Method for preparing chemically mechanical polishing (CMP) solution for KTiOPO4 crystal

A technology of potassium titanyl phosphate and polishing liquid, which is applied in the direction of polishing compositions containing abrasives, etc., which can solve the problems of organic matter, metal ions, large particle harmful pollution, reduced device yield, and increased cost, achieving high speed and high efficiency. Smooth and low-damage polishing, cost reduction, and less pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: preparation 4000gKTP crystal polishing liquid

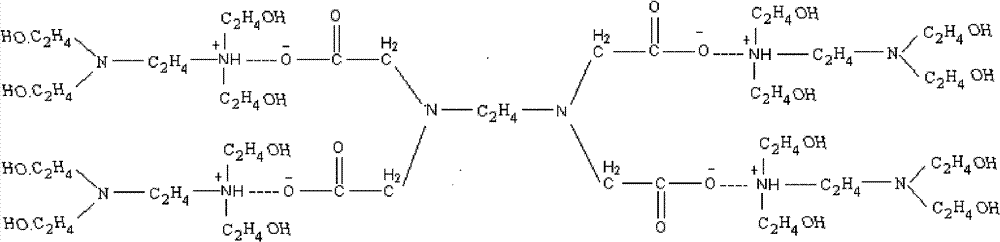

[0029] Under negative pressure stirring, take 160g of amine base, weigh 40gKOH and dilute with 200g of ultra-pure deionized water above 18MΩ, 40g of FA / O active agent and 40g of FA / O chelating agent in order, and then under negative pressure. 15-25nm nano-SiO 2 800g of sol was inhaled, and finally 2720g of deionized water was inhaled while stirring. After stirring evenly under the vortex state, 4000g of KTP crystal polishing liquid is obtained, which can be filled after stirring evenly.

Embodiment 2

[0030] Embodiment 2: preparation 4000gKTP crystal polishing fluid

[0031] Under negative pressure stirring, take 80g of amine base, weigh 20g of KOH, dilute with 100g of ultra-pure deionized water above 18MΩ, inhale 10g of FA / O active agent and 10g of FA / O chelating agent in sequence, and then inhale the particle size under negative pressure. 15-25nm nano-SiO 2 3600g of sol was inhaled, and finally 180g of deionized water was inhaled while stirring. After stirring evenly under the vortex state, 4000g of KTP crystal polishing liquid is obtained, which can be filled after stirring evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com