Power-generating interconnected topological structure of transformerless water-turbine generator

A technology of hydroelectric generator and topological structure, which is applied in the direction of electrical components, single-network parallel feeding arrangement, and conversion of AC power input to DC power output, etc., which can solve the problem of long production cycle, large investment, and the speed of the turbine cannot reach 50Hz and other issues to achieve the effect of improving efficiency and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

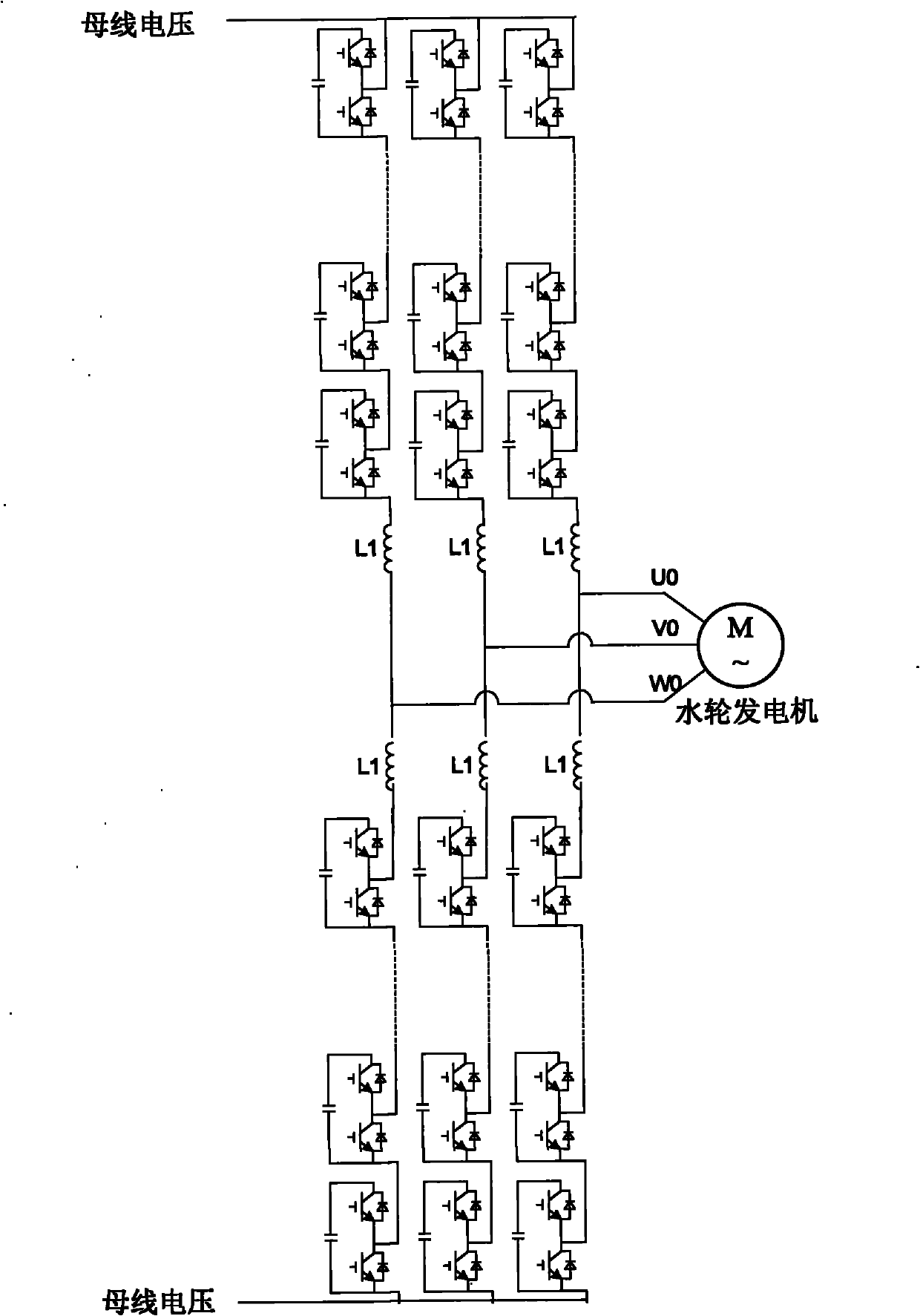

[0036] See figure 2 , image 3 , Figure 7, the subunits of rectification topology and inverter topology are half-bridge structures. As shown in Figure 7, its structure is composed of switching devices IGBT1 and IGBT2 and a DC side capacitor C. The switching devices IGBT1 and IGBT2 are connected in series, and then the DC capacitor C is connected in parallel, and the switching devices IGBT1 and IGBT2 are respectively antiparallel with diodes D1 and D2; IGBT1 and IGBT2 The common terminal of capacitor C and IGBT2 is used as the output terminal of each unit and connected with other units.

