Method for rapidly accumulating micro-algae intracellular grease

A microalgae and oil technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of no large-scale application value, inability to scale up, inability to achieve aseptic culture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] Add the following heterotrophic medium and tap water to 25 L in a 50 L bioreactor and then sterilize it. When the temperature drops to 30° C., add Chlorella pyrenoidosa according to 12% of the working volume to start heterotrophic culture.

[0104] Heterotrophic culture conditions: the temperature is 30°C, the initial speed is 150r / min, the air flow is 1vvm, the pH is less than 8.0, and the dissolved oxygen is controlled to be more than 15% by adjusting the speed during the cultivation process.

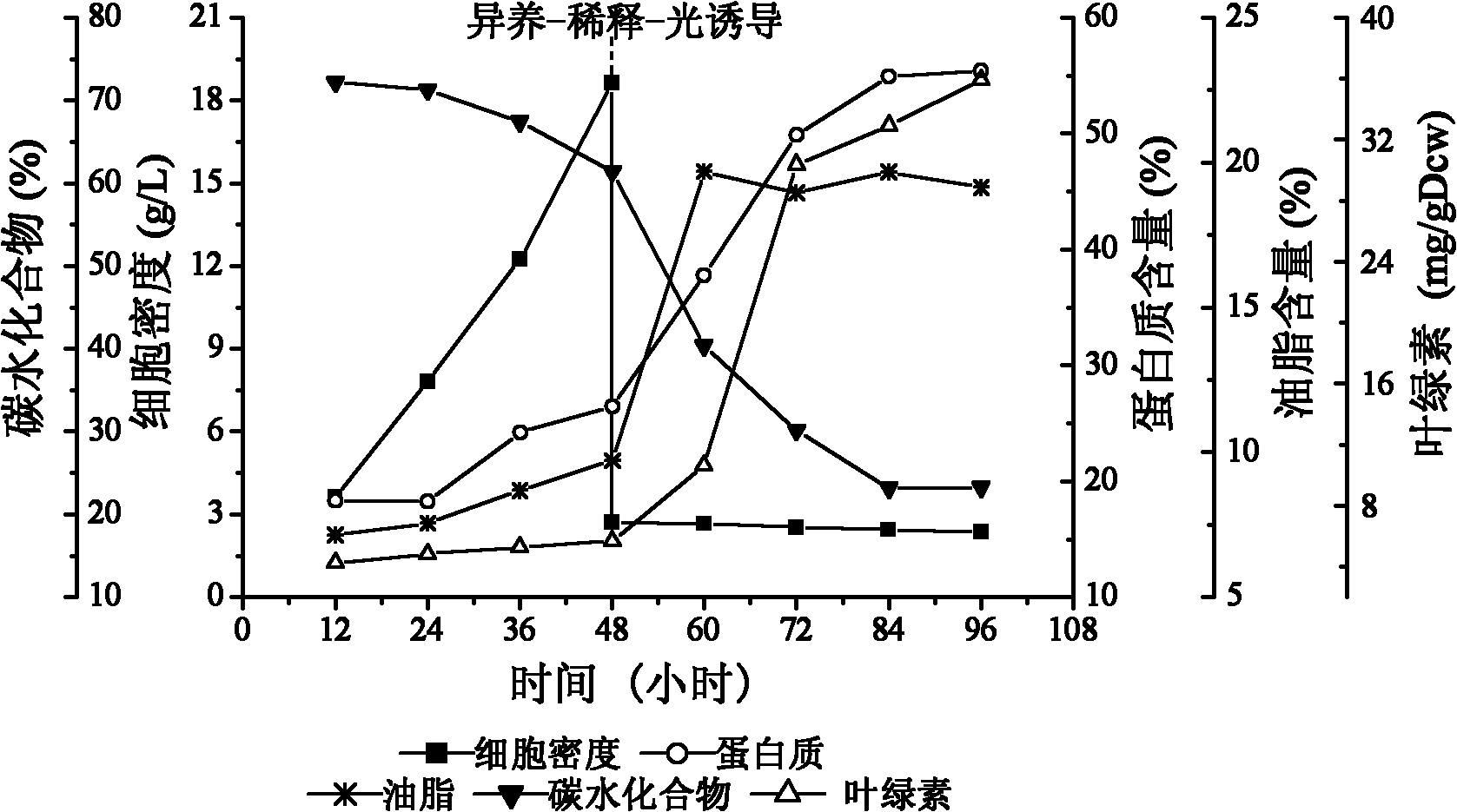

[0105] Dilute the high-density algae liquid that has run out of glucose during the heterotrophic culture to about 2.70g / L, add the following light-induced medium, and transfer it to a 3L flat-plate photoreactor for light-induced culture at a temperature of 30°C. Strong 8000lx, air flow is 1vvm. After light-induced culture for 12 hours, the cell density decreased from 2.70g / L to 2.65g / L, and the oil content increased from 9.70% to 19.70% (see figure 1 ).

