Ethylene-Propylene-Diene Monomer (DPDM) rubber composition

A technology of EPDM rubber and composition, which is applied in the direction of hoses, mechanical equipment, pipes/pipe joints/pipe fittings, etc., can solve problems such as not meeting the requirements for the use of radiator hoses, improve service life, avoid clogging, Effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

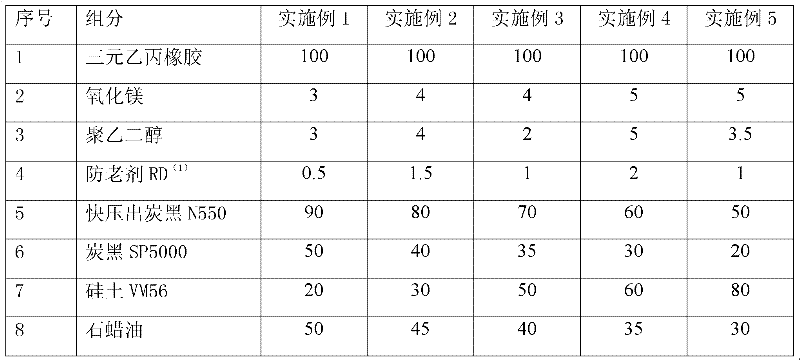

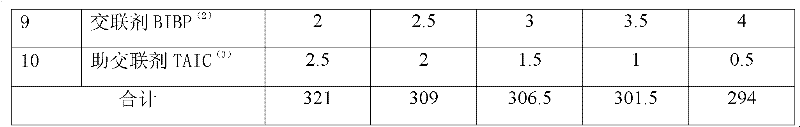

[0023] Each component of the EPDM composition is in parts by mass:

[0024]

[0025]

[0026] Note: (1) Antiaging agent RD: 2,2,4-trimethyl-1,2-dihydroquinoline;

[0027] (2) Crosslinking agent BIBP: 1,4-bis(tert-butylperoxyisopropyl)benzene;

[0028] (3) Auxiliary cross-linking agent TAIC: triallyl isocyanate

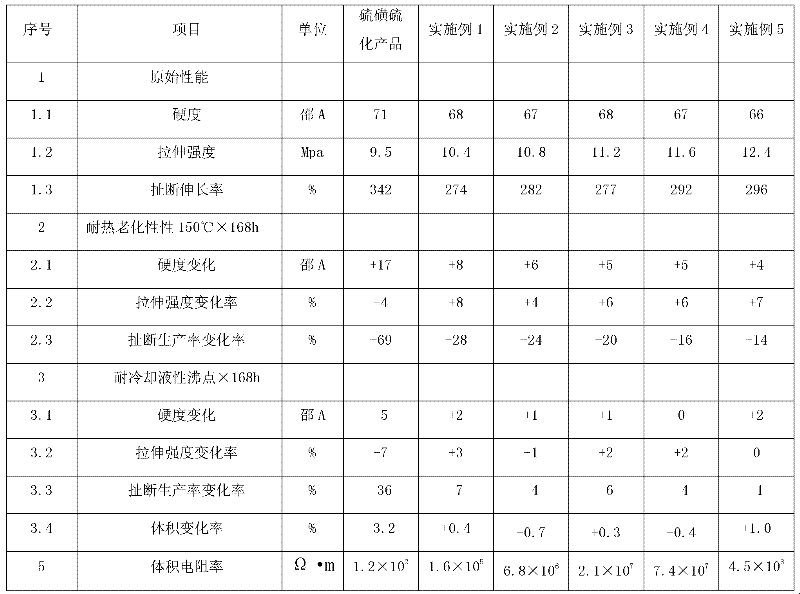

[0029] According to the raw materials in the formula of the implementation list, the film is made into a film for testing and testing. The performance comparison of the EPDM composition with high temperature resistance and electrochemical corrosion resistance and the sulfur vulcanized EPDM rubber is as follows:

[0030]

[0031] From the data in the above table, it can be concluded that the EPDM rubber composition with high temperature resistance and electrochemical corrosion resistance is not only better in high temperature aging resistance than sulfur vulcanized EPDM rubber, but also has better cooling liquid resistance and The electrical insulation is als...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com