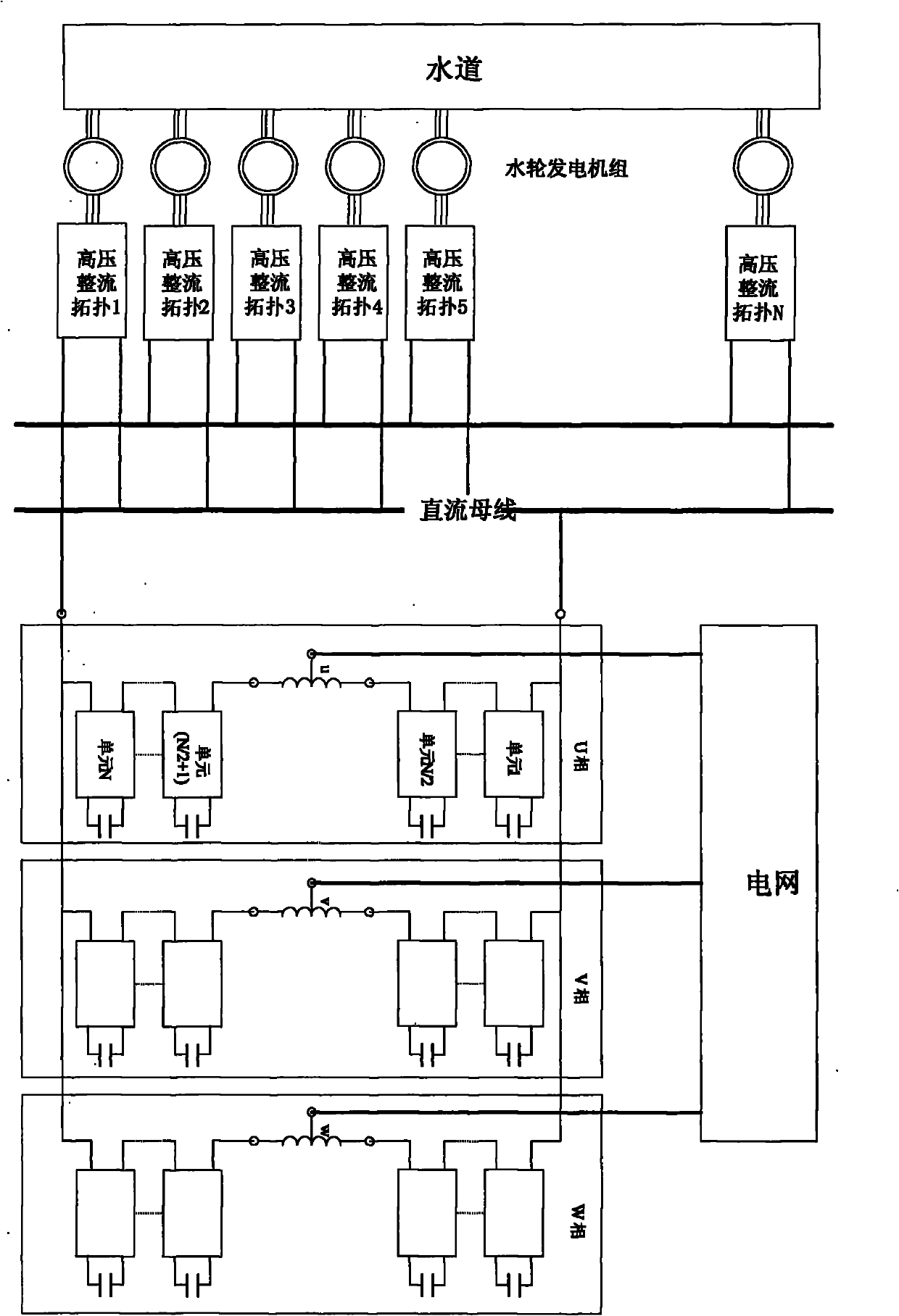

[0037] On the rectification side, multiple hydro-generators generate high-voltage alternating current of any frequency. Each hydro-generator M obtains DC high voltage after being rectified by the high-voltage rectification topology. On the bus, the voltage on the DC bus is used as the DC side voltage of the inverter topology. After the DC side voltage is converted into an AC voltage by the ...

