Aluminum foil and copper foil no-clean oily cutting fluid and preparation method thereof

A cleaning-free, cutting fluid technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of increasing processing cost and time, complicated processes, etc., and achieve the effect of expanding the scope of use, eliminating the cleaning process, and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the above-mentioned aluminum foil and copper foil no-cleaning oily cutting fluid comprises the following steps:

[0033] (1) Accurately weigh each raw material required for preparing cutting fluid according to the proportioning ratio;

[0034] (2) Add the weighed light mineral oil, long-chain olefin, and polyfatty acid ester into the stirring tank successively, and fully stir for 30min to 90min under normal temperature and pressure to obtain the first mixture solution;

[0035] (3) Mix the antirust agent and alkanol and fully stir at normal temperature and pressure, until the antirust agent is completely dissolved in the alkanol, the stirring can be stopped to obtain the second mixture solution;

[0036] (4) Add the second mixture solution into the first mixture solution, and fully stir at normal temperature and pressure for 1-2 h to obtain the no-cleaning oily cutting fluid for aluminum foil and copper foil.

[0037] Unless otherwise specifie...

Embodiment 1

[0039] Weigh the following components respectively:

[0040] Table 1 Embodiment 1 Proportion of materials (mass percentage)

[0041] light mineral oil 90% dodecene 6% Dodecanol 2% Polyhydroxyalkanoate 1% Rust inhibitor 1%

[0042] The preparation steps of aluminum foil and copper foil no-cleaning oily cutting fluid are as follows:

[0043] (1) Accurately weigh each raw material required for preparing cutting fluid according to the proportioning ratio;

[0044] (2) The weighed light mineral oil, dodecene, and polyhydroxyalkanoate are added in the stirred tank successively, and fully stirred for 30min under normal temperature and pressure to obtain the first mixture solution;

[0045] (3) Mix the antirust agent and dodecyl alcohol and fully stir for 30 minutes at normal temperature and pressure to obtain the second mixture solution;

[0046] (4) Add the second mixture solution into the first mixture solution, and fully stir for 1 hour at ...

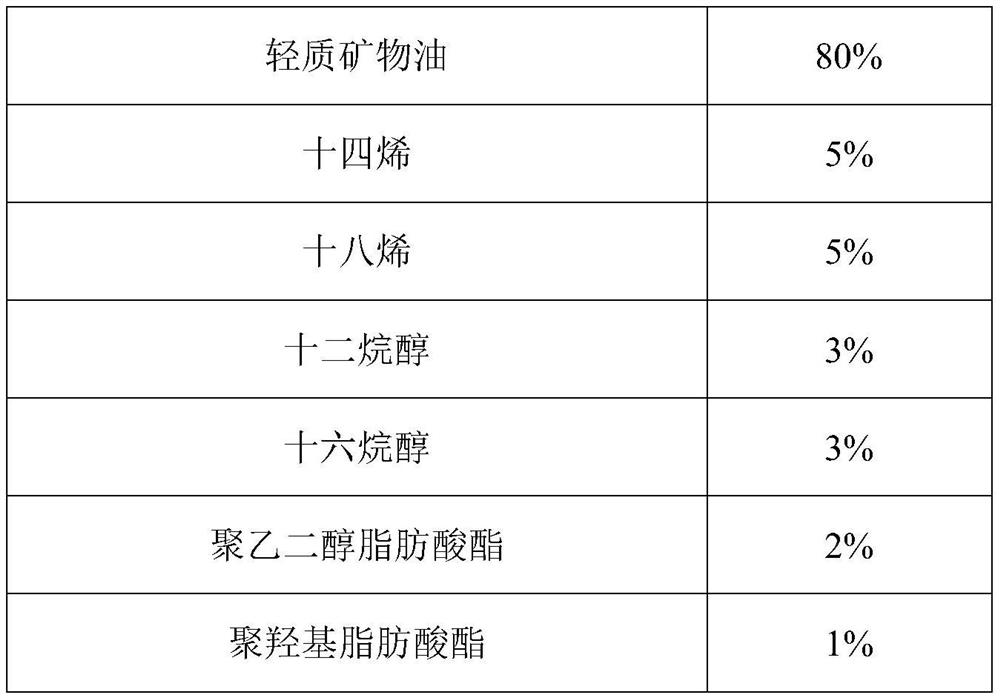

Embodiment 2

[0048] Weigh the following components respectively:

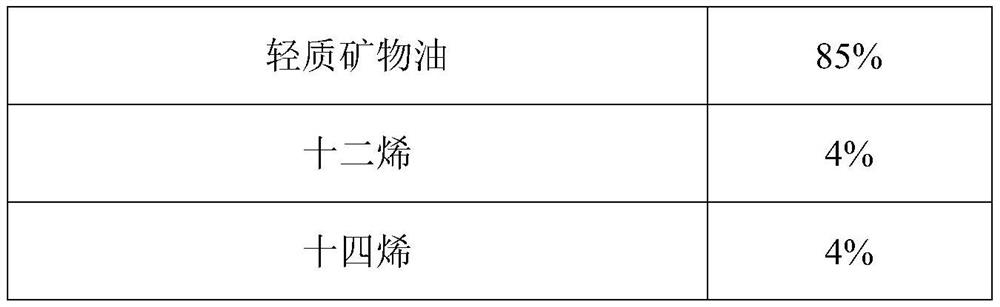

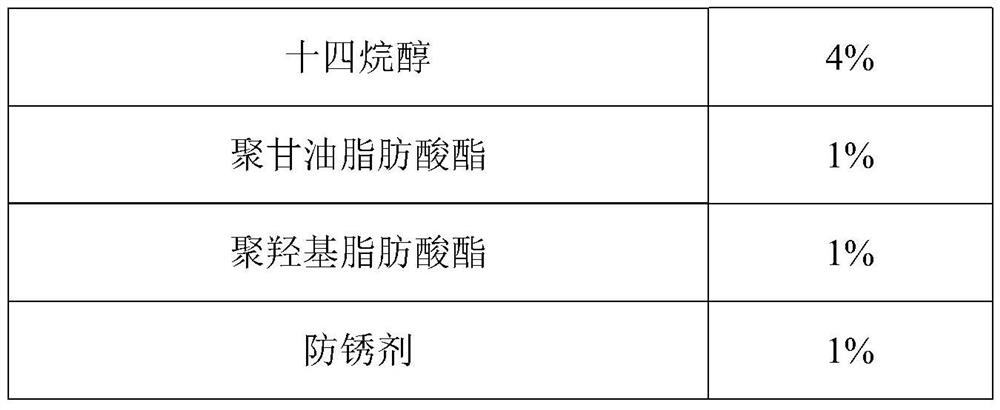

[0049] Table 2 Embodiment 2 Proportion of materials

[0050]

[0051]

[0052]The preparation steps of aluminum foil and copper foil no-cleaning oily cutting fluid are as follows:

[0053] (1) Accurately weigh each raw material required for preparing cutting fluid according to the proportioning ratio;

[0054] (2) Add the weighed light mineral oil, dodecene, tetradecene, polyglycerol fatty acid ester and polyhydroxy fatty acid ester into the stirring tank in turn, and fully stir for 30 minutes under normal temperature and pressure to obtain the first mixture solution ;

[0055] (3) Mix the antirust agent and myristyl alcohol and fully stir for 30 minutes at normal temperature and pressure to obtain the second mixture solution;

[0056] (4) Add the second mixture solution into the first mixture solution, and fully stir for 1 h at normal temperature and pressure,

[0057] The system is uniform, transparent and clear...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com