Process for treating coal chemical waste water

A technology of coal chemical wastewater and treatment process, which is applied in water/sewage multi-stage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that activated carbon pores cannot be fully utilized and activated carbon adsorption capacity is not sufficient Play and other problems to achieve the effect of improved biodegradability and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

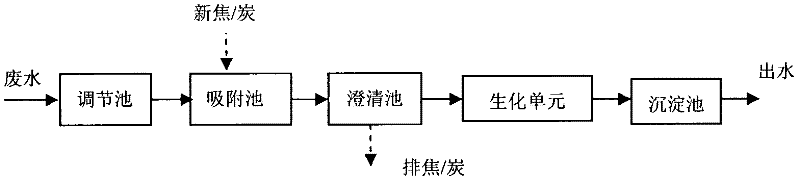

[0029] figure 1 , figure 2 A specific embodiment of the coal chemical industry wastewater treatment process described in the present invention is given. The coal chemical industry wastewater is stored in a wastewater regulating pool, and the regulating pool can make the sewage water quality in the pool uniform, and can also adjust the water output at the same time . The coal chemical wastewater treatment process adopts a wastewater treatment method that combines active material adsorption and biochemical treatment, including the following steps:

[0030] ① Pass the coal chemical industry wastewater in the adjustment pool into the adsorption pool, in which active coke adsorption materials are continuously added, and the coal chemical industry wastewater is adsorbed through the activated coke, and the coal chemical industry wastewater flows through the activated coke When macromolecular organic matter and refractory organic matter are adsorbed and removed, the ratio of the qu...

Embodiment 2

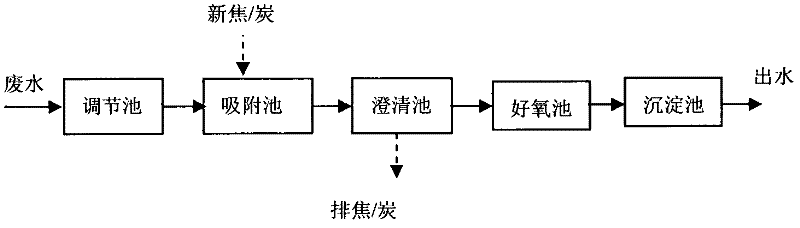

[0036] As an alternative embodiment of Example 1, in the clarification tank, a sedimentation tank or a mechanically accelerated clarification tank or a thickening tank can be used. The process of the coal chemical industry wastewater treatment process described in this embodiment is as follows: image 3 As shown, the specific steps are as follows:

[0037] ① Pass the coal chemical industry wastewater in the adjustment pool into the adsorption pool, in which active coke adsorption materials are continuously added, and the coal chemical industry wastewater is adsorbed through the activated coke, and the coal chemical industry wastewater flows through the activated coke At this time, macromolecular organic matter and refractory organic matter are adsorbed and removed. The ratio of the mass of the waste water to the mass of the active adsorption material added is 10:1-500:1, and 10:1 is selected in this embodiment.

[0038] ② The waste water absorbed by the activated coke is sep...

Embodiment 3

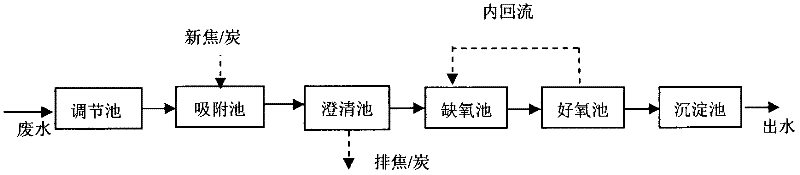

[0043] As an embodiment that can be changed in embodiment 1, the process of the coal chemical industry wastewater treatment process described in this embodiment is as follows Figure 4 As shown, the specific steps are as follows:

[0044] ① Pass the coal chemical industry wastewater in the adjustment pool into the adsorption pool, in which active coke adsorption materials are continuously added, and the coal chemical industry wastewater is adsorbed through the activated coke, and the coal chemical industry wastewater flows through the activated coke At this time, macromolecular organic matter and refractory organic matter are adsorbed and removed. , the ratio of the quality of the waste water to the mass of the active adsorption material added is 10:1-500:1, and 500:1 is selected in this embodiment.

[0045] ② The waste water absorbed by the active coke is separated from the active coke and water through the clarifier. In the clarifier, a sedimentation tank or a mechanically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com