Acidic normal temperature degreasing agent and preparation method thereof

A degreasing agent, acidic technology, applied in the field of acidic normal temperature degreasing agent, can solve problems such as over-corrosion, hazards, and surrounding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0008] Example 1: ①Use a container to heat 350L of pure water to about 60°C and add it to the stirring tank. ② Turn on the stirring tank and put 20kg of linear sodium alkylbenzenesulfonate, 15kg of secondary alkylbenzenesulfonate, 110kg of sodium tripolyphosphate, 2kg of hexamethylenetetramine, Add 20kg of sulfonate, 5kg of alkanolamide, 1kg of EDTA, and 5kg of sodium lauryl sulfate into the stirring tank for dissolution. ③ Add pure water to a volume of 1000L and stir well.

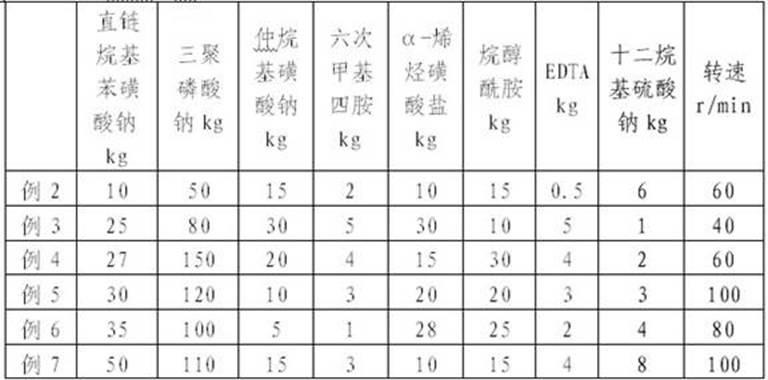

[0009] Each component and preparation method of example 2 to example 7 are as follows;

[0010]

[0011] The preparation steps of the above examples 2 to 7 are as described in example 1.

[0012] The acidic normal temperature degreasing agent of the present invention has been tested for main purposes and characteristics:

[0013] Appearance Milky white liquid

[0014] PH (stock solution) 7.5~7.6

[0015] Processing time 3-5% by weight of the degreasing agent stock solution plus 200-300ml / L hydroch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com