Reinforced concrete corrosion inhibitor and preparation and application thereof

A technology of reinforced concrete and rust inhibitor, applied in the field of rust inhibitor, can solve the problems of insufficient structural design resistance, insufficient structural durability, failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

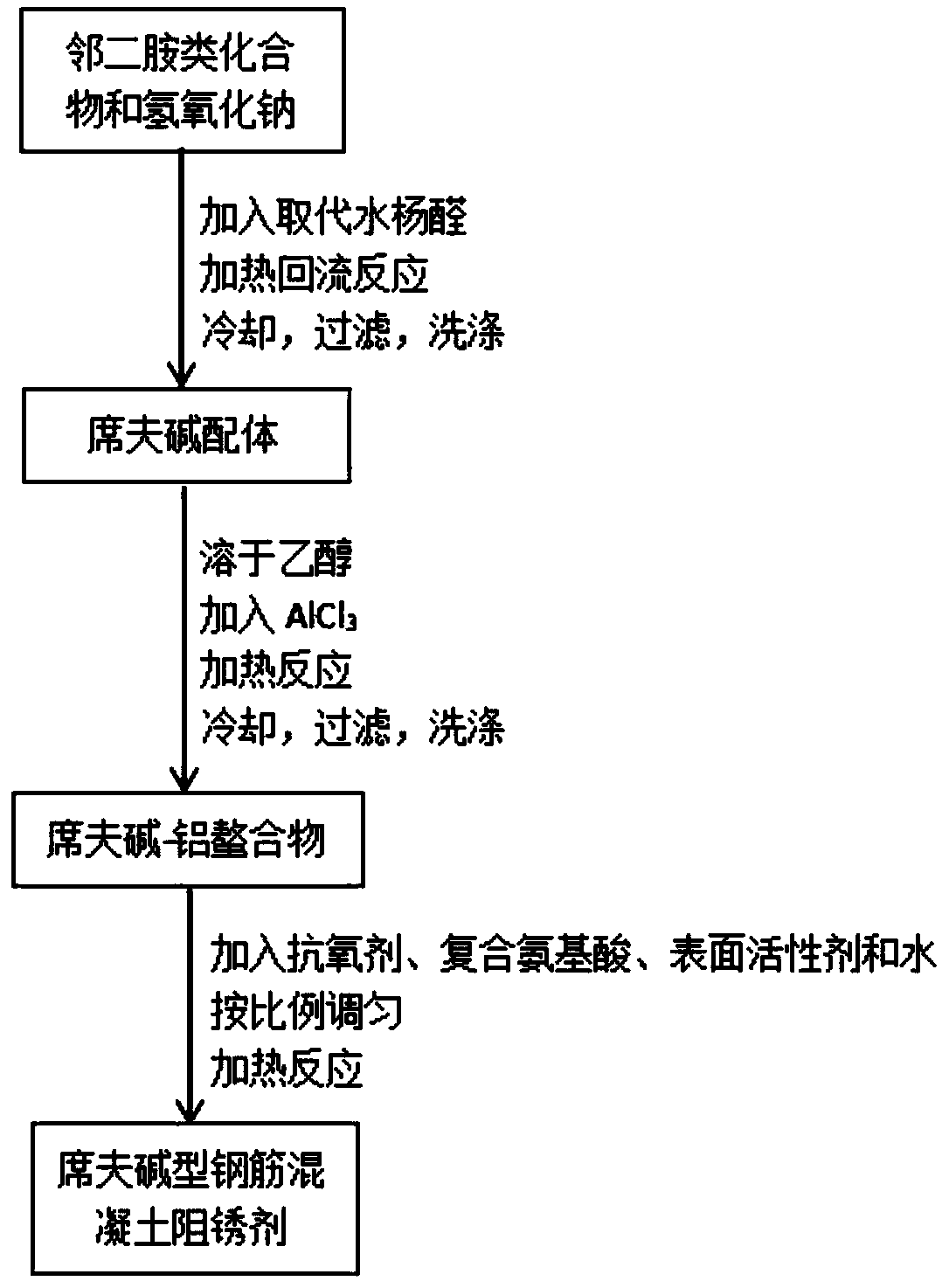

Method used

Image

Examples

Embodiment 1

[0027] The preparation of embodiment 1 reinforced concrete rust inhibitor

[0028] Composition of raw materials: 30 parts of Schiff base-aluminum chelate, 20 parts of tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and didodecyl alcohol ester, compound Amino acid (lysine and glycine, mass ratio is 2:1) 20 parts, dialkyl sulfate ester quaternary ammonium salt cationic surfactant 10 parts and water 50 parts;

[0029] Preparation:

