Cobalt-based cobalt-boron intermediate alloy and preparation method thereof

A master alloy, cobalt-based cobalt-boron technology, which is applied to non-ferrous-based special cobalt-based cobalt-boron master alloys, cobalt-based cobalt-boron master alloys and their preparation fields, to achieve the effects of saving electric energy, large pollution, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

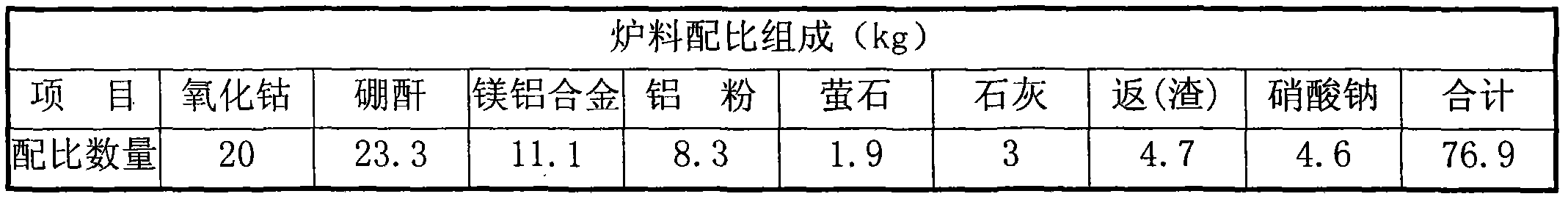

[0031] Embodiment 1: The product quantity is 20kg level.

[0032] (1) Testing of raw materials used in smelting cobalt-boron master alloys:

[0033] a. Cobalt oxide Co 2 o 3 99.852%, Ni<0.01%, Si<0.016%, Al 0.014%, Fe 0.04%; C 0.01%, S 0.057%.

[0034] b. Boric anhydride: containing B 2 o 3 98.5%, sulfate 0.02%, heavy metal 0.005%, silicon and alkali metal 0.1%.

[0035] c. Aluminum particles: Al 99%, Fe 0.3%, Si 0.02%.

[0036] d. Aluminum-magnesium alloy: Al 39.65%, Mg 60.28%, Si 0.01%, S 0.014%, Fe 0.06%, C 0.009%.

[0037] e. Lime: CaO 81.49%, SiO 2 10%.

[0038] f. Fluorite: CaF 2 99.13%, SiO 2 0.62%, P 0.012%.

[0039] g. Sodium nitrate: NaNO 3 98.5%.

[0040] (2) Ingredients preset:

[0041] a. Refined product: Contains 80% Co, 18% B, and the rest is impurities.

[0042] b. The dosage of lime is 13% of the total amount of boric anhydride.

[0043] c. The dosage of fluorite is 8% of the total amount of boric anhydride.

[0044] d. The reducing agent is a...

Embodiment 2

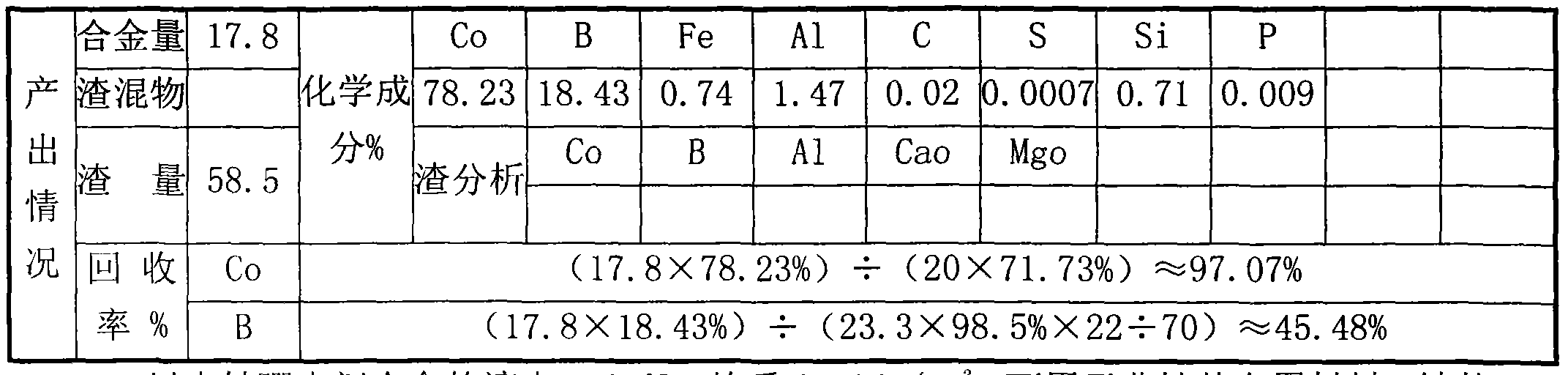

[0060] Embodiment 2, product quantity is 50kg level

[0061] (1) Detection of main raw materials and auxiliary materials used in smelting cobalt-based cobalt-boron master alloys:

[0062] a. Cobalt oxide Co 2 o 3 99.767%, Ni<0.006%, Si<0.09%, Al 0.005%, Fe 0.10%; C 0.03%, S 0.002%.

