Bipolar plate capable of doing work on double surfaces and high-energy battery thereof

A bipolar plate, one side of the substrate technology, applied in the direction of secondary batteries, lead-acid batteries, battery components, etc., can solve problems such as sulfation of the electrode surface, corrosion of the grid, and large room for battery capacity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

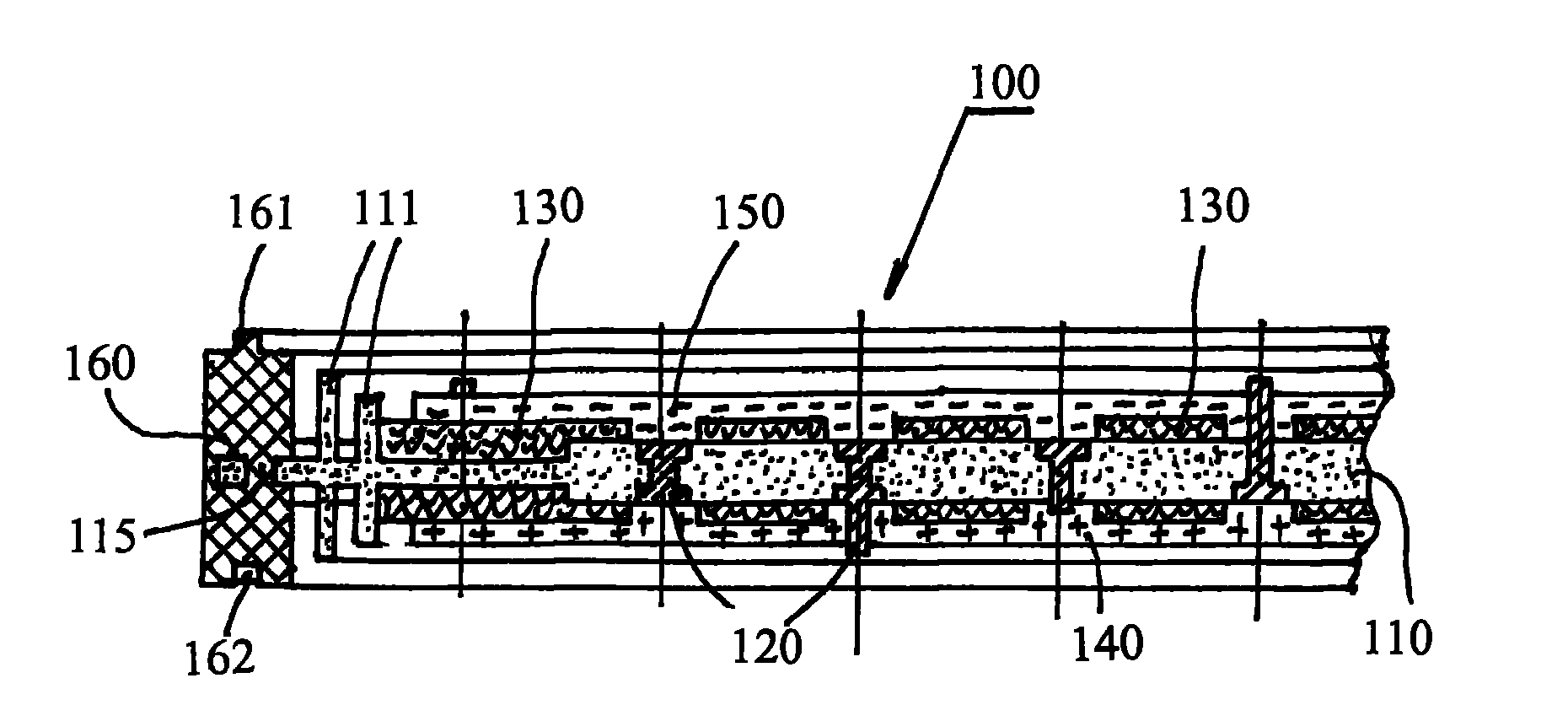

[0053] Example 1: Bipolar plate (100).

