Application method of magnesium oxide microsphere in environmental water sample

An application method and technology of magnesium oxide, which can be used in measuring devices, instruments, scientific instruments, etc., can solve the problems of unfavorable effects, high cost, and complicated preparation process of solid-phase extraction adsorbents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] (3) Preparation of solid-phase extraction column: select magnesium oxide microspheres with a particle size of less than 320 meshes and fill them into empty solid-phase extraction tubes by dry method, and place matching filter sieve plates on the upper and lower sides respectively.

[0023] (4) Column balance: Use non-polar organic solvents, organic modifiers, and an aqueous solution of organic modifiers with a volume ratio of 0-30% to carry out column balance for the solid-phase extraction column in order to remove the solid-phase extraction adsorbent impurities contained in it.

[0024] (5) Sample loading: pass the water sample to be tested through the solid phase extraction column at a certain flow rate.

[0025] (6) Rinse: rinse with 3mL deionized water to remove retained or adsorbed polar compounds. After the rinsing is completed, use a vacuum pump to fully drain the water in the solid phase extraction tube to prevent the remaining water from affecting the next ste...

Embodiment 1

[0029] Fill 200 mg of magnesium oxide microspheres into an empty solid-phase extraction tube (6 mL) by dry method, and place matching filter sieves on the top and bottom respectively. Before sample loading, equilibrate the solid-phase extraction column with dichloromethane, methanol, and water respectively; then dilute 1 mL of PAHs standard solution with deionized water to 20 mL (containing phenanthrene 14 μg / L, anthracene 11 μg / L, pyrene 31.5 μg / L L, benzo[a]pyrene 16.5 μg / L, dibenzoanthracene 12 μg / L), be prepared into the solution to be tested; then the prepared solution to be tested is passed through the solid-phase extraction column at a flow rate of 1.0mL / min, after that Rinse with 3mL of deionized water. After the rinsing is completed, use a vacuum pump to fully drain the water in the solid-phase extraction tube, and then use 5mL of dichloromethane to extract the substances to be tested (phenanthrene, anthracene, pyrene, benzo[a]pyrene, Dibenzanthracene) eluted. After ...

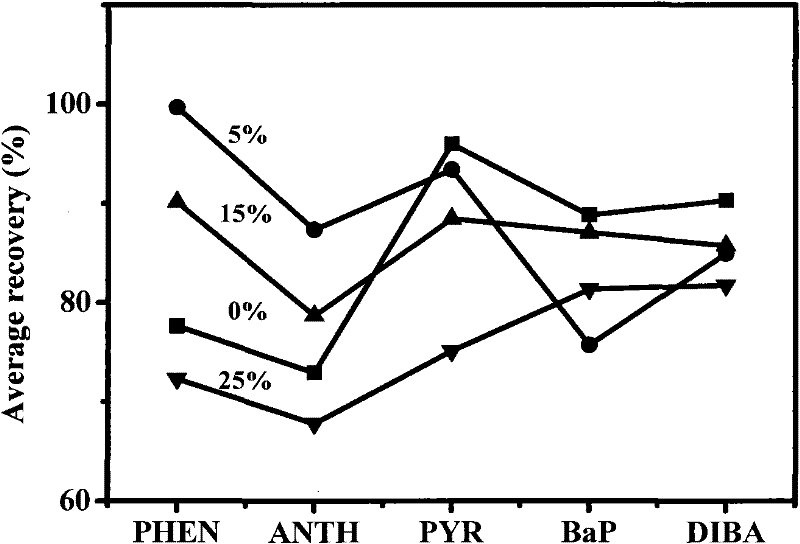

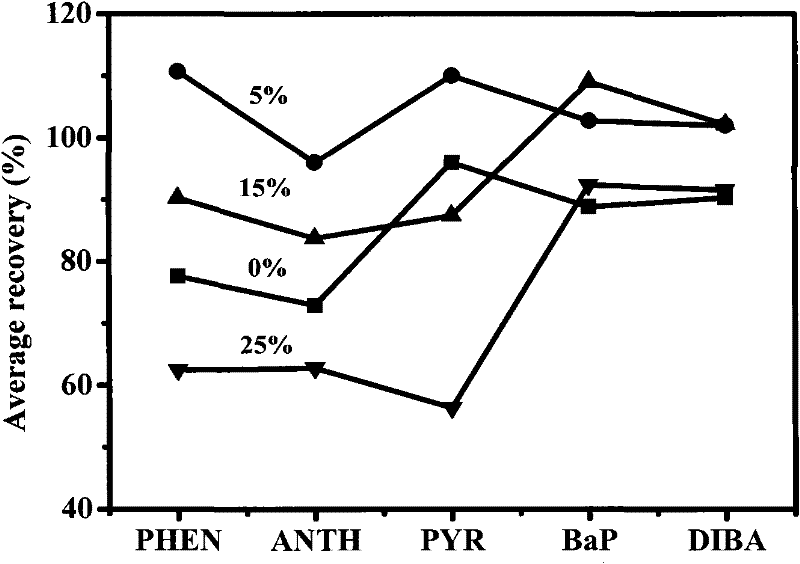

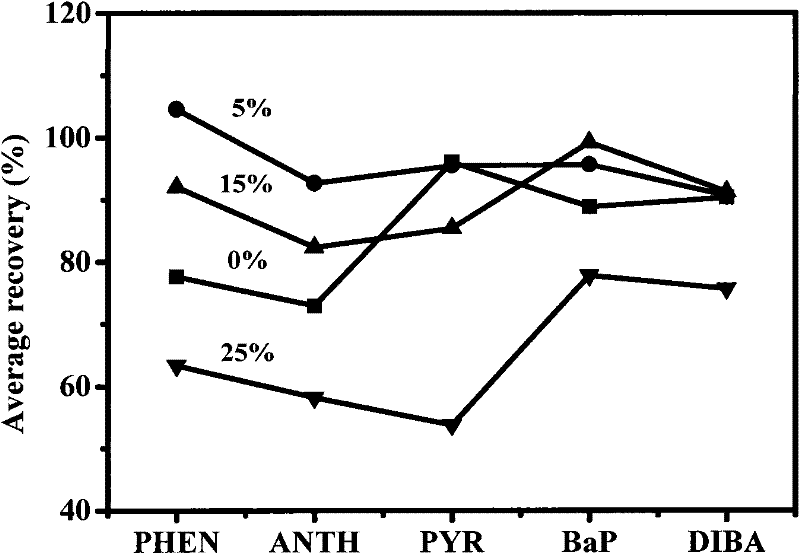

Embodiment 2

[0031]Fill 200 mg of magnesium oxide microspheres into an empty solid-phase extraction tube (6 mL) by dry method, and place matching filter sieves on the top and bottom respectively. Before sample loading, use dichloromethane, methanol and three volume ratios (5%, 15%, 25%) of methanol aqueous solution to equilibrate the three solid-phase extraction columns; (1mL, 3mL, 5mL) was diluted with deionized water to 20mL (containing phenanthrene 14μg / L, anthracene 11μg / L, pyrene 31.5μg / L, benzo[a]pyrene 16.5μg / L, dibenzoanthracene 12μg / L ), so that the content of methanol in the aqueous solution is respectively (a) 5% (b) 15% (c) 25%, thereby being mixed with different solutions to be tested; Pass through the corresponding three solid-phase extraction columns respectively, and then rinse with 3mL deionized water. After the rinse is completed, use a vacuum pump to fully drain the water in the solid-phase extraction tube, and then use 5mL of dichloromethane to extract the substance to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com