[0106] Heterotrophic...

Embodiment 2

[0117] Add heterotrophic medium and tap water to 2.5T in a 5T fermenter and then sterilize it. When the temperature drops to 30°C, use a 500L fermenter as a seed tank to cultivate Chlorella vulgaris. The level of dissolved oxygen in the liquid is used to adjust the tank pressure, ventilation and stirring speed, maintain sufficient oxygen content in the culture liquid, and ensure the rapid growth of algae cells.

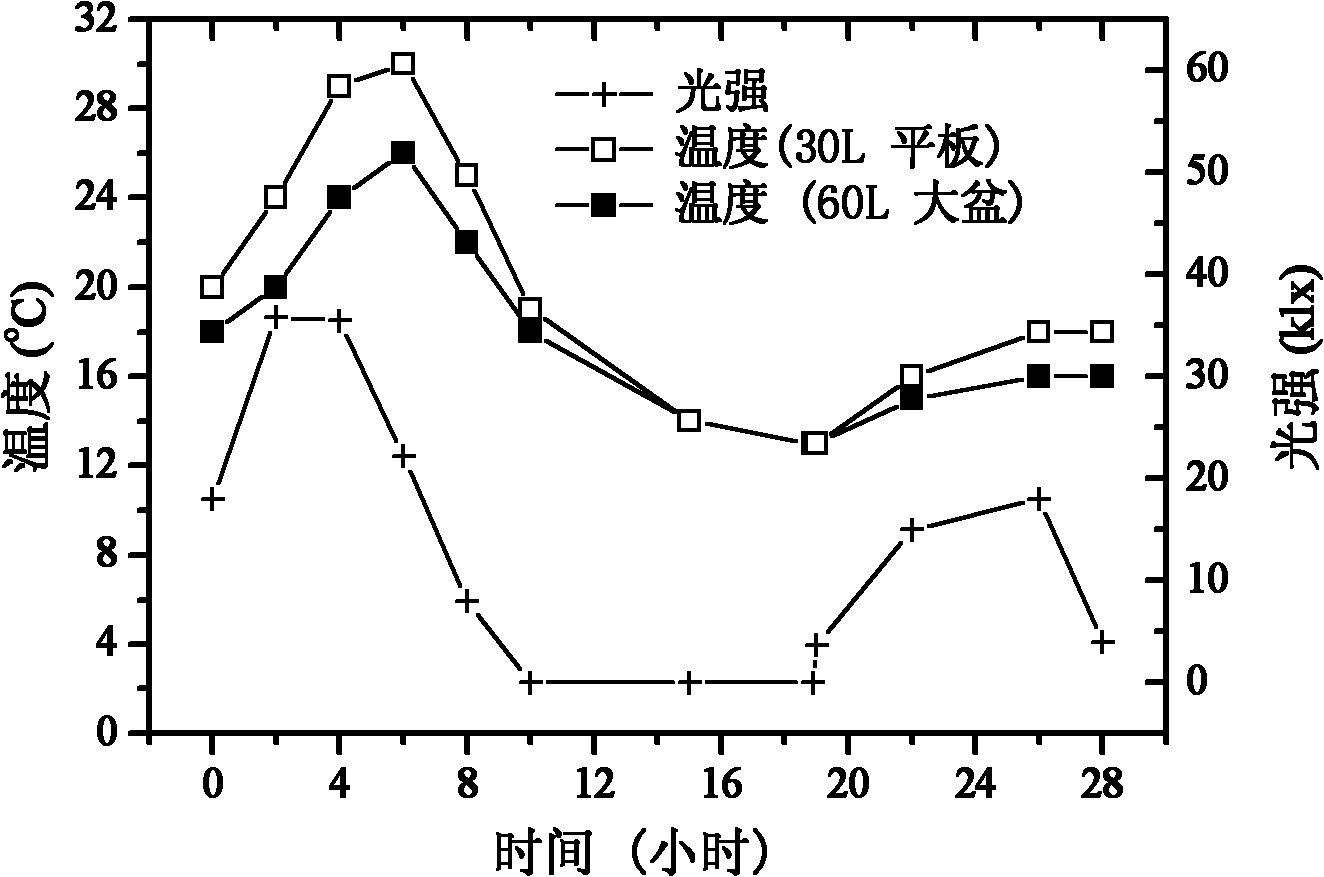

[0118] After diluting the high-density algae liquid that had run out of glucose in the previous fed-batch heterotrophic culture process, it was transferred to a 30L flat-plate photoreactor and a 60L bubbling large pot for light-induced culture outdoors. Light-induced culture conditions: natural temperature, temperature at 13-30°C, natural light, light intensity at 0-36klx (see figure 2 ), the air flow rate is 1vvm. After 8 hours of light-induced culture, the algal cell density in the 30L plate reactor decreased from 1.60g / L to 1.46g / L, and the oil content increased ...

