Capsule type anti-corrosion device with pile shoe and anti-corrosion pile using same and construction method

A technology of anti-corrosion device and construction method, which is applied in sheet pile wall, foundation structure engineering, construction and other directions, can solve the problems that the bearing and deformation properties are difficult to meet the requirements, the anti-corrosion effect is not obvious, and the construction cost is high, and the improvement of materials and anti-corrosion technology can be achieved. , The effect of flexible production and manufacturing methods, reducing consumption and construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

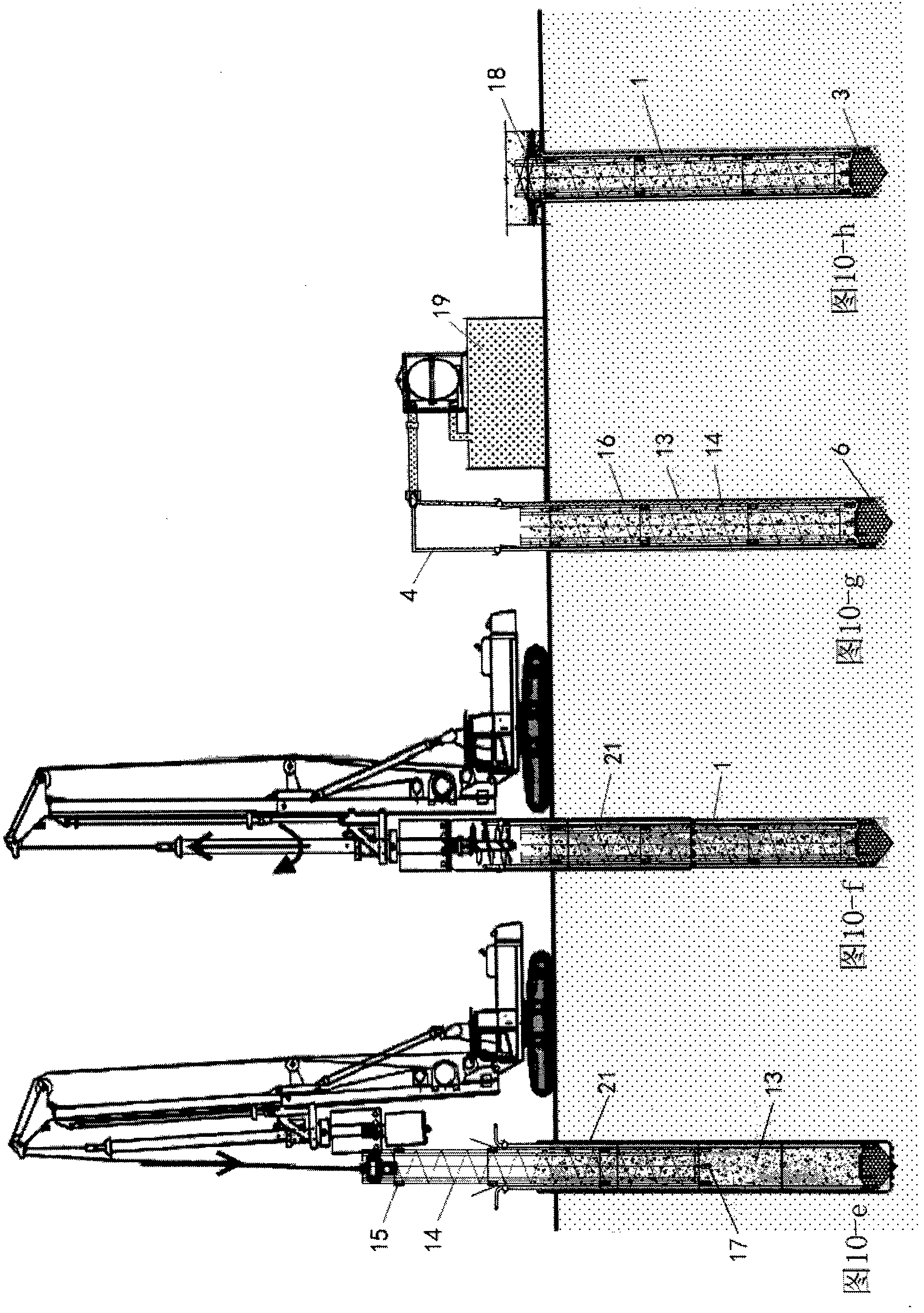

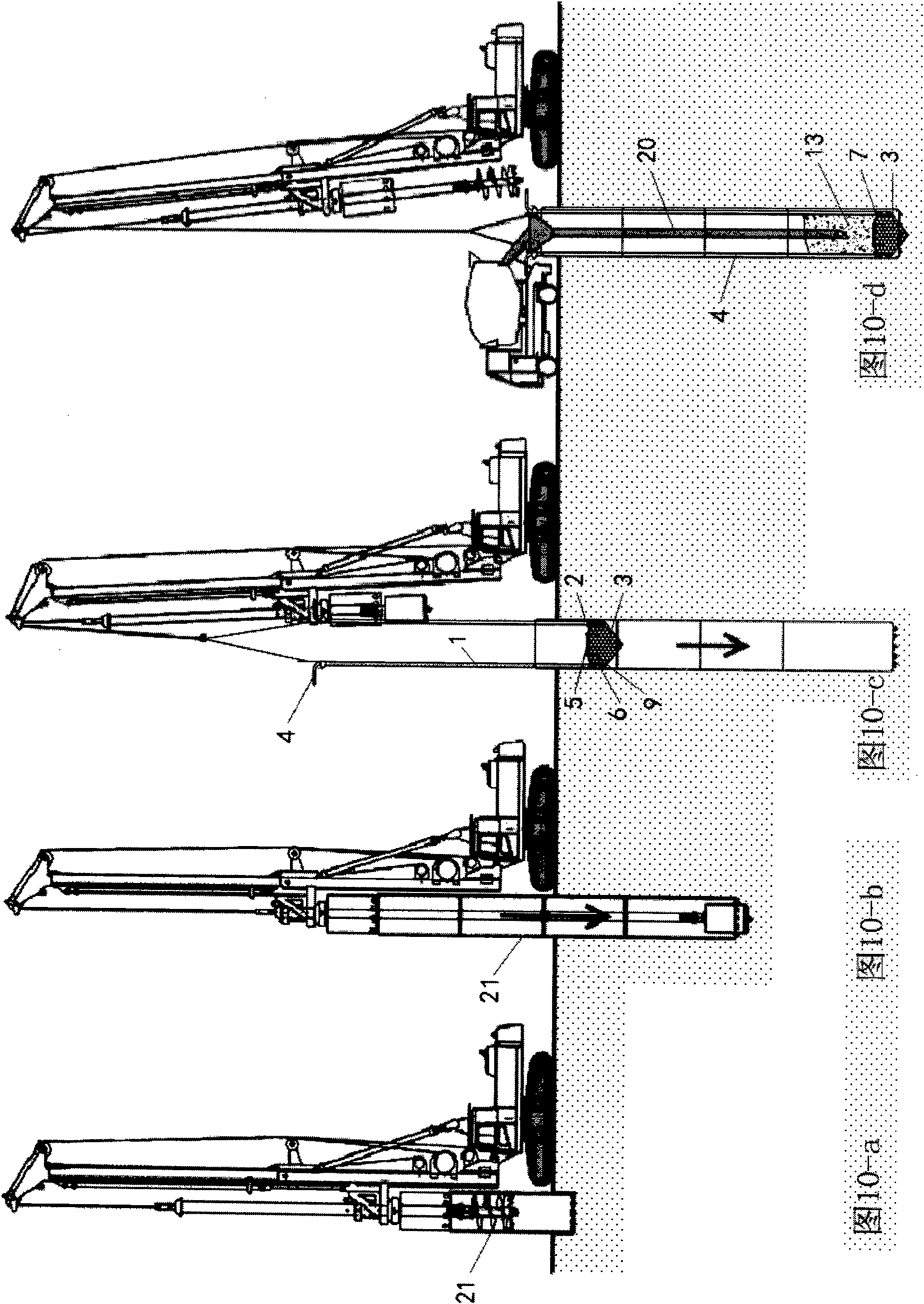

[0058] Referring to Fig. 10a-10h, the construction method of anticorrosion pile of the present invention, comprises the steps:

[0059] A. Utilize the full-casing drilling rig to drill a drill hole with a design depth at the pile position through the steel casing 21 and the drill bit inside the steel casing 21. The diameter of the hole is 600-1500mm;

[0060] B. Lift the drill pipe and drill bit out of the pile hole;

[0061] C. Insert the capsule type anti-corrosion device with spud can into the pile hole, and place the anti-corrosion spud can 3 at the preset position at the bottom of the pile hole;