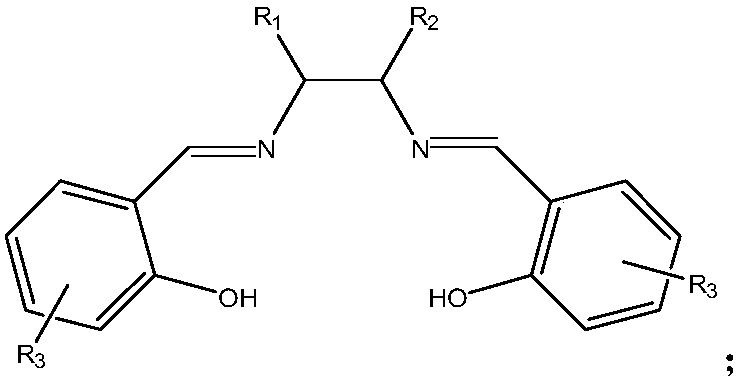

[0030] S1. Synthesis of Schiff base ligands: Dissolve 1 mol of o-diamine compound and 0.1 mol of sodium hydroxide in acetonitrile, add 1.8 mol of salicylaldehyde, heat and reflux for 5 hours to produce a white solid, continue to reflux for 1 hour Cool to room temperature, filter, and wash the solid repeatedly with ethanol to obtain the Schiff base ligand, the structural formula is:

[0031]

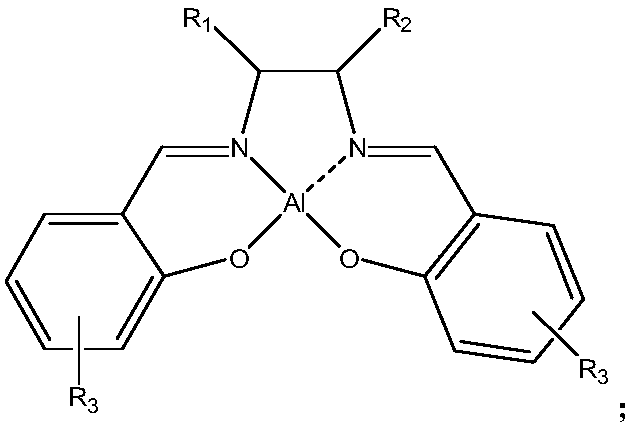

[0032] S2. Synthesis of Schiff base-aluminum chelate: Dissolve the Schiff base ligand in ethanol solution, add AlCl 3 , ...

Embodiment 2

[0038] The preparation of embodiment 2 reinforced concrete rust inhibitor

[0039] Raw material composition: 50 parts of Schiff base-aluminum chelate, 20 parts of trioctyl ester, 20 parts of tridecyl ester, 40 parts of compound amino acid (methionine and glycine, mass ratio 1:1), halogenated hydrocarbon quaternary ammonium salt cation 20 parts of surfactant and 60 parts of water;

[0040] Preparation:

[0041] S1. Synthesis of Schiff base ligands: Dissolve 1 mol of o-diamine compound and 0.1 sodium hydroxide in dichloromethane, add 2 mol of salicylaldehyde, heat and reflux for 7 hours to produce a white solid, continue to reflux for 1 hour Cool to room temperature, filter, and wash the solid repeatedly with ethanol to obtain the Schiff base ligand;

[0042] S2. Synthesis of Schiff base-aluminum chelate: Dissolve the Schiff base ligand in ethanol solution, add AlCl 3 , react at 70°C for 24h, cool and filter, and wash the solid repeatedly with ethanol to obtain a Schiff base-...

Embodiment 3

[0044] The preparation of embodiment 3 reinforced concrete rust inhibitor

[0045] Composition of raw materials: 40 parts of Schiff base-aluminum chelate, 30 parts of 2,6-tertiary butyl-4-methylphenol, compound amino acids (diglycine, triglycine and tyrosine, the mass ratio is 1:1 : 1) 30 parts, 15 parts of alkylene oxide quaternary ammonium salt cationic surfactants and 55 parts of water;

[0046] Preparation:

[0047] S1. Synthesis of Schiff base ligand: Dissolve 1 mol of o-diamine compound and 0.1 sodium hydroxide in methanol, add 2.2 mol to replace salicylaldehyde, heat and reflux for 6 hours to produce a white solid, continue to reflux for 1 hour and then cool to room temperature, filtered, and the solid was repeatedly washed with ethanol to obtain the Schiff base ligand;

[0048] S2. Synthesis of Schiff base-aluminum chelate: Dissolve the Schiff base ligand in ethanol solution, add AlCl 3 , react at 60°C for 18h, cool and filter, and wash the solid repeatedly with eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com