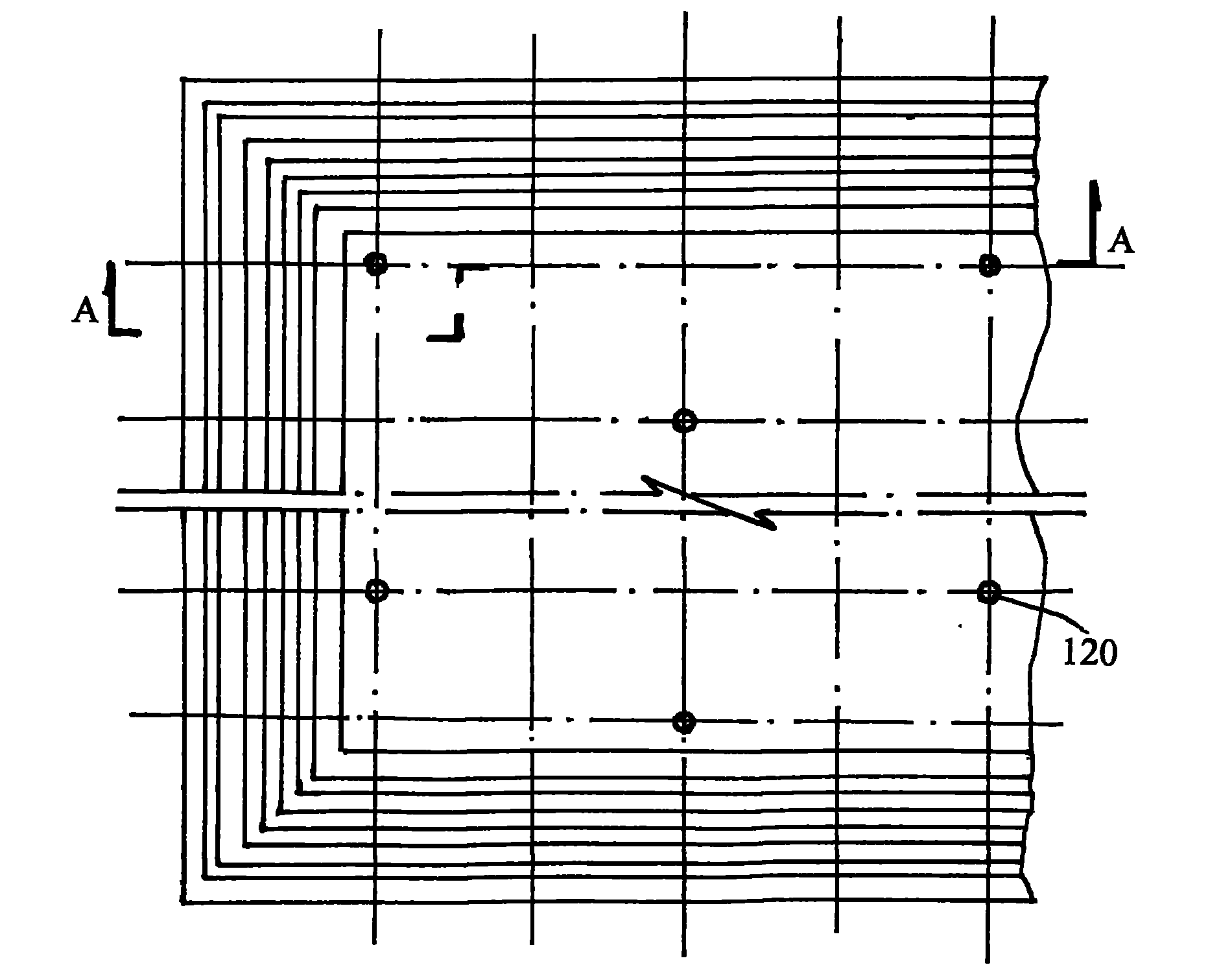

[0054] see picture 1, figure 2 , the bipolar plate (100) consists of a substrate (110), a conductive needle (120), a felt film layer (130), a positive electrode active material layer (140), a negative electrode active material layer (150), a retaining ring (111) and a frame ( 160) composition. according to Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 Shown, preferred pure lead is made into the conductive pin (120) of different shapes, or makes the conductive pin (120) of one or more shapes in them, then the conductive pin (120) is pressed Figure 15A , Figure 15B , Figure 15C , Figure 15D , Figure 15E The upper coating film (125) is shown, and the coating film (125) is preferably made of a hydrophobic material, and more preferably made of the same fluoropolymer as that of the substrate (110). Put the conductive needles (120) coated with the coating film (125) into the...