[0062] D. Insert the concrete conduit 20 into the covering capsule body 1 of the capsule type anticorrosion device with spud cans in the pile hole, and continuously pour the expanded concrete 13 into the covering capsule body 1 through the concrete conduit 20, and pour the expanded concrete 13 The flow rate is 0.05~1.0m 3 / min, until the expansive concrete 13 in the cladding c...

Embodiment 2

[0068] Referring to Fig. 11a-11f, the construction method of anticorrosion pile of the present invention, comprises the steps:

[0069] A, drill the borehole of the design depth at the pile position, the specific method is to put the long drill frame high-pressure jet grouting drilling rig 22 in place, and use low-pressure jetting wall protection mud or cement slurry 24 or 24 in the surface casing 23 at the pile position. Qingshui 25 is drilled into the hole to the design depth;

[0070] B. Start the high-pressure water pump with a pump pressure of 20-40MPa and the low-pressure grouting pump with a pump pressure of 2-8MPa. At the same time, the drill pipe is lifted to the surface while spraying at a speed of 8-25r / min and speed-up: 8-25cm / min. ;

[0071] C. Install the capsule type anti-corrosion device with spud shoes and the vibration impact hammer 26 in place, and gradually vibrate the capsule type anti-corrosion device with spud shoes in the pile hole slurry under the vib...