Embodiment 3

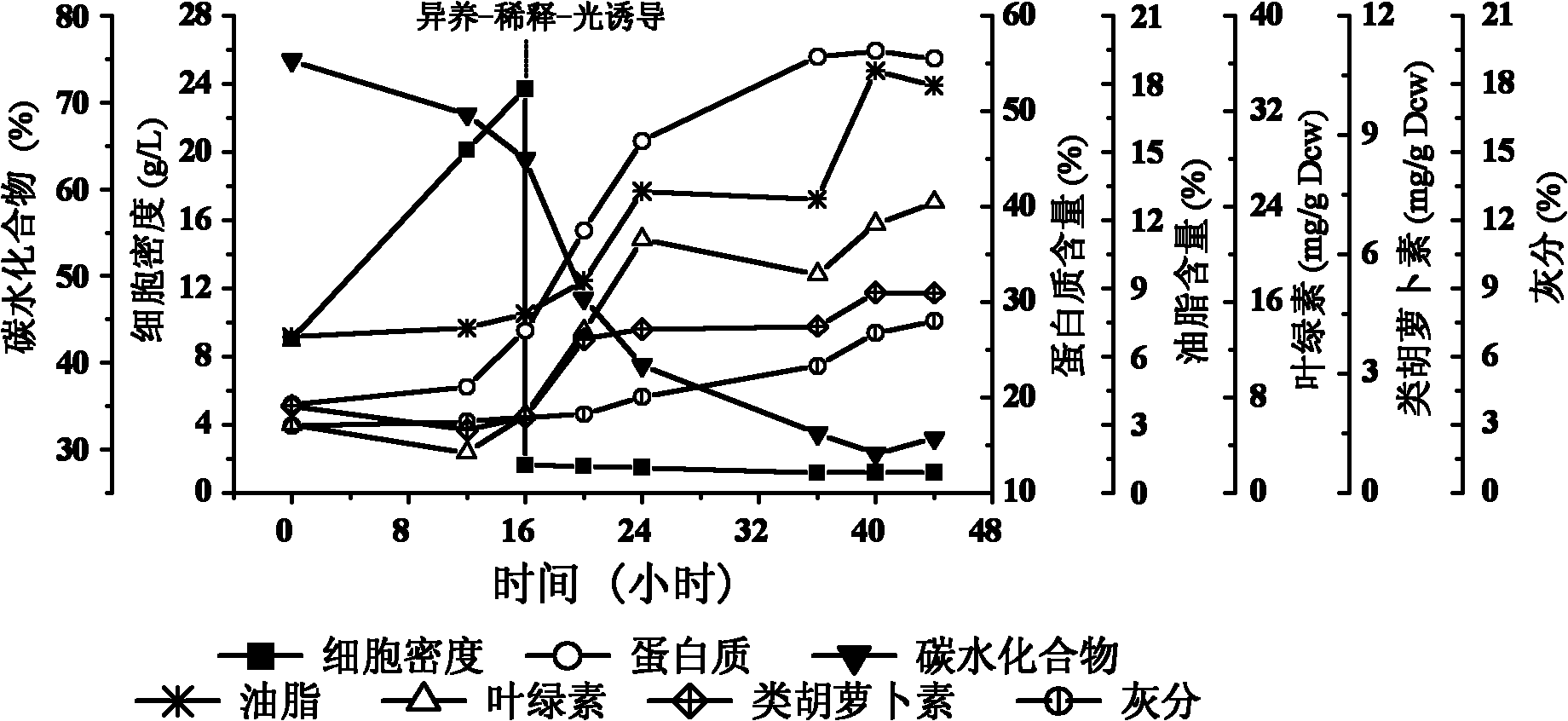

[0131] Example 3: Research on the Changes of the Main Biochemical Components of Chlorella ellipsoides During Heterotrophic-Dilution-Light-Induced Series Culture

[0132] In this example, the changes of the main biochemical components in the heterotrophic-dilution-light-induced series culture process of Chlorella ellipsoides were measured at the level of a 500mL shake flask / 3L cylindrical photobioreactor.

[0133] Cultivate Chlorella ellipsoides in a manner similar to Examples 1 and 2 with heterotrophic-dilution-light-induced serial culture technology, 500mL shake flask, liquid volume 200mL, 28°C, 150rpm, until the algae cell density reaches above 10g / L And when the glucose is exhausted, transfer to a 3L cylindrical photobioreactor for light-induced culture, the algae cell density is about 2g / L, the temperature is 30°C, and the light intensity is 10Klx. The medium used for heterotrophy and light induction is the same as the corresponding medium for Chlorella pyrenoidosa. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com