Embodiment 2

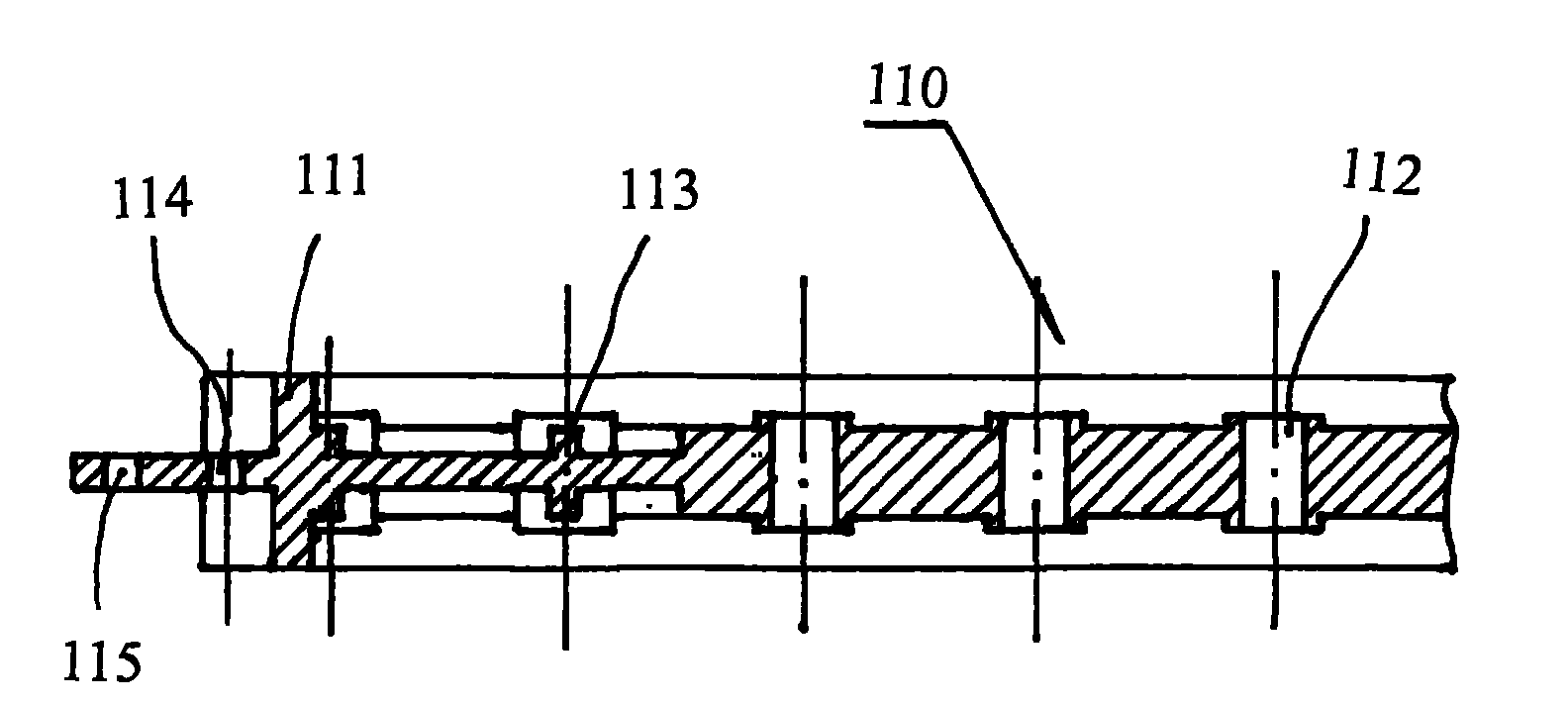

[0055] Embodiment 2: The second form of the substrate (110).

[0056] See Figure 3, Figure 4 , the base plate (110) is provided with: a retaining ring (111), a chamfer (116) is arranged on the side of the retaining ring (111), and a vent hole (114) is arranged on the chamfer (116), the vent hole (114) The air chambers of each battery unit are connected to form a common air chamber, so that the pressure difference of each battery unit is 0, and the air hole (114) can also be used as the inlet and outlet of the electrolyte; The hole platform (112) used for the needle (120), the conductive needle (120) coated with the coating film (125) can be inserted into the hole platform (112) and fixed on it, the fixing method can be welding, heat welding, adhesive bonding In order to enhance the strength of the substrate (110) and produce a large-scale battery, a large number of reinforcing ribs (113) are arranged on the substrate (110), and the reinforcing ribs (113) and the hole platfor...

Embodiment 3

[0057] Embodiment 3: Electrode modification and anticorrosion treatment of the conductive needle (120).

[0058] In a lead-acid battery, if the conductive pins (120) are made of titanium, stainless steel, or non-preferred metal materials, electrode modification is preferably performed. The formed conductive needle (120) is coated with an inorganic conductive material such as conductive ceramics, conductive glass or conductive oxide as a whole or part of the contact electrolyte, and the preferred material is (SnO 2 +Sb 2 o 3 ), (SnO 2 +SbO×+IrO 3 ), Ti 3 SiC 2 、Ti 3 AiC 2 、TiB 2 , TiC; and then coat a layer of organic conductive coating on the outside of the inorganic layer by means of electrode modification. The preferred material is polyphenylamine PAn conductive high polymer or PAn composite conductive plastic with other materials. This modification method can also be non-preferably coated with only one inorganic conductive layer or only coated with one organic cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com