Online preparing system and method for electrochemical grinding micro tool for line electrode

A technology for preparing a system and a wire electrode, which is applied in the field of micro-electrochemical processing, and achieves the effects of economical method, strong processing localization ability, and good process compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

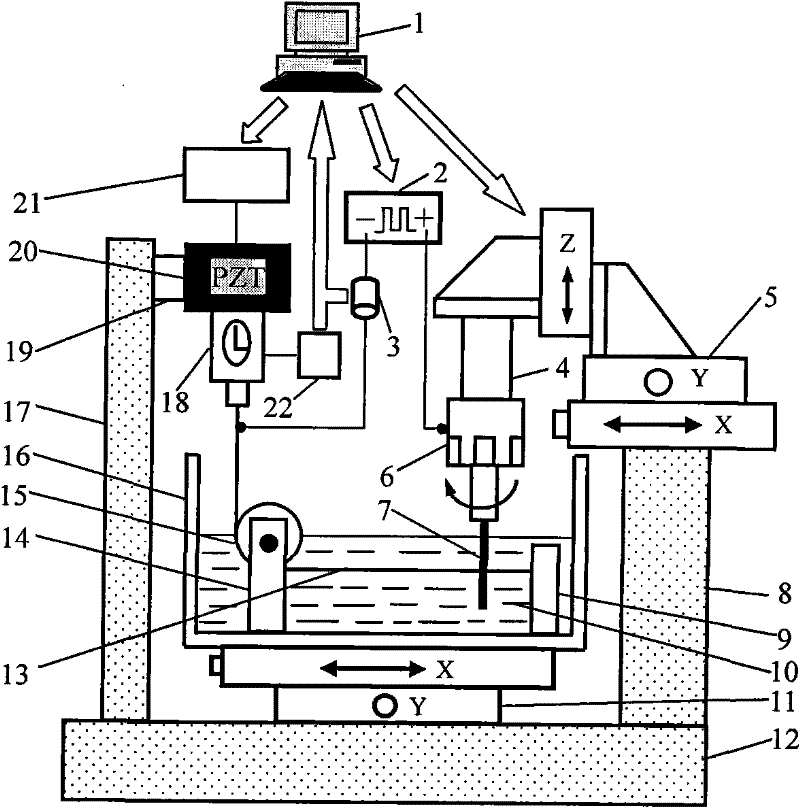

[0025] according to figure 1 Shown, the wire electrode electrochemical grinding micro tool online preparation device of the present invention consists of the following parts:

[0026] (1) Including machine tool table 12, machine tool vertical beam 8, column 17, piezoelectric ceramic displacement axis 20, piezoelectric servo controller 21, three-axis motion platform 5, XY two-dimensional numerical control workbench 11, numerical control rotary spindle 4, Computer 1 and other CNC machine tools that can realize three-degree-of-freedom movement;

[0027] (2) The electrolyte tank 16 is installed on the XY two-dimensional numerical control workbench 11 , and the electrode fixture 9 , bracket 14 , guide wheel 15 and microscale wire electrode 13 are fixed in the electrolyte tank 16 . The electrolyte solution 10 is filled with the electrolyte solution tank 16, submerging the horizontal part of the microscale wire electrode 13;

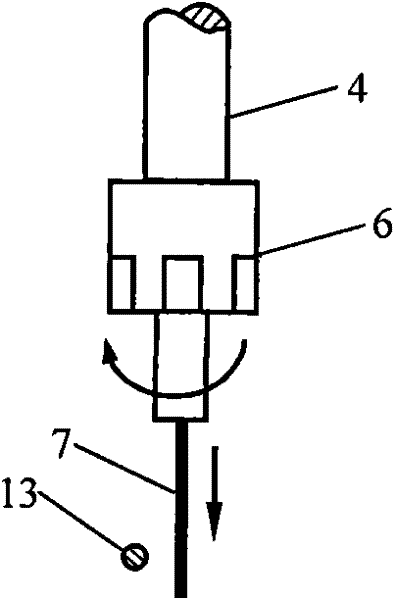

[0028] (3) One end of the micro-scale wire electrode 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com