Method for extracting raffinose from cottonseed wastewater

A technology of raffinose and cottonseed, which is applied in the direction of chemical instruments and methods, oligosaccharides, sugar derivatives, etc., can solve the problems of reduced solubility of raffinose, unsuitability for industrialization, and increased recycling costs, and facilitate large-scale industrial production and production The effect of cost reduction and avoiding re-drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

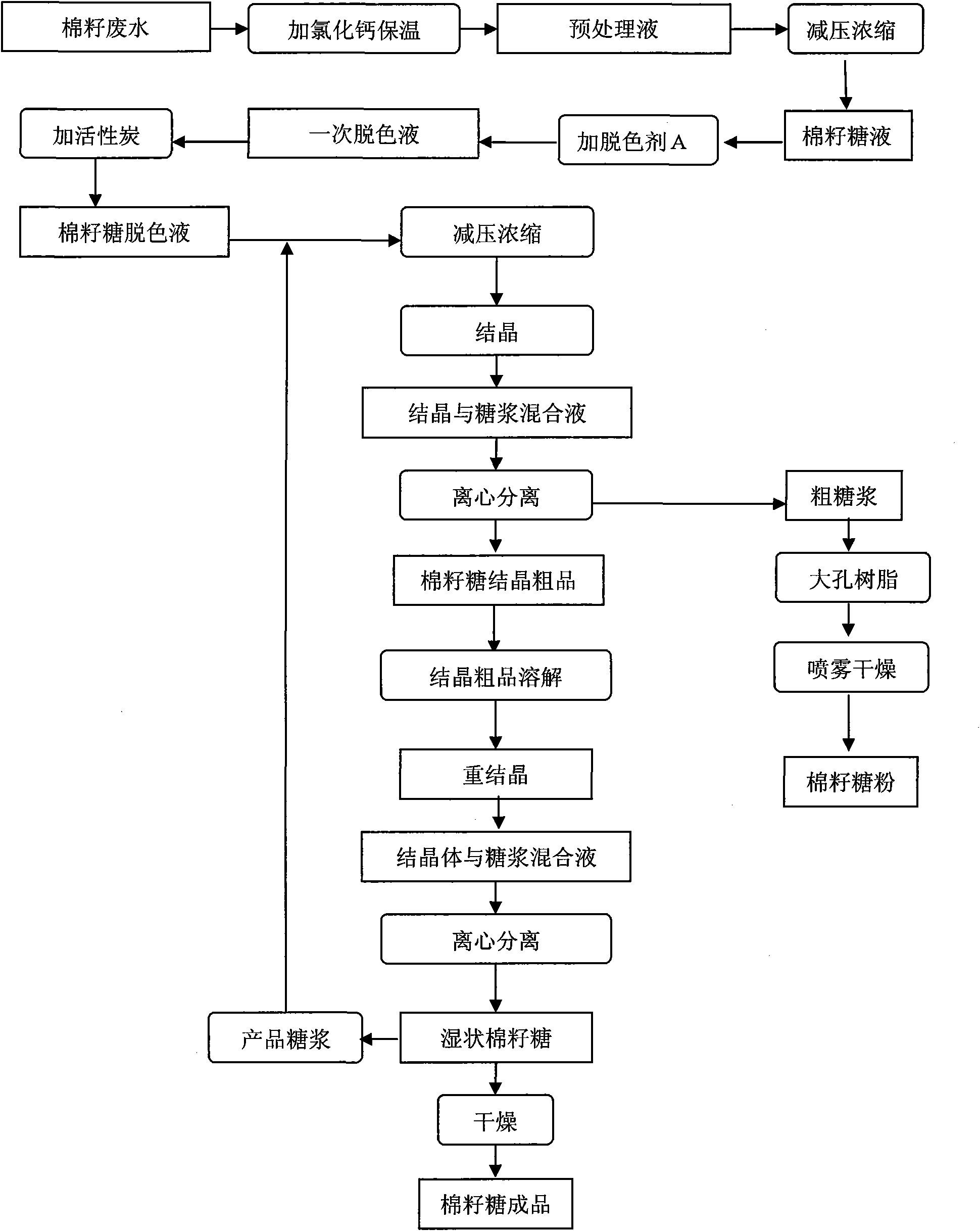

Image

Examples

Embodiment Construction

[0025] Hereinafter, the content of the invention will be described in detail through implementation examples, but the invention is not limited thereto.

[0026] (1) Take 200L of waste water, the measured solid content is 3.3%, heat it to about 75°C, adjust the pH value to 4.4 with hydrochloric acid, add 0.64Kg calcium chloride while stirring, keep this temperature for about 30min, then add 0.2 Kg diatomaceous earth, 178L of pretreatment solution was obtained after plate and frame filtration; the pretreatment solution was concentrated at a temperature of about 75°C at a vacuum of -0.07Mpa to obtain 16.4L of raffinose solution, and the measured solid concentration was 26.7%. .

[0027] (2) After adjusting the pH to 6.5 with calcium oxide, add polyaluminum, at this time the temperature is 64°C, after stirring for about 40 minutes, let it stand for 30 minutes, and centrifuge to obtain 15.1L of filtrate, heat the filtrate to 75°C, and use Adjust the pH value of the solution to 3.4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com