Tooth brush holder and stirring process of raw material thereof

A technology for brush handles and toothbrushes, which is applied in the mixing process of toothbrush handles and their raw materials. It can solve problems such as monotonous colors, failure to produce shape brush handles, and raw materials that cannot meet performance requirements, etc., and achieve the effect of rich colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

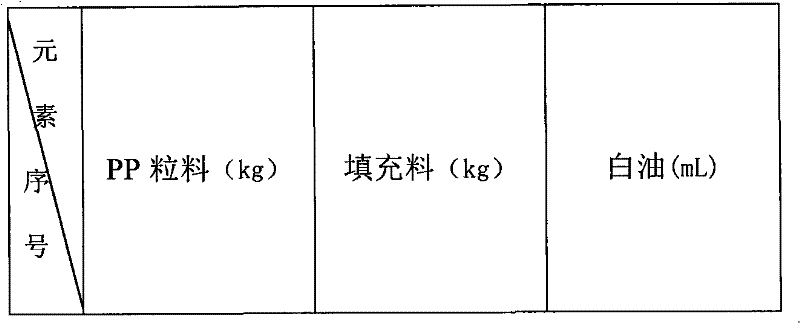

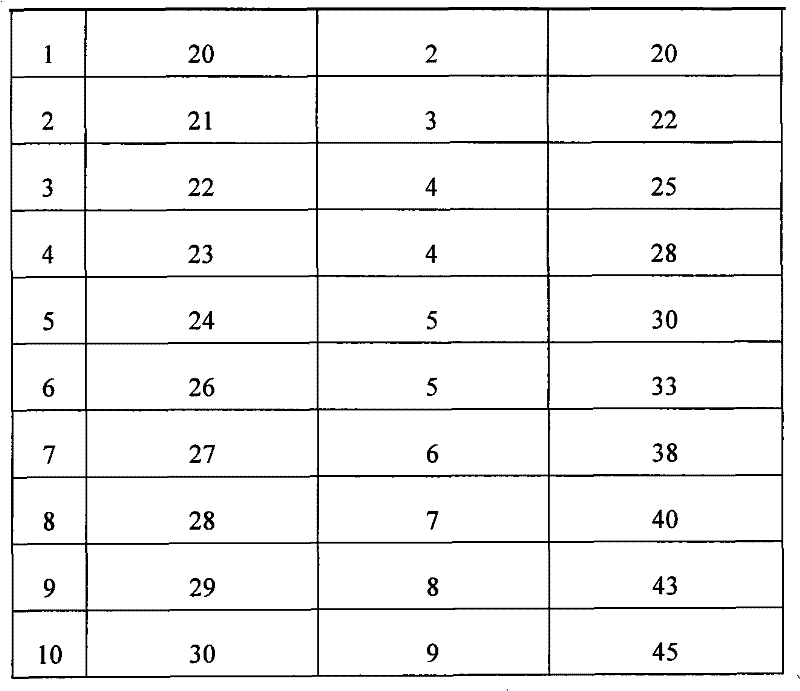

[0026] The raw materials required for the mixing of materials for one-time injection molding are 25kgPP pellets, 20% filling material, porcelain white powder and 30ml white oil. Use a clean rag to wipe the mixing tank of the mixer before mixing, then pour the PP pellets into the mixing tank of the mixer, add 20% filler, one part of porcelain white powder and 30ml of white oil. After all the required raw materials are poured into the mixing tank, the mixing operation starts. Turn on the mixing machine, and the mixing time is 3-6 minutes, so that the raw materials in the mixing tank are fully stirred evenly, that is, the mixing process of the injection molding material is completed once. Pack the injection molding raw materials that have completed a mixing process into a clean material bag for use in the first injection molding process.

[0027] Secondary injection molding materials are different from primary injection molding materials. The main material of primary injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com