Recovery unit of gear surface processing auxiliary oil

A surface processing and recovery device technology, which is applied to gear teeth manufacturing devices, metal processing equipment, belts/chains/gears, etc., can solve the problems of waste processing auxiliary oil, worker allergies, and damage to workers' health, so as to save processing auxiliary oil , to avoid the effect of drying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is further described:

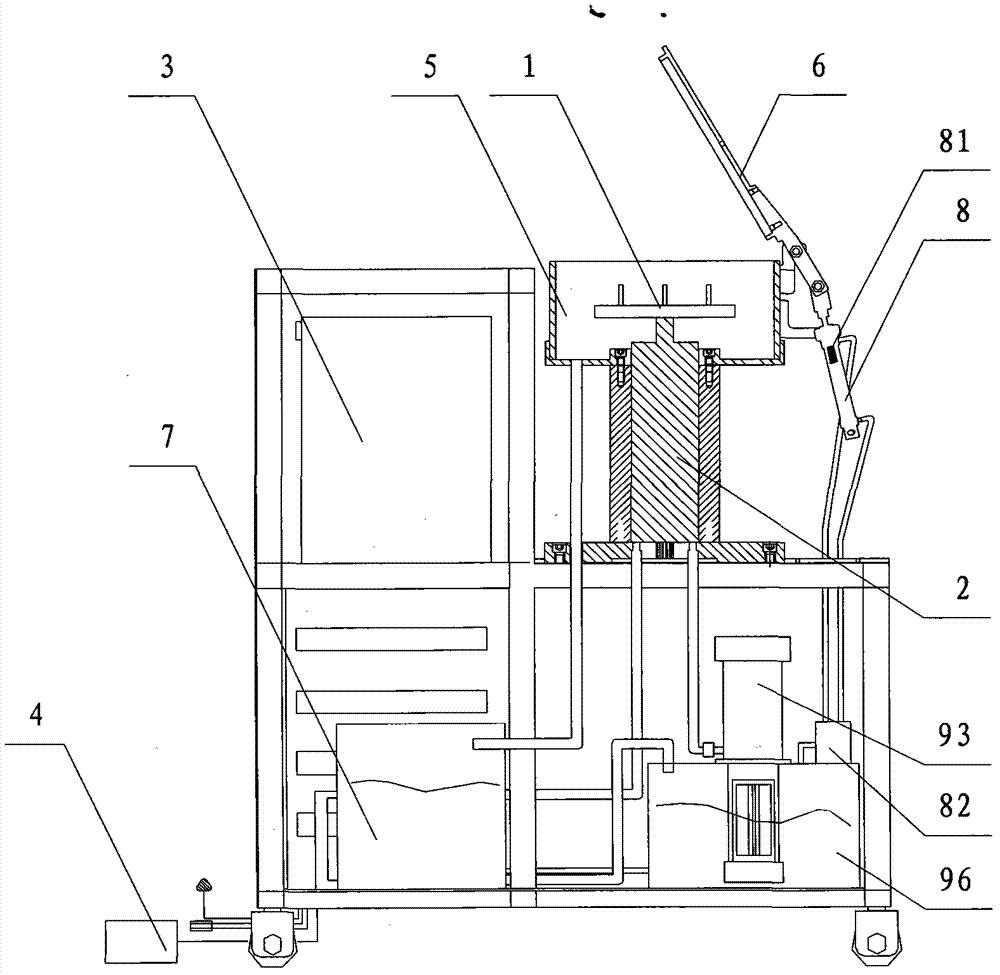

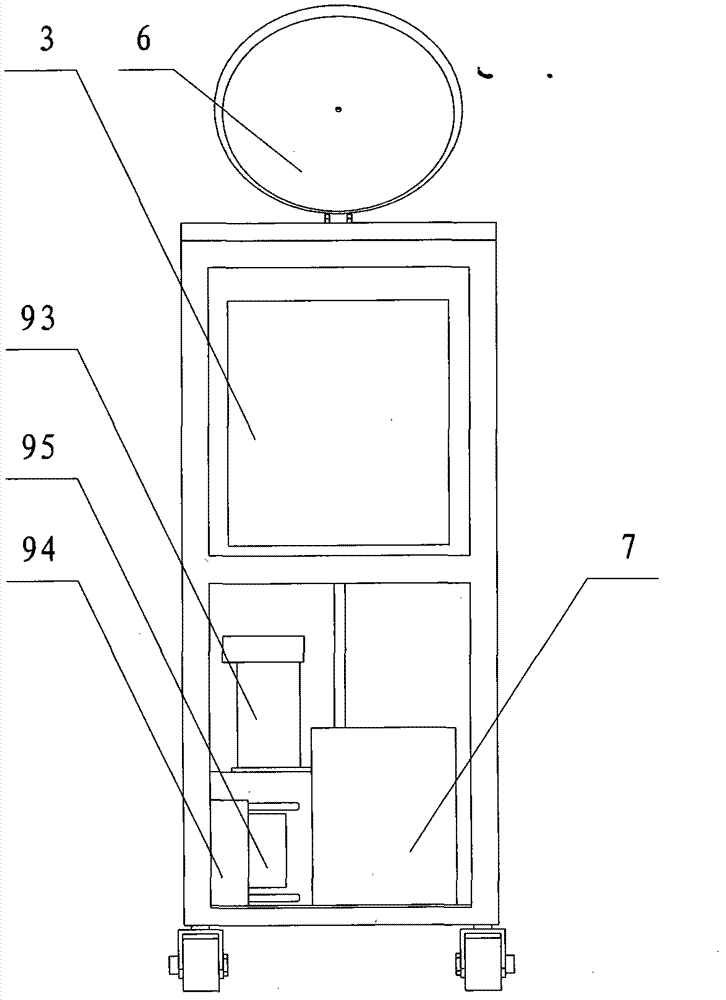

[0021] like figure 1 and figure 2 As shown, the present invention provides an auxiliary oil recovery device for gear surface processing, including: a vertically arranged gear fixing tool 1, a high-speed motor 2, a single-chip microcomputer 3, a pedal signal switch 4, an oil collection cylinder 5, and a protective cover 6 , oil storage tank 7, cylinder 8, displacement sensor 81, solenoid valve 82 and water cooling system; wherein, the upper end of the gear fixing tool 1 is matched with the gear, the lower end is connected with the high-speed motor 2, and the oil liquid collection cylinder 3 is arranged on the gear fixing shaft On the periphery of the upper end, one side of the protective cover 6 is hinged on the oil collection tube 5, and the protective cover 6 at the hinge is provided with an extended end, and the shell of the cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com