Method for collecting dioxin from incineration flue gas of household garbage

A domestic waste incineration and flue gas technology, applied in the field of collection, can solve the problems of cumbersome mobile sampling, restricting the development of dioxin monitoring work, and long service cycle of equipment later maintenance. The effect of set efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

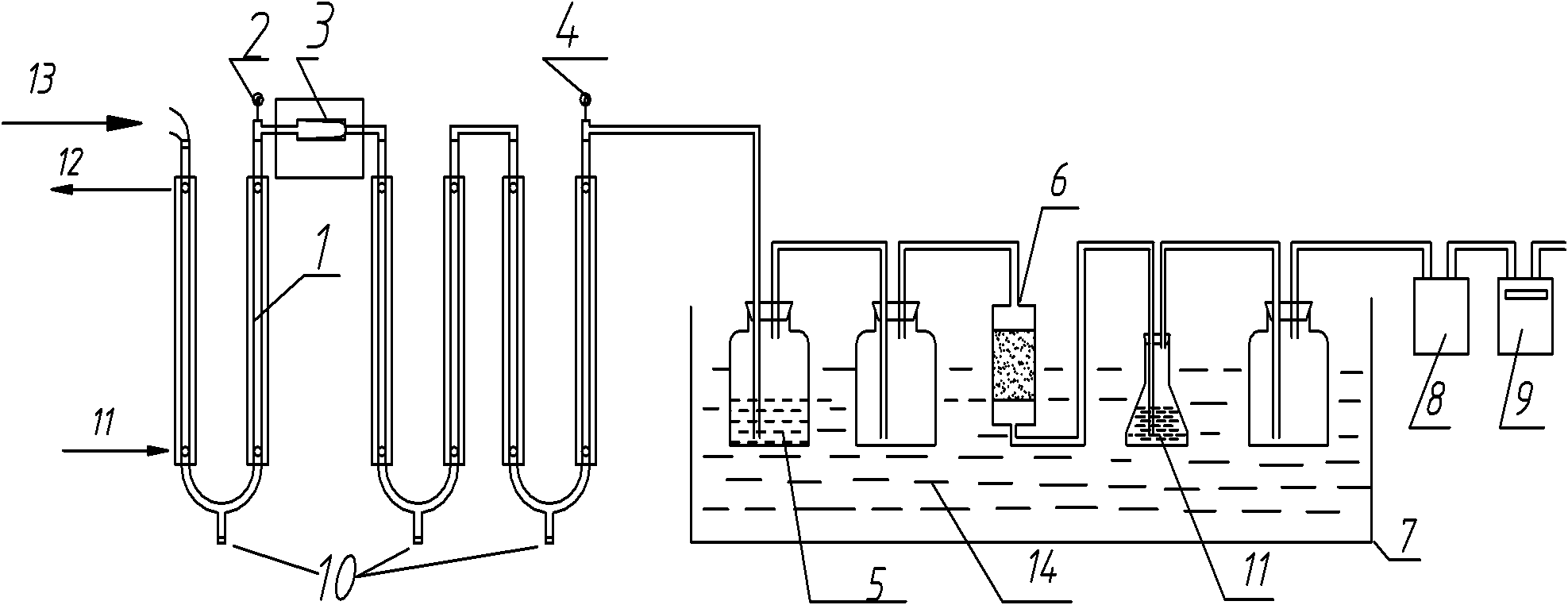

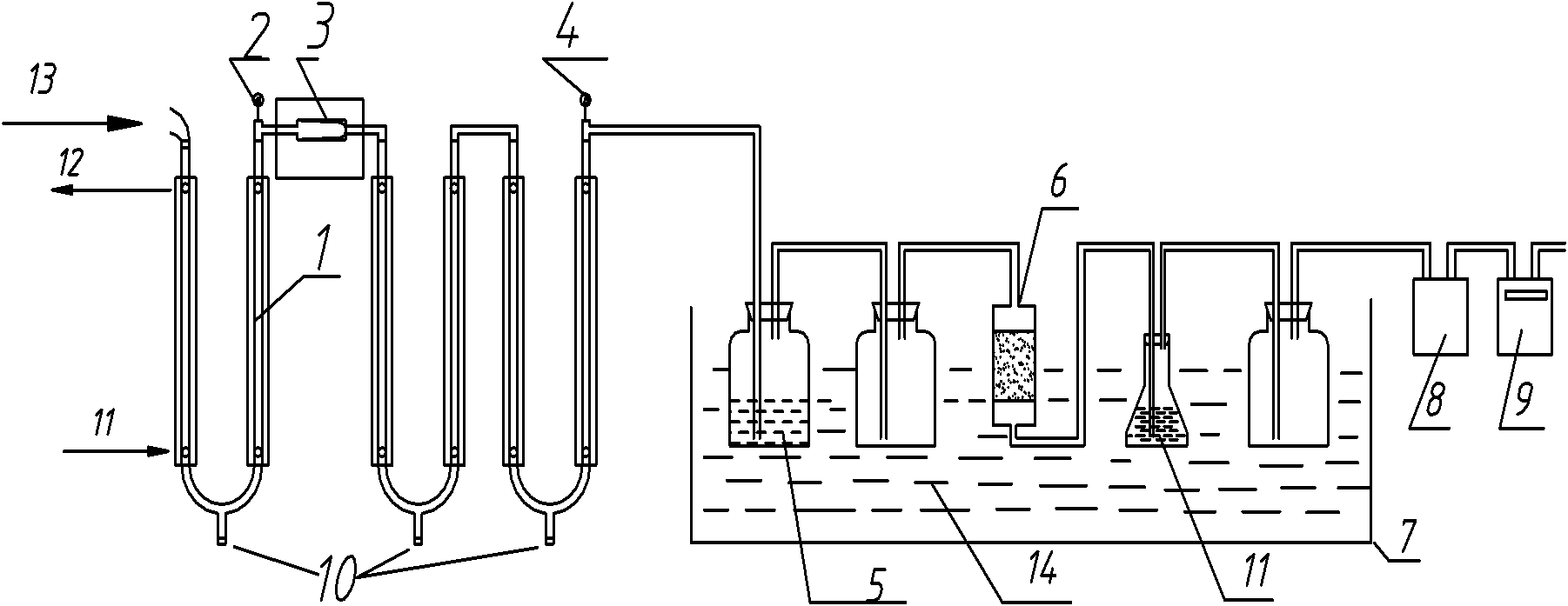

Embodiment 1

[0018] (1) Make the domestic waste incineration flue gas pass through the first-stage casing heat exchanger, the filter cartridge and at least one post-processing casing heat exchanger in sequence, and the temperature of the flue gas entering the filter cartridge is controlled at 105°C; (2 ) The flue gas flowing out from the last-stage treatment casing heat exchanger passes sequentially through the n-hexane scrubbing bottle with n-hexane washing water inside, the first buffer bottle, the glass filling tube with resin inside, and the glass filling tube with The toluene gas washing bottle and the second buffer bottle of toluene; the normal hexane gas washing bottle, the first buffer bottle, the glass filling tube that is equipped with resin in it, the toluene that is equipped with toluene in it. The gas washing bottle and the second buffer bottle are placed in the ice-water mixture 14; (3) adopt a vacuum pump to extract the flue gas passing through the second buffer bottle to obt...

Embodiment 2

[0021] (1) Make the domestic waste incineration flue gas pass through the first-stage casing heat exchanger, the filter cartridge and at least one post-processing casing heat exchanger in sequence, and the temperature of the flue gas entering the filter cartridge is