Embodiment 3

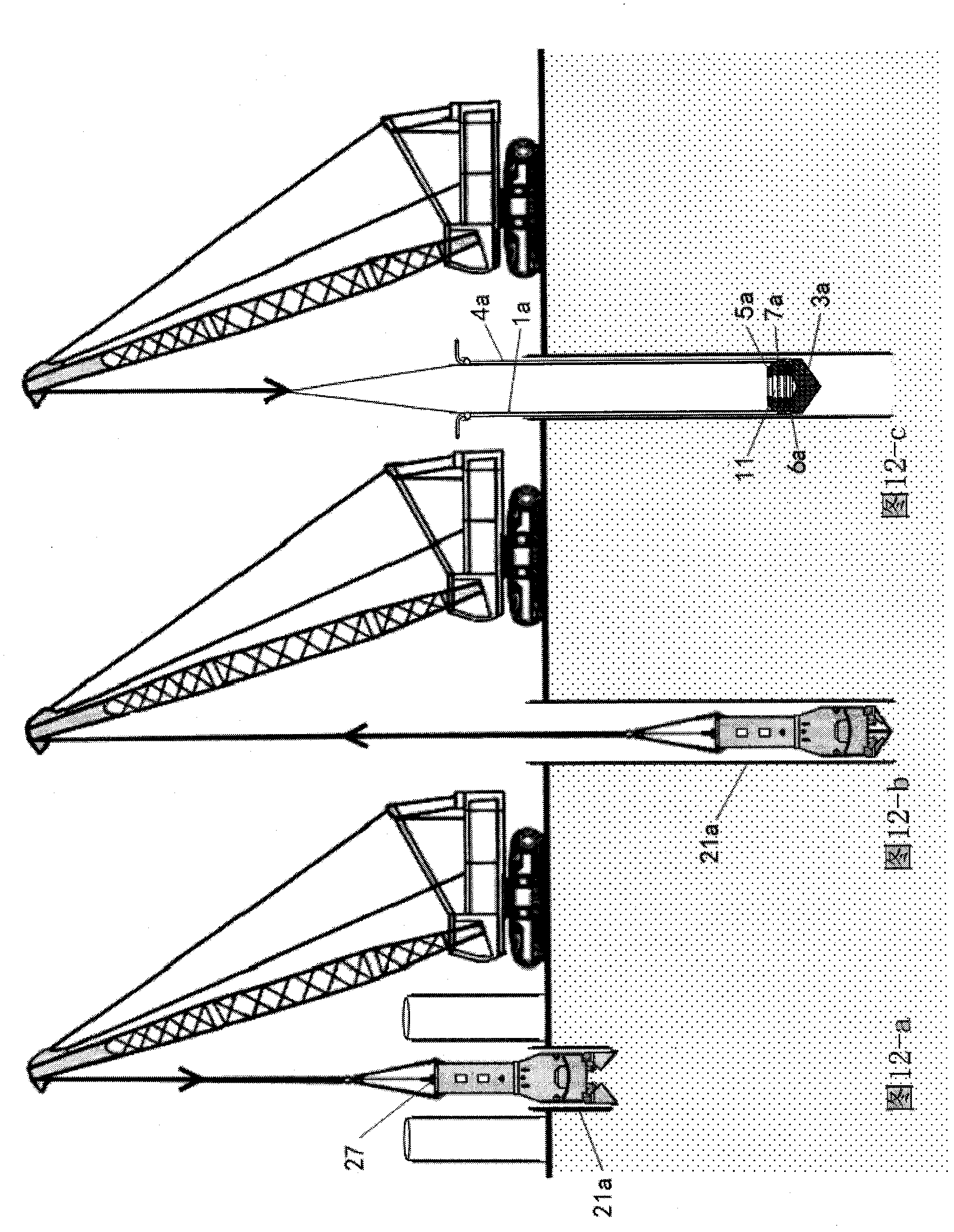

[0078] Referring to Fig. 12a-12g, the construction method of anticorrosion pile of the present invention comprises the following steps:

[0079] A, prepare the crane, multi-section steel casing 21 and grab bucket 27, use the grab bucket 27 to dig out the soil at the pile position in the first section steel casing 21, and gradually discharge the soil in the steel casing, the steel pipe injection The slurry sinks to slightly higher than the ground surface, then hangs the second section of steel casing 21, connects the bottom end of the second section of steel pipe with the top of the first section of steel pipe, after completing the connection, continue to use the grab bucket 27 to grab the The corrosive soil in the deeper second section of the steel pipe is discharged from the pile hole and circulates like this until the steel casing 21 sinks into the design pile length depth;

[0080] B. Put the grab bucket 27 out of the pile hole;

[0081] C. Insert the capsule type anti-cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com