Circulating water treatment device and process using nanocrystalline titanium dioxide fiber photocatalysis reactor

A photocatalytic reactor, titanium dioxide technology, which is applied in the directions of oxidized water/sewage treatment, illumination water/sewage treatment, energy and wastewater treatment, etc., can solve the problems of inconvenient fiber assembly, large light transmission loss, and reduced water flow cross-sectional area, etc. Achieve the effect of avoiding fiber breakage and loss, smooth and slow rise of water flow, and increase of water flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

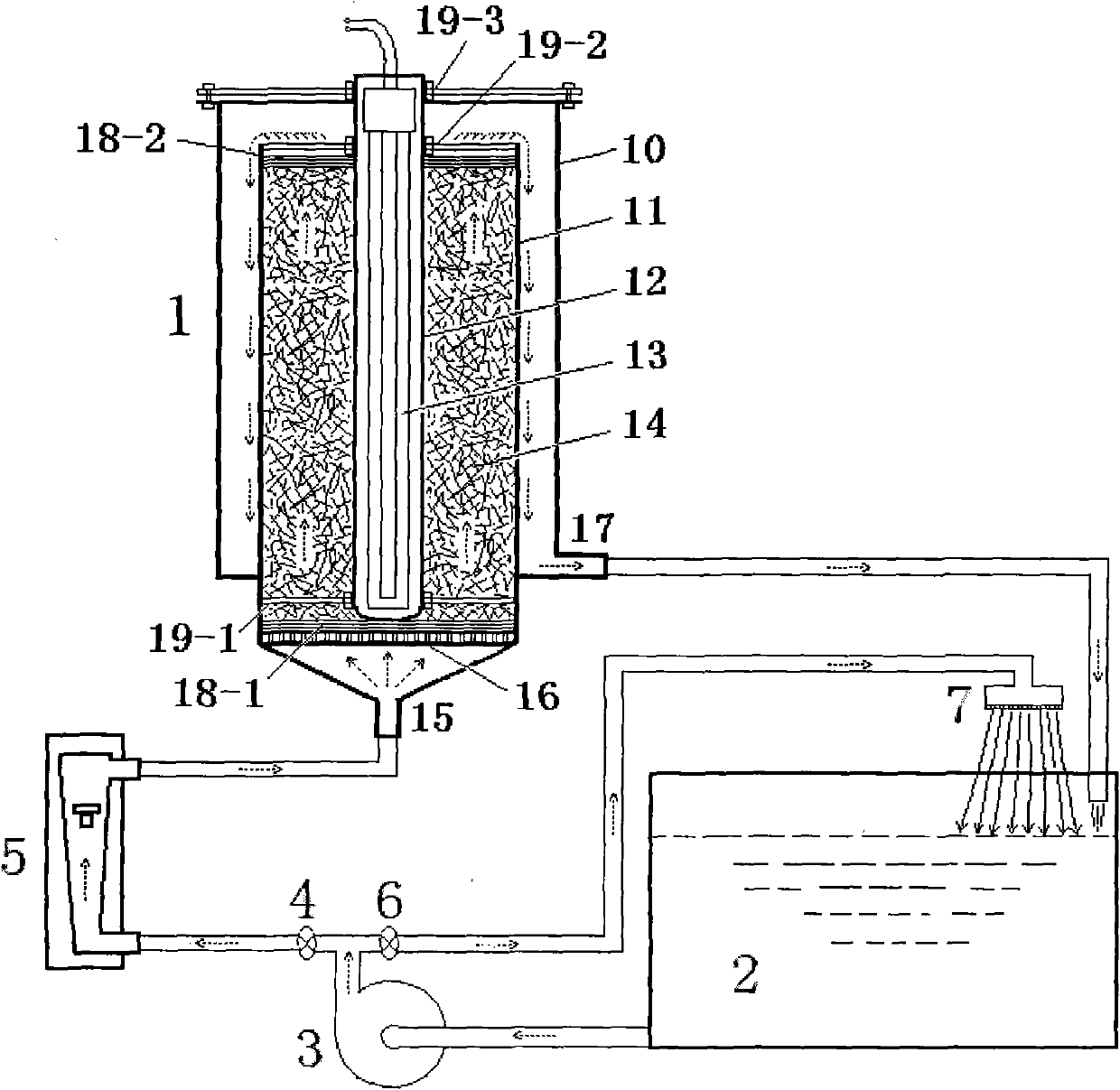

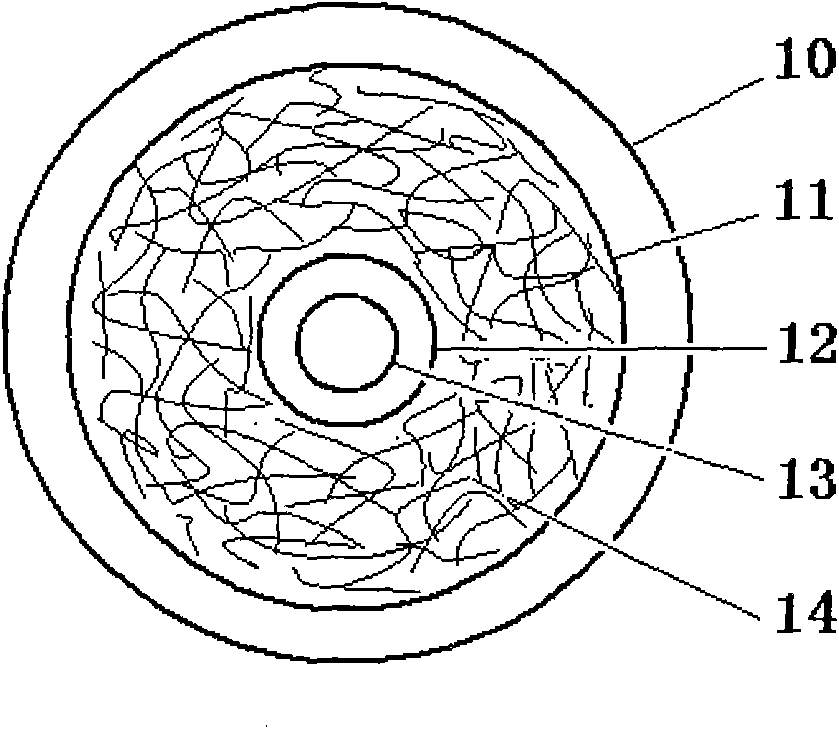

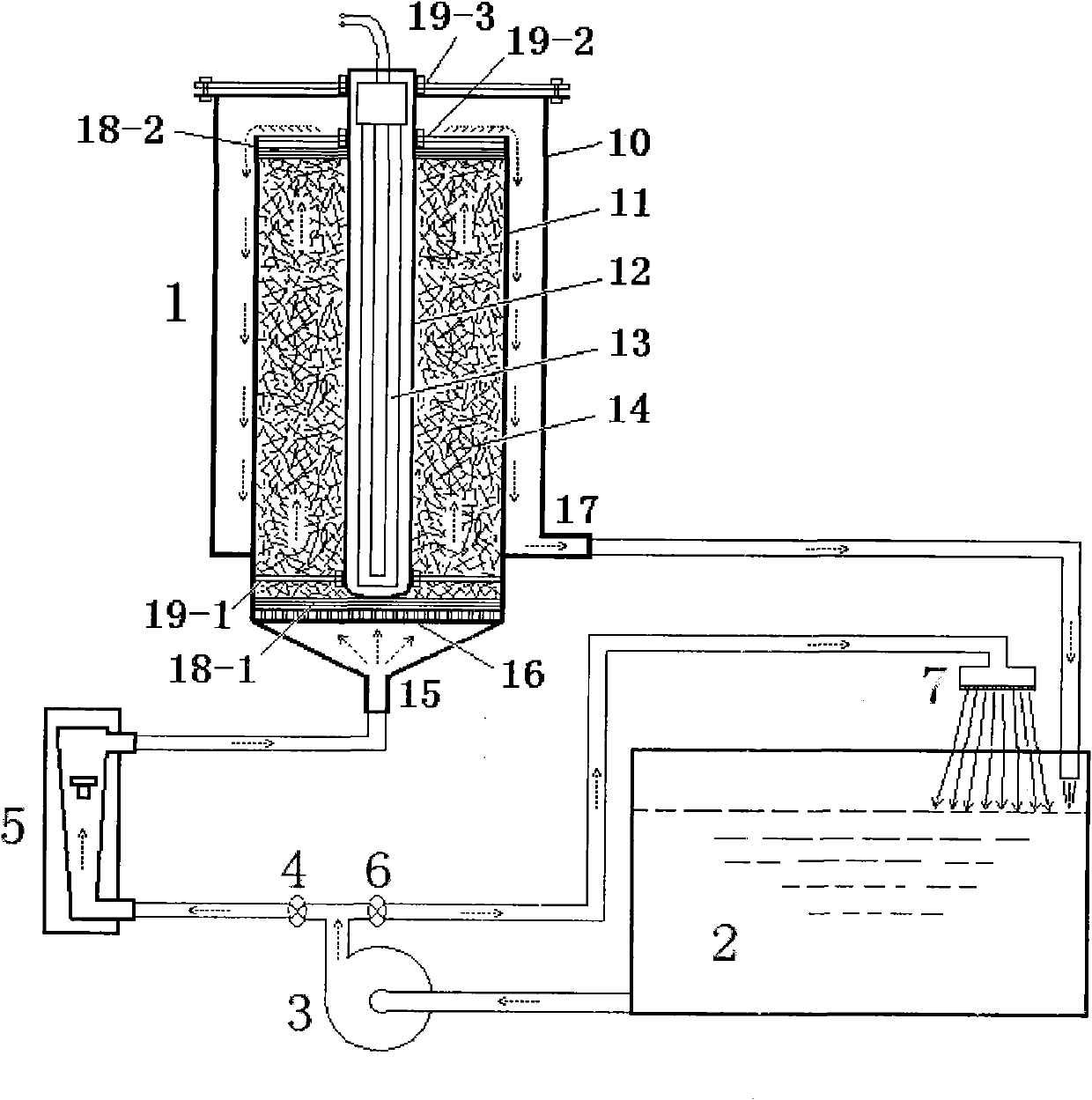

[0020] combine figure 1 , the present invention utilizes the circulating water treatment device of nanocrystalline titanium dioxide fiber photocatalytic reactor, consists of nanocrystalline titanium dioxide fiber photocatalytic reactor 1, water storage tank 2, water pump 3, first valve 4, flowmeter 5, second valve 6 and The spray aerator head 7 forms a water circulation circuit; wherein, the water outlet of the water storage tank 2 is connected with the water inlet of the water pump 3, and the water outlet of the water pump 3 is divided into two paths, one of which is connected with the first valve 4, and the other is connected with the second valve 6 , the first valve 4 is connected to the water inlet of the flow meter 5, the water outlet of the flow meter 5 is connected to the water inlet of the nanocrystalline titanium dioxide fiber photocatalytic reactor 1, and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com