Dielectrophoresis demulsification mechanism-based novel crude oil electric dehydration and desalination method and equipment

A technology of electrical dehydration and dielectrophoresis, which is applied in the direction of using electricity/magnetic dehydration/demulsification, separation of liquids by electricity, separation of immiscible liquids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

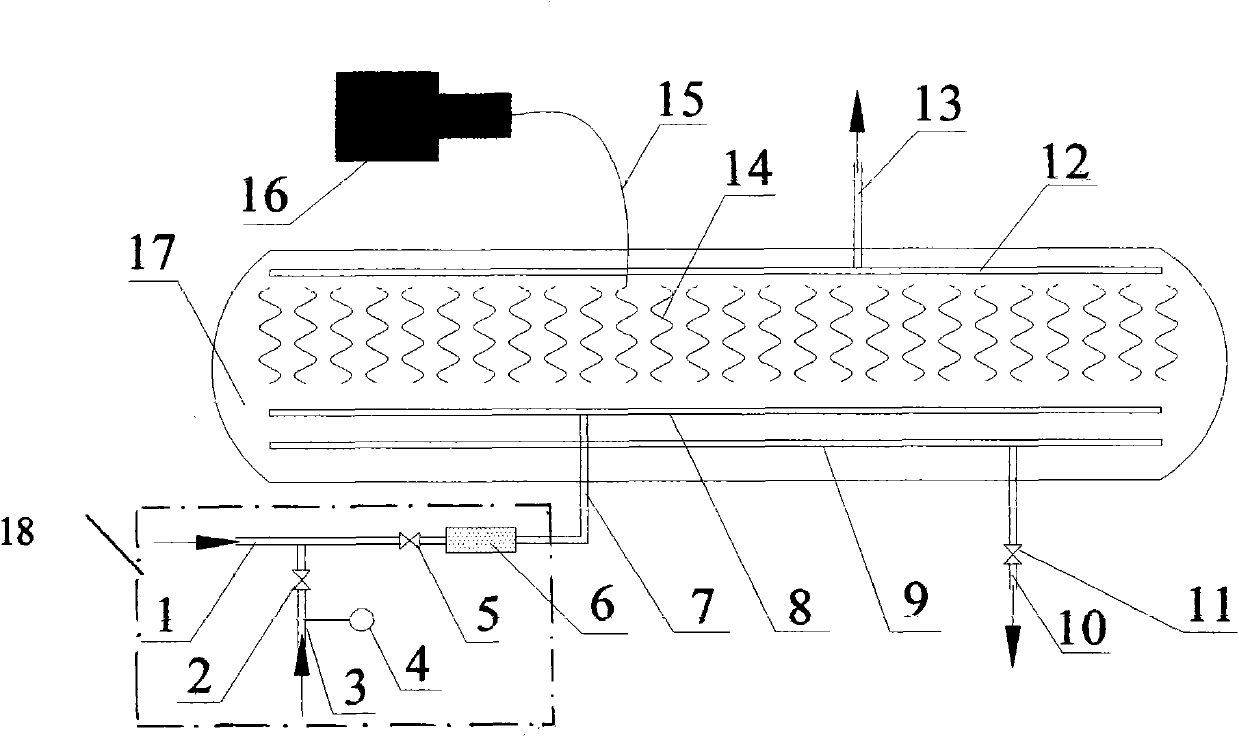

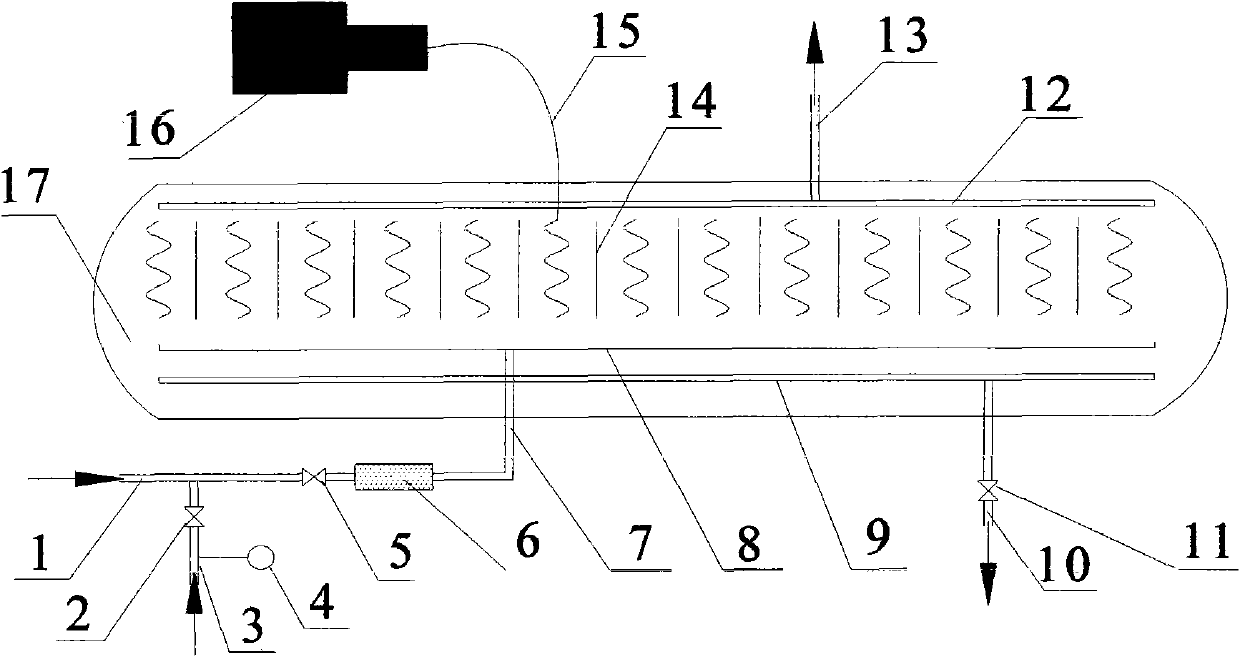

[0021] Further detailed description will be given below in conjunction with the accompanying drawings.

[0022] Depend on figure 1 It can be seen that the equipment of the present invention mainly includes an inlet assembly 18, a tank body 17 and an electrode assembly 14, wherein: the inlet assembly 