Combined rural sewage treatment process and system

A technology of rural sewage and treatment process, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. , to achieve the effect of convenient management, saving operating costs and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

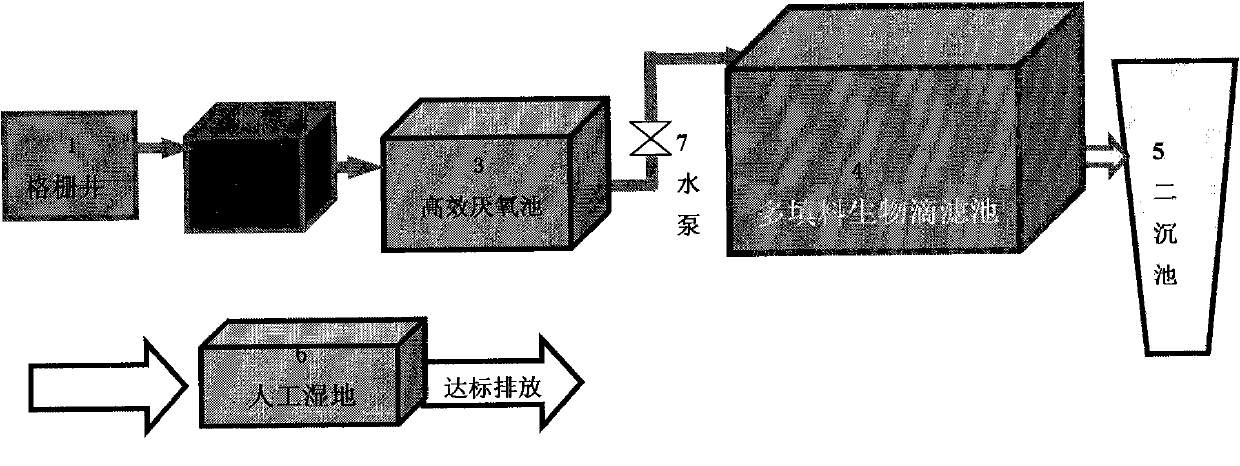

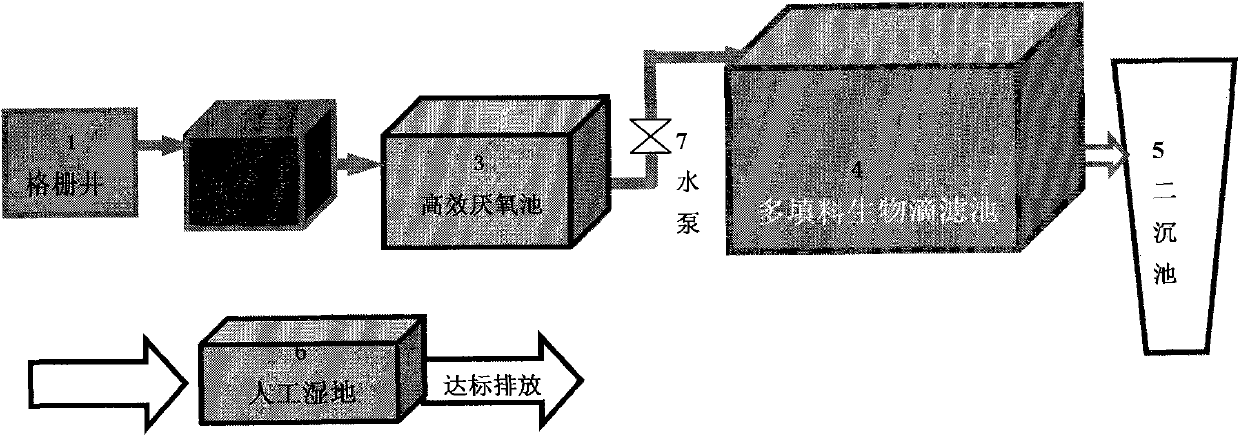

[0017] Embodiment one: see figure 1 , the treatment steps of this composite rural sewage treatment process are as follows:

[0018] 1) Wastewater is treated by high-efficiency anaerobic reaction: after the waste water is pretreated by grit chamber 2 from grid well 1, it is treated by high-efficiency anaerobic reaction in high-efficiency anaerobic pond 3, that is, it is hydrolyzed by acidifying bacteria in high-efficiency anaerobic reactor Decomposition, hydrolysis and acidification, gradually decomposed into organic acids, alcohols and small molecular organic substances, and then further converted into methane and carbon dioxide by methanogenic bacteria;

[0019] 2) Multi-filler biological filtration treatment: the wastewater treated by high-efficiency anaerobic reaction, under the lifting action of the pump 7, enters the multi-filler bio-trickling filter 4 for treatment by the spray system, and the multi-filler bio-filler in the pool degrades organic pollution substances and...

Embodiment 2

[0021] Embodiment two: see Figure 1 , this composite rural sewage treatment system is applied to the above sewage treatment process, including a high-efficiency anaerobic tank 3 and a multi-filler biological trickling filter 4, and the outlet of a grid well 1 is connected to the high-efficiency anaerobic tank through a grit chamber 2 The inlet of the oxygen tank 3, the outlet of the high-efficiency anaerobic tank 3 is connected to the spray system on the top of the multi-filler biological trickling filter 4 through a pump 7, and the outlet of the multi-filler biological trickling filter 4 passes through a pump 7 The secondary settling tank 5 is connected to a constructed wetland 6, and the constructed wetland 6 discharges up-to-standard purified water.

[0022] The pool structure of the multi-filler biological trickling filter: adopts an open network multilayer structure, which is a layered module structure, with 8 layers in total; each layer of module structure is supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com