controlled at 115°C; (2 ) The flue gas flowing out from the last-stage treatment casing heat exchanger passes sequentially through the n-hexane scrubbing bottle with n-hexane washing water inside, the first buffer bottle, the glass filling tube with resin inside, and the glass filling tube with The toluene gas washing bottle and the second buffer bottle of toluene; the normal hexane gas washing bottle, the first buffer bottle, the glass filling tube that is equipped with resin in it, the toluene that is equipped with toluene in it. The gas washing bottle and the second buffer bottle are placed in the ice-water mixture 14; (3) adopt a vacuum pump to extract the flue gas passing through the second buffer bottle to obt...

Embodiment 3

[0024] (1) Make the flue gas from domestic waste incineration pass through the first-stage casing heat exchanger, the filter cartridge and at least one post-processing casing heat exchanger in sequence, and the temperature of the flue gas entering the filter cartridge is controlled at 110°C; (2 ) The flue gas flowing out from the last-stage treatment casing heat exchanger passes sequentially through the n-hexane scrubbing bottle with n-hexane washing water inside, the first buffer bottle, the glass filling tube with resin inside, and the glass filling tube with The toluene gas washing bottle and the second buffer bottle of toluene; the normal hexane gas washing bottle, the first buffer bottle, the glass filling tube that is equipped with resin in it, the toluene that is equipped with toluene in it. The gas washing bottle and the second buffer bottle are placed in the ice-water mixture 14; (3) adopt a vacuum pump to extract the flue gas passing through the second buffer bottle t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com