18 is composed of a crude oil inlet 1, a fresh water inlet 3, a flow meter 4, a static mixer 6, valves 2, 5, etc.; The tank body 17 is provided with an inlet pipe 7 connected to the inlet assembly 18, a distributor 8, a water outlet pipe 9, a water outlet 10, and a valve, and an oil outlet 13 is arranged on the back of the tank body 17; a high-voltage insulated wire 15 The high-voltage explosion-proof transformer 16 is connected to the electrode assembly through the shell of the tank body 17; the distributor 8 is a steel plate with round or square holes.

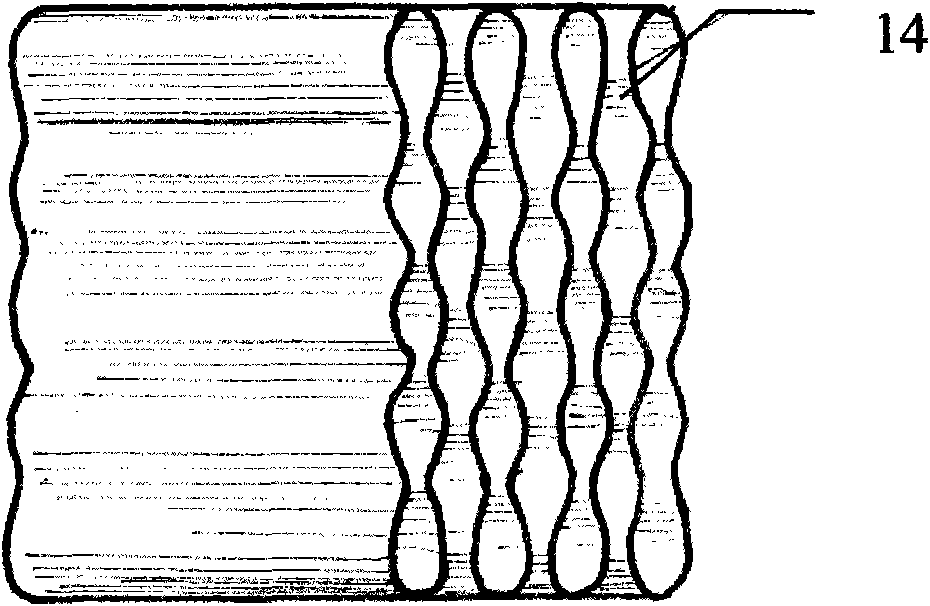

[0023] Depend on figure 2 It is shown that the electrode detail 14 is corrugated, and the corrugated electrodes 14 are verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com