Variable-temperature microscopic magnetic photoelectric testing system with flexible measuring geometry

An optoelectronic testing and geometric technology, which is applied in measurement devices, color/spectral property measurement, fluorescence/phosphorescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

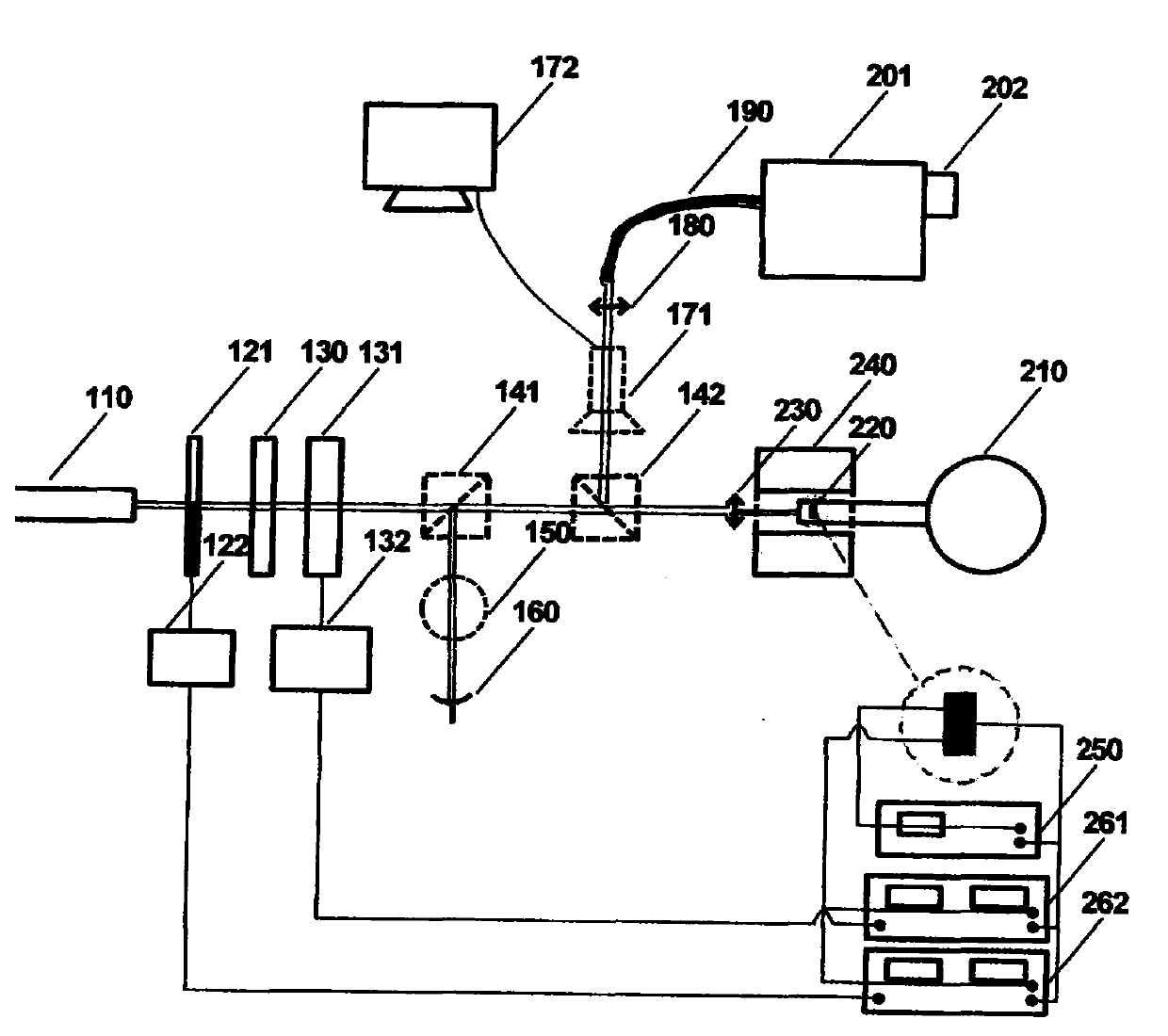

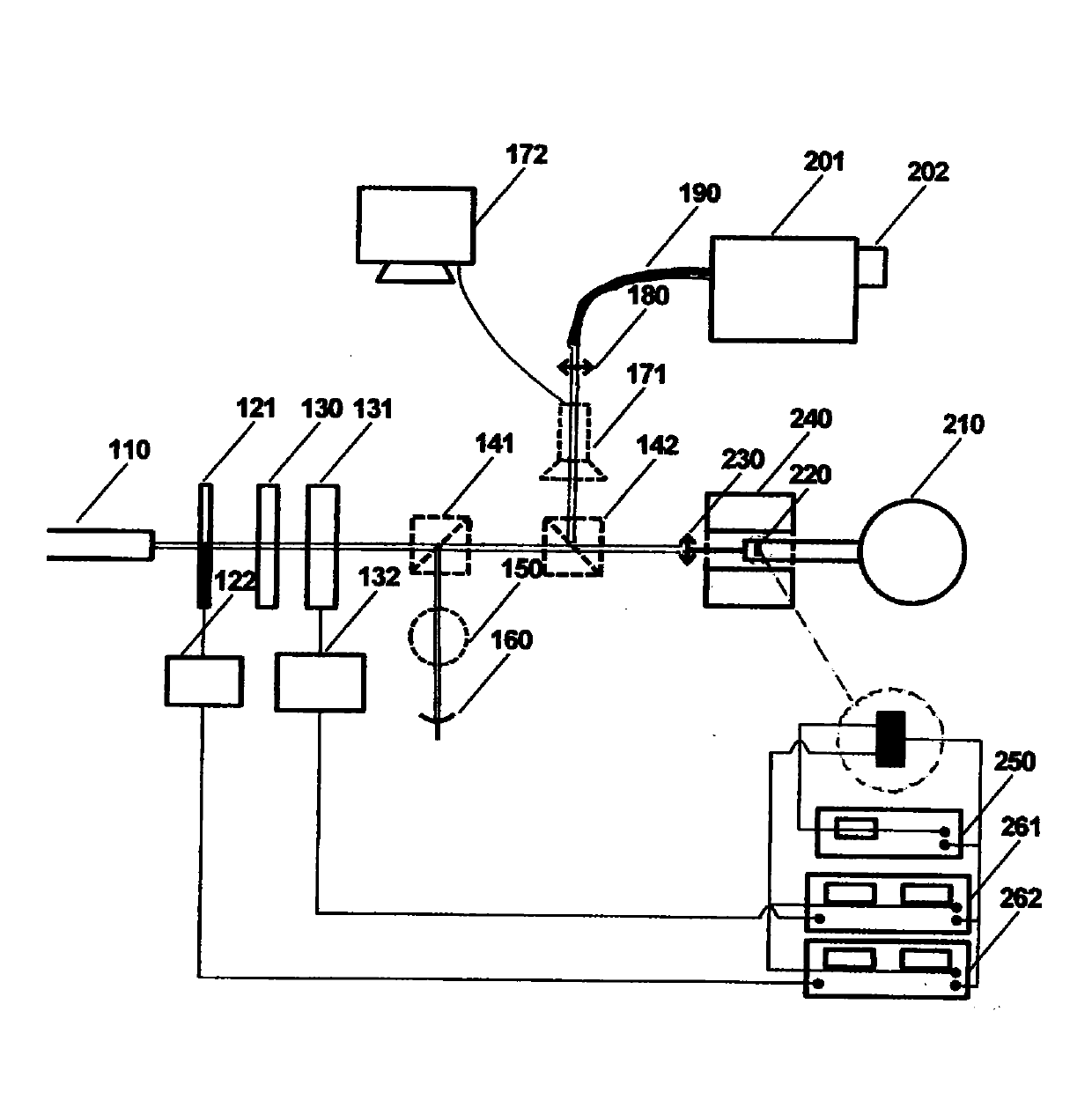

[0032] The invention is a set of temperature-variable micro-magneto-optical test system with flexible measuring geometry.

[0033] First introduce the composition of this system in detail, please refer to figure 1 As shown, the system includes:

[0034] A titanium-doped sapphire laser 110, used to excite the sample 220, a chopper 121, a broadband linear polarizer 130, a photoelastic modulator 131, and a first broadband depolarizer are arranged in sequence on the outgoing optical path of the titanium-doped sapphire laser 110 Dichroic prism 141 , second broadband depolarizing dichroic prism 142 , first objective lens 230 and liquid nitrogen Dewar 210 .

[0035] The emission wavelength of the titanium-doped sapphire laser 110 is adjustable within the range of 700-1030 nanometers, so that various behaviors of carriers with different energies in the sample 220 can be studied.

[0036] The chopper 121 is connected to a controller 122 for light intensity modulation of the excitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com