Method for purifying and refining lamivudine and emtricitabine

A refining method and technology of emtricitabine, applied in organic chemistry and other directions, can solve problems such as increasing impurities and causing ear poisoning, and achieve the effects of reducing pollution, improving product quality, and safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

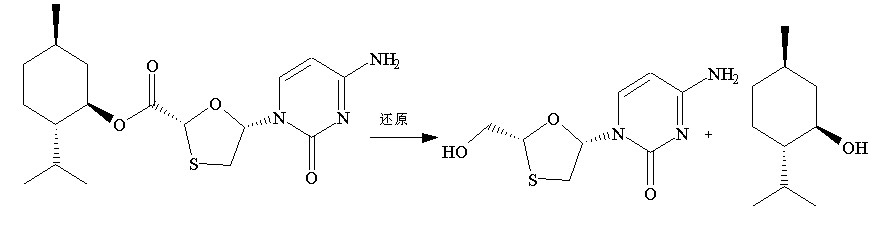

[0029] Embodiment 1: see figure 1 , a method for purifying and refining lamivudine, the steps are as follows:

[0030] 1. Add 100ml of ethanol and 25ml of water to reactor A, then add 8.6 grams of dipotassium hydrogen phosphate and stir to dissolve; then add 10 grams of (2R, 5S)-5-(cytosine-1-yl)-1,3-oxo Thiolane-2-carboxylic acid-L-menthyl ester was stirred for 1 hour and the temperature was started to drop. Add 10-15 ml of water, 2.1 grams of sodium borohydride and 0.05-0.1 gram of sodium hydroxide into reactor B, stir to dissolve, and cool down for later use;

[0031] 2. When the temperature of reactor A is 15°C, start adding the solution in reactor B dropwise, and control the reaction temperature to ≤25°C for about 3-5 hours;

[0032] 3. Keep the temperature at 15-25°C for reaction, take a sample to measure (2R,5S)-5-(cytosine-1-yl)-1,3-oxathiolane-2-carboxylic acid-L after adding 1h -Residue of menthyl ester, the residual amount of 0.5% is the reaction end point;

[0...

Embodiment 2

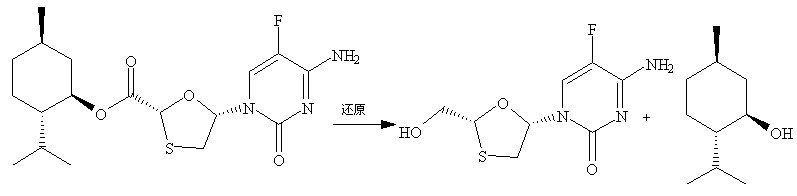

[0046] Example 2: see figure 2 , a method for purifying and refining emtricitabine, the steps are as follows

[0047] 1. Add 100ml of ethanol and 25ml of water to reactor A, then add 8.6 grams of dipotassium hydrogen phosphate and stir to dissolve; then add 10 grams of (2R, 5S)-5-(5'-fluoro-cytosine-1-yl)- 1,3-Oxathiolane-2-carboxylic acid-L-menthyl ester was stirred for 1 hour and the temperature was started to drop. Add 10-15 ml of water, 2.1 grams of sodium borohydride and 0.05-0.1 gram of sodium hydroxide into reactor B, stir to dissolve, and cool down for later use;

[0048] 2. When the temperature of reactor A is 15°C, start adding the solution in reactor B dropwise, and control the reaction temperature to ≤25°C for about 3-5 hours;

[0049] 3. Keep the temperature at 15-25°C for reaction, and take a sample to measure (2R,5S)-5-(5'-fluoro-cytosine-1-yl)-1,3-oxathiolane-2 after 1 hour of addition -Carboxylic acid-L-menthyl ester residue, 0.5% residue is the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com