Multi-level fully-closed reinforcement technology of exposed fault zone of excavated side slope

A multi-level, fully enclosed technology, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of long construction time of anchor cables, poor fault properties, limited depth and scope of reinforcement, etc., to improve the integrity and strength. Prevent collapse and damage, solve the effect of insufficient anchoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further introduced below in conjunction with specific embodiments of the present invention.

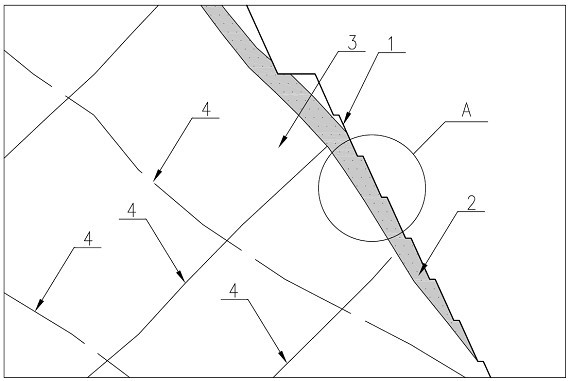

[0038] like figure 1 As shown, in a high and steep rocky slope, the fault fracture zone (2) is exposed after the slope is excavated, and there are also unloading fractures along the slope and anti-dip layer fractures (4) in the slope. The fault fracture zone (2) is exposed along the slope with a width of about 6-10m, and its components are cataclastite, mylonite, breccia and a small amount of fault gouge. After the slope excavation contour line (1) is formed, the stability of the slope is poor, and sliding collapse along the fault to the outside of the slope may occur.

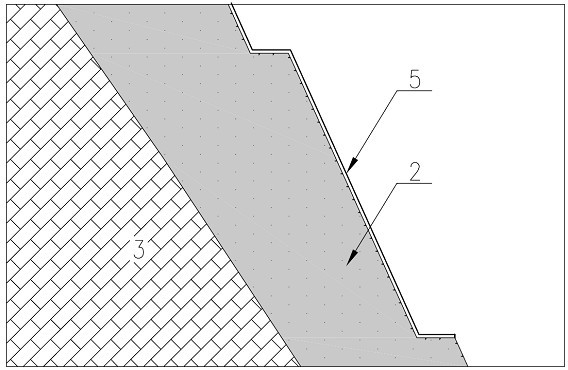

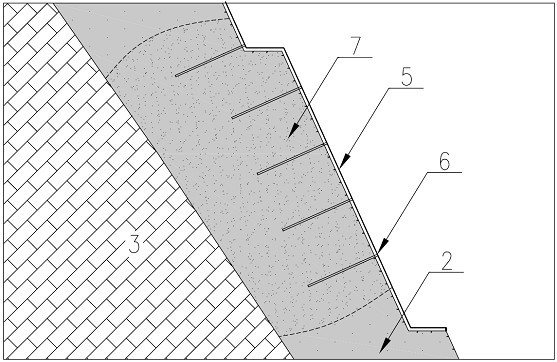

[0039] For the exposed area of the slope fault fracture zone (2), reinforcement and treatment will be carried out in four stages:

[0040] The first stage (such as figure 2 Shown): After the slope is excavated, immediately spray a layer of plain concrete (5) on the exposed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com