[0063] b, boric anhydride (B 2 o 3 ): Contains B 2 o 3 98.5%, sulfate 0.02%, heavy metal 0.005%, silicon and alkali metal 0.10%.

[0064] c. Aluminum particles: Al 99%, Fe 0.3%, Si 0.02%.

[0065] d. Aluminum-magnesium alloy: Al 59.93%, Mg 39.84%, Si 0.03%, S 0.014%, Fe 0.31%, C 0.009%.

[0066] e. Lime: CaO 92%, SiO 2 5.0%.

[0067] f. Fluorite: CaF 2 99.13%, SiO 2 0.62%, P 0.012%.

[0068] g. Sodium nitrate: NaNO 3 98.5%.

[0069] (2) Ingredients preset:

[0070] a. Refining cobalt-boron master alloy products: containing 81% Co, 16% B, and the balance is impurities.

[0071] b. The dosage of lime: CaO accounts for 12% of the total amount of boric anhydride.

[0072] c. Fluorite...

Embodiment 3

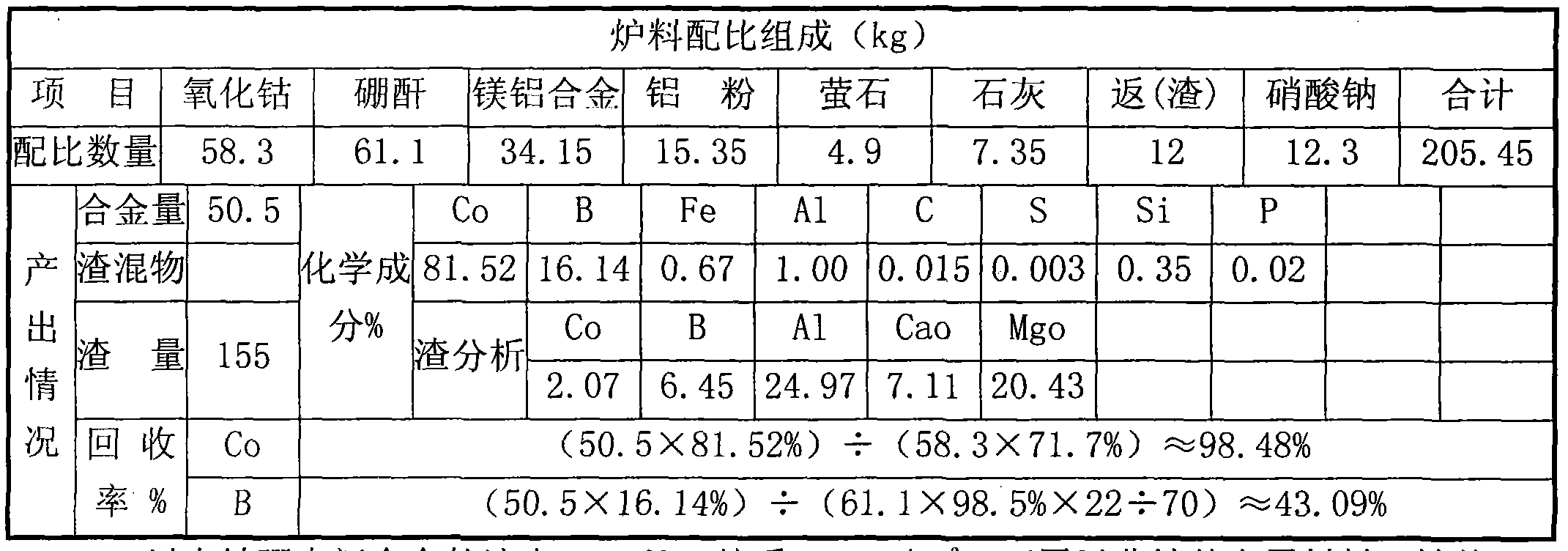

[0089] Embodiment 3, product quantity is 70kg level

[0090] (1) Detection of main raw materials and auxiliary materials used in smelting cobalt-based cobalt-boron master alloys:

[0091] a. Cobalt oxide Co 2 o 3 99.836%, Ni<0.01%, Si<0.016%, Al 0.014%, Fe 0.048%; C 0.019%, S 0.057%.

[0092] b, boric anhydride (B 2 o 3 ): Contains B 2 o 3 98.5%, sulfate 0.02%, heavy metal 0.005%, silicon and alkali metal 0.10%.

[0093] c. Aluminum particles: Al 99%, Fe 0.3%, Si 0.02%.

[0094] d. Aluminum-magnesium alloy: Al 39.65%, Mg 60.28%, Si 0.01%, S 0.014%, Fe 0.06%, C 0.009%.

[0095] e. Lime: CaO 81.49%, SiO 2 10%.

[0096] f. Fluorite: Contains CaF 2 99.13%, SiO 2 0.62%, P 0.012%.

[0097] g. Sodium nitrate: containing NaNO 3 98.5%.

[0098] (2) Ingredients preset:

[0099] a. Refining cobalt-boron master alloy products: the product contains 80% Co, 19% B, and the balance is impurities.

[0100] b. The dosage of lime: CaO accounts for 13% of the total amount of bori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com