Method of monitoring function of selective catalytic reaction (SCR) catalyst

A SCR catalytic converter and functional technology, which is applied in the direction of machines/engines, electronic control of exhaust gas treatment devices, diagnostic devices of exhaust gas treatment devices, etc., can solve problems such as can not give qualitative analysis, leakage pressure, leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

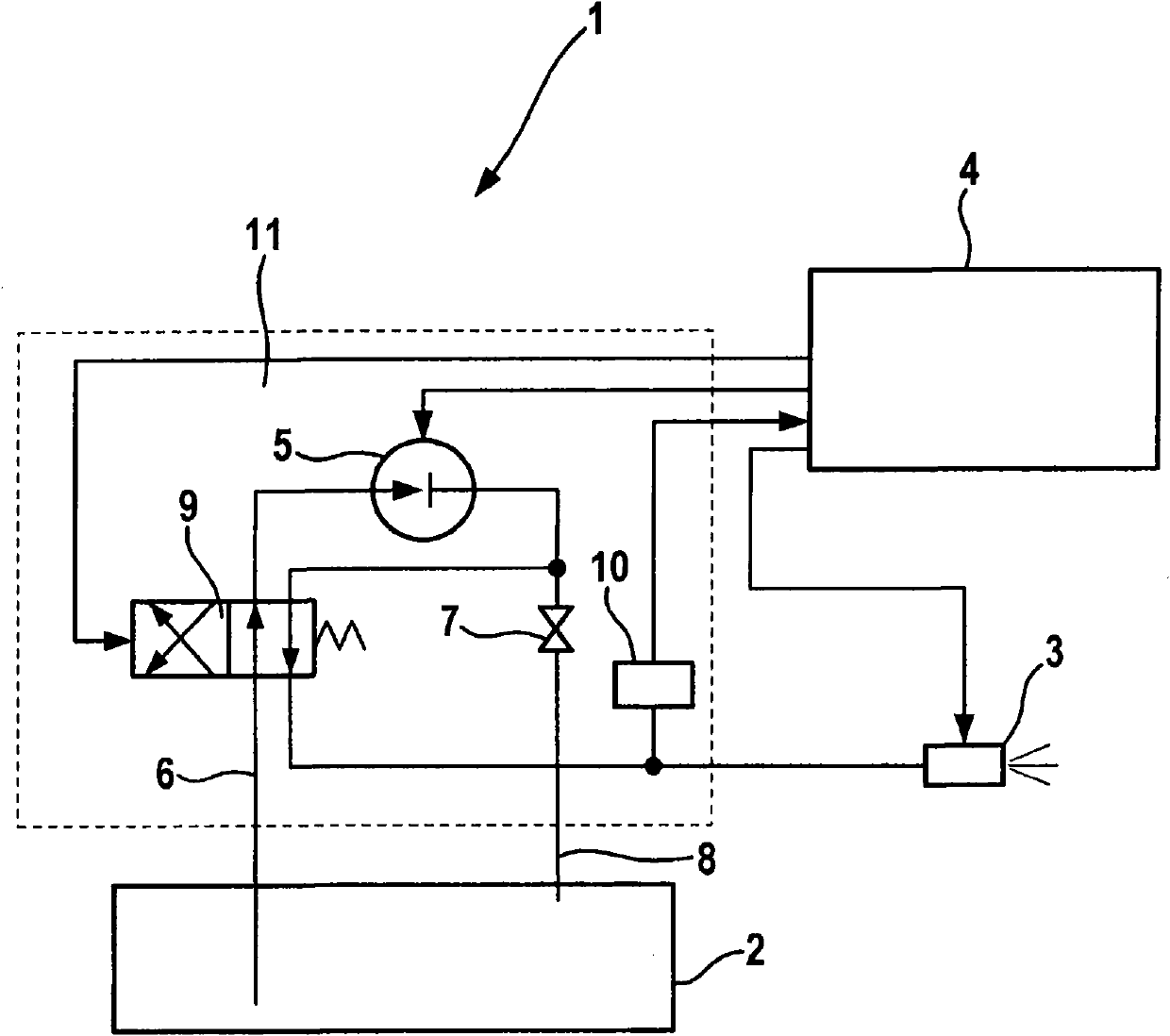

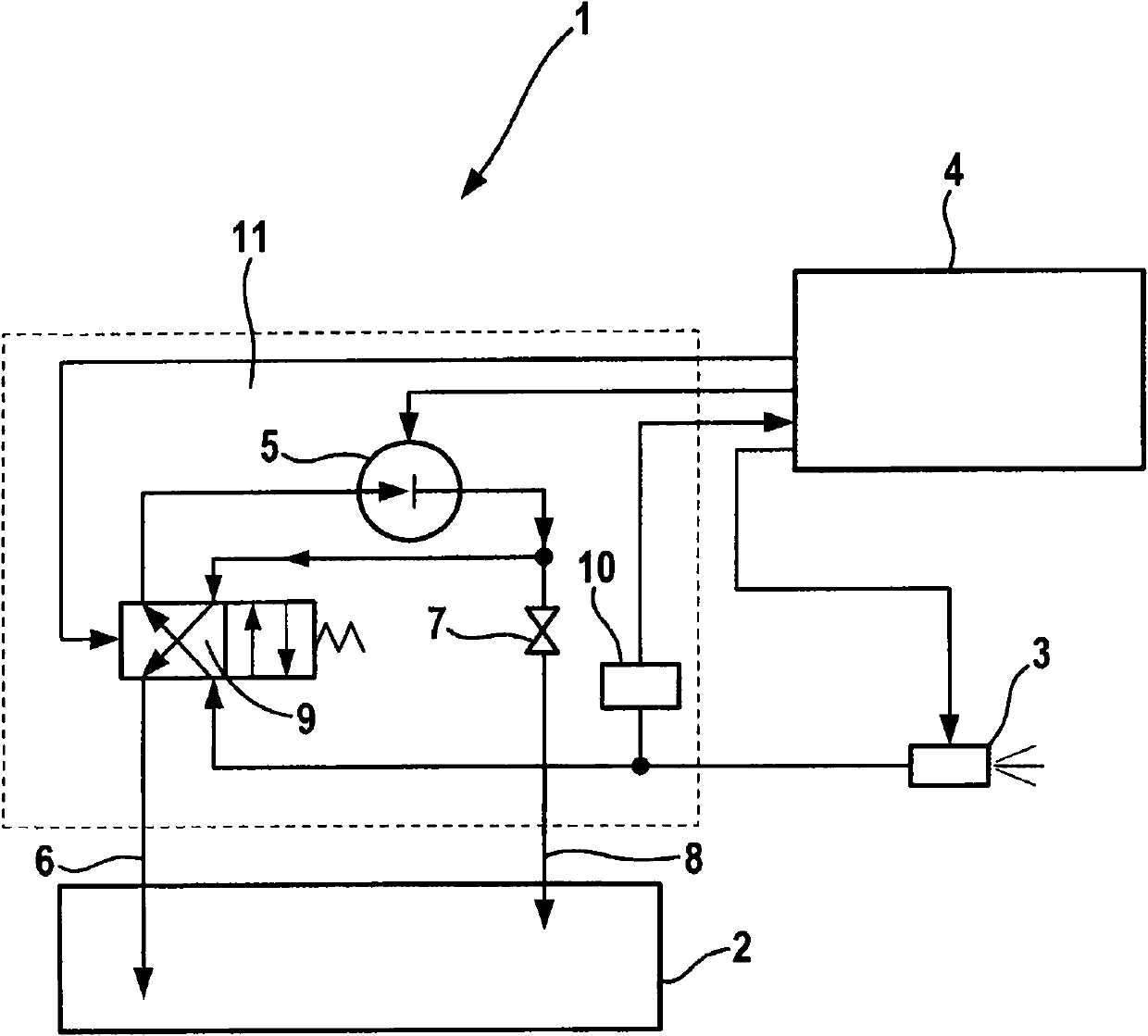

[0023] FIG. 1 shows in a schematic diagram the various elements of an SCR catalytic converter system 1 known from the prior art. The SCR catalytic converter system 1 is provided for the aftertreatment of exhaust gases of an internal combustion engine (not shown). For this purpose, the fluid reducing agent, which is stored in the reducing agent tank 2 , is injected under pressure into the exhaust gas system via the metering valve 3 . The metering valve 3 is, for example, an electromagnetic injection valve, which is controlled by a controller 4 . The reducing agent is discharged from the reducing agent tank 2 via a suction line 6 by means of a pump 5 (which has an integrated non-return throttle valve) and is fed under pressure via a line system to the metering valve 3 . For pressure regulation, an orifice 7 is provided, which is arranged downstream of the return line 8 in the reducing agent tank 2 . To switch on the medium flow, a 4 / 2-way valve 9 is provided, which is controll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com