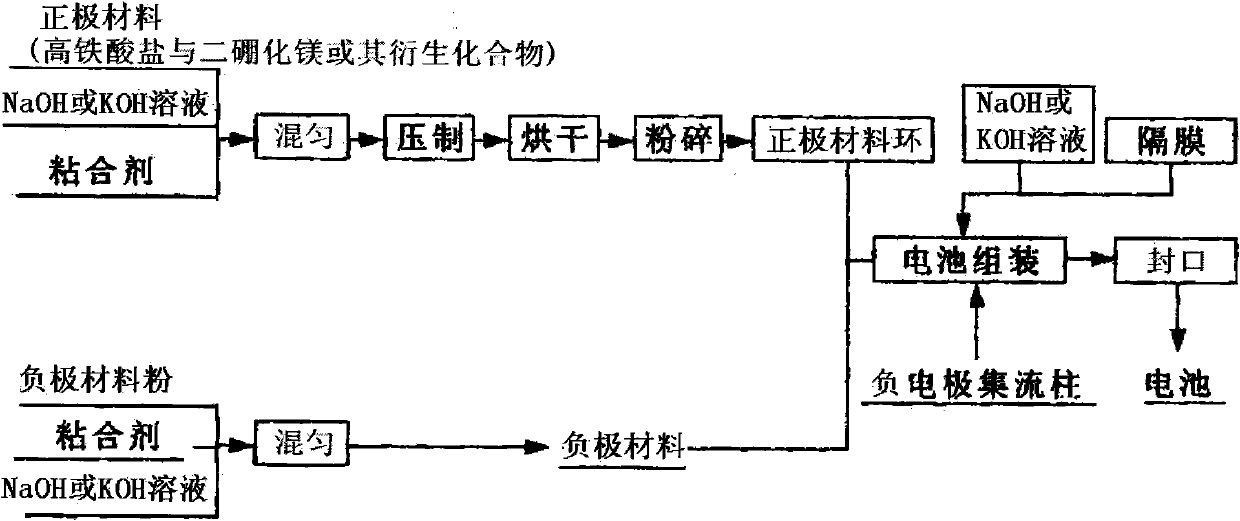

[0018] Aluminum high iron alkaline battery of the present invention, its battery manufacturing process flow is the same as that of the prior art, as figure 2 (process flow chart) shown. details as follows:

[0019] In the process flow, the amount of NaOH or KOH aqueous solution used for mixing positive electrode materials can be carried out according to the general proportion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com