Binder as well as application thereof in catalyst for removing nitric oxide in smoke gas

A nitrogen oxide and binder technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as aggravating NOX emissions and ammonia penetration , to achieve the effect of good denitration performance, simple application method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 5g MnO x -V 2 o 5 / TiO 2 -CNTs catalyst powder, 0.3g organic bentonite and 0.7g composite Portland cement are mixed evenly, add appropriate amount of water and stir to make a slurry, and evenly coat on a rectangular aluminum sheet with a rough surface of 3.5cm×10cm×0.1cm Both sides were placed at room temperature for a period of time. After drying, the catalyst sheet was placed in a muffle furnace at 300°C for 1 hour, and then cooled with the furnace.

[0021] The laboratory simulates the working environment of commercial catalyst sheets, using 5m / s parallel wind to blow sheet-shaped catalysts, such as figure 1 , to examine its powder drop rate in one hour to measure its strength. Soak the sheet catalyst in water completely, and examine its powder shedding rate in one hour to measure its water resistance. Wherein, powder shedding rate = lost catalyst mass / catalyst quality coated on the sheet catalyst, the smaller the powder shedding rate, the better its streng...

Embodiment 2

[0023] Take 5g of MnOx-CeOx / TiO2-CNTs catalyst powder, 0.3g of organobentonite and 0.6g of composite Portland cement, mix evenly, add appropriate amount of water and stir to make a slurry, and evenly coat on 3.5cm×10cm×0.1cm The two sides of the rectangular iron sheet with rough surface were placed at room temperature for a period of time. After drying, the catalyst sheet was placed in a muffle furnace at 300°C for 1 hour, and then cooled with the furnace.

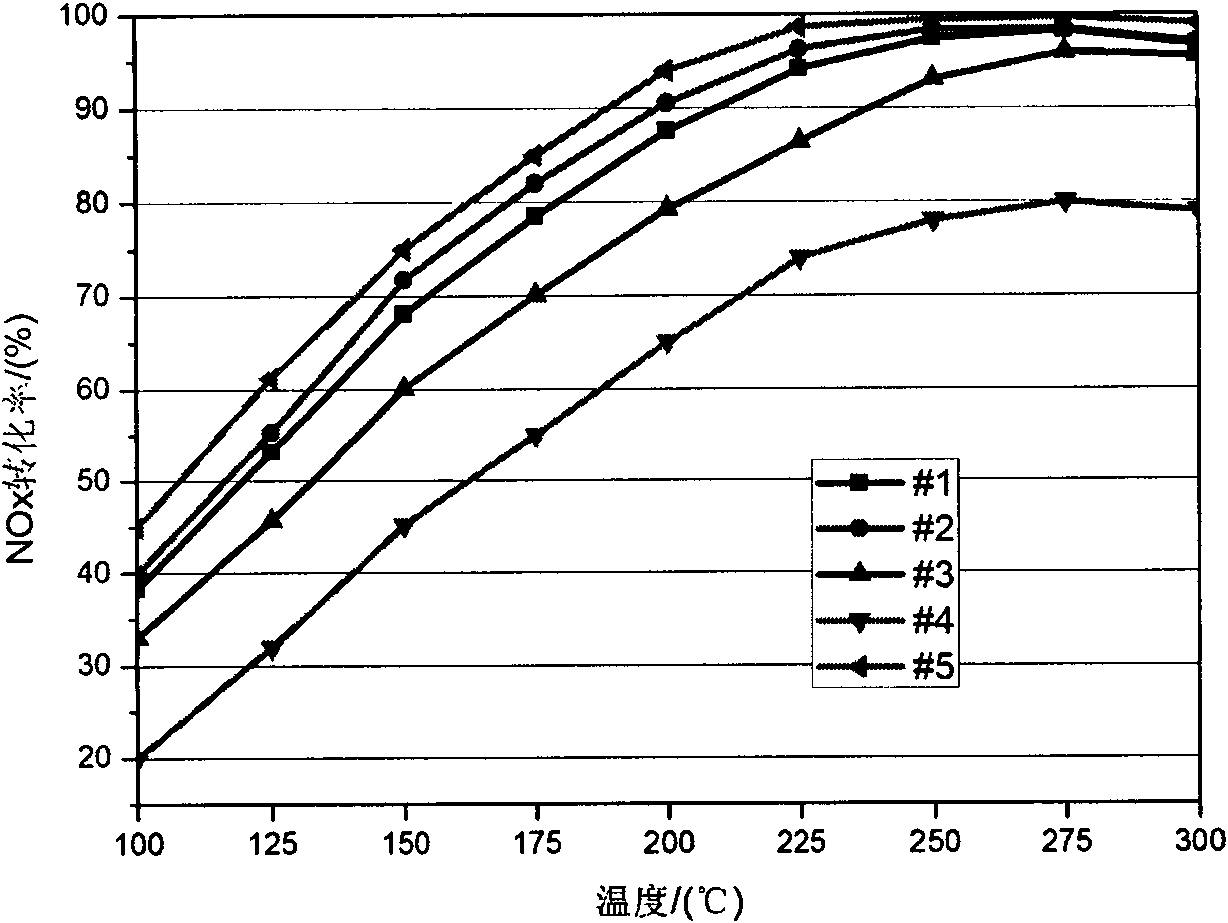

[0024] Intensity, water resistance and out-of-stock performance test methods and conditions are the same as in Example 1. When measuring the strength, the powder dropping rate is 7.25%, and when measuring the water resistance, the powder dropping rate is 14.58%. The denitrification performance test results are as follows: figure 2 In the #2 curve, at 250°C, the conversion rate of NOx is above 98%.

Embodiment 3

[0026] Take 5g MnO x -CeO x / TiO 2 Catalyst powder, 0.5g organic bentonite and 0.7g composite Portland cement are mixed evenly, add appropriate amount of water and stir to make a slurry, and evenly coat both sides of a rectangular aluminum sheet with a rough surface of 3.5cm×10cm×0.1cm. Stand at room temperature for a period of time, and after drying, put the catalyst sheet into a muffle furnace at 300°C for 1 hour, and then cool down with the furnace.

[0027] Intensity, water resistance and out-of-stock performance test methods and conditions are the same as in Example 1. When measuring the strength, the powder dropping rate is 6.02%, and when measuring the water resistance, the powder dropping rate is 15.56%. The denitrification performance test results are as follows: figure 2 In the #3 curve, at 275°C, the conversion rate of NOx is above 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com