Embodiment 2

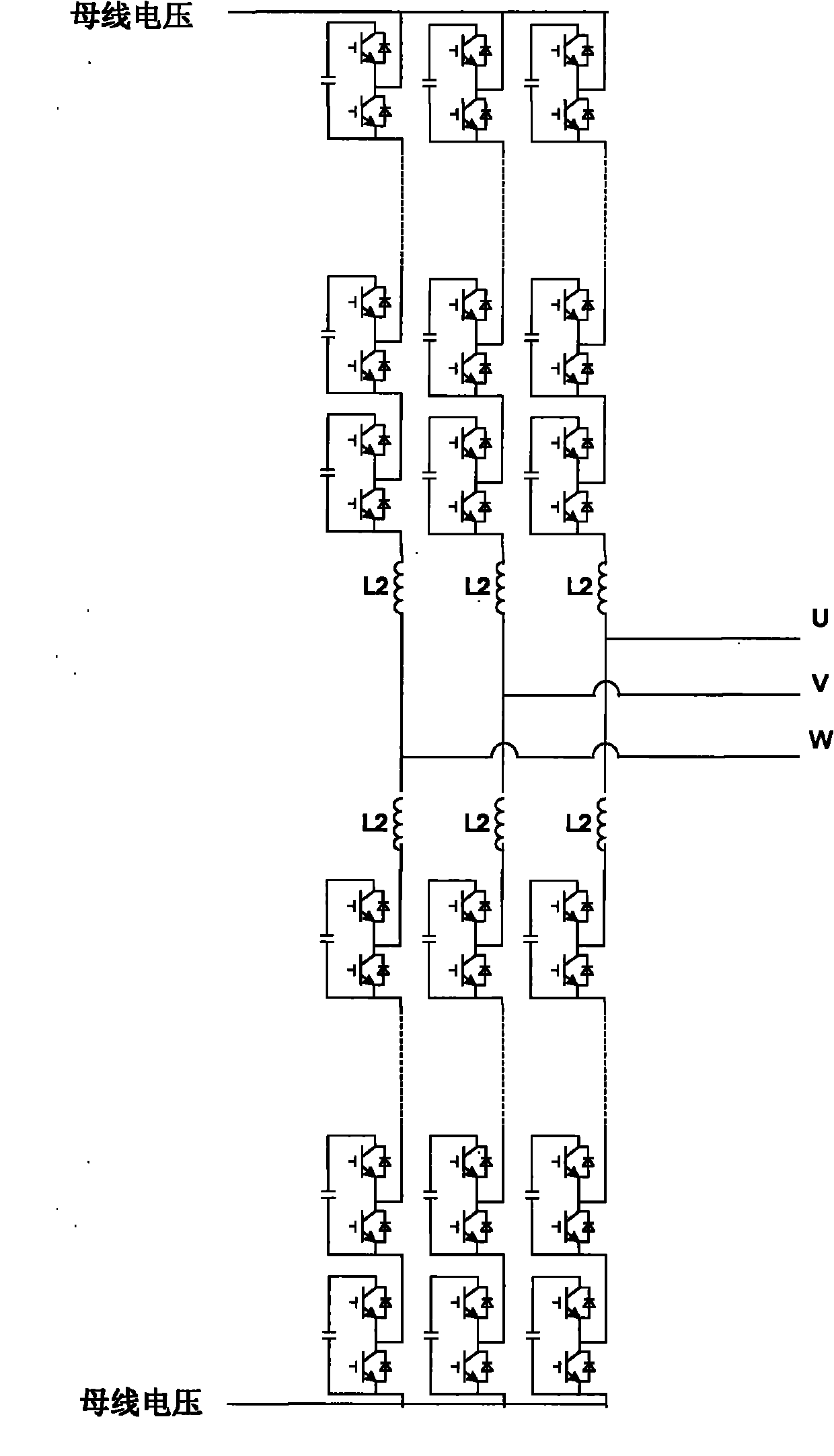

[0043] See Figure 4 , Figure 5, Figure 8, the subunits of rectification topology and inverter topology are H-bridge structures. As shown in Figure 8, its structure consists of four switching devices IGBT1, IGBT2, IGBT3, IGBT4 and a DC side capacitor C. The switching devices IGBT1 and IGBT2 are connected in series, the switching devices IGBT3 and IGBT4 are connected in series, and then connected in parallel with the DC capacitor C. In addition, the four switching devices IGBT1, IGBT2, IGBT3, IGBT4 are respectively connected in parallel with a reverse diode D1, D2, D3, D4. The common end of IGBT1 and IGBT2, and the common end of IGBT3 and IGBT4 are input and output ends for connecting the power unit to other power units.

[0044] On the rectification side, multiple hydro-generators generate high-voltage alternating current of any frequency. Each hydro-generator M obtains DC high voltage after being rectified by the high-voltage rectification topology. On the bus, the voltag...

Embodiment 3

[0050] See Image 6 , the high-voltage rectification topology is an uncontrollable structure composed of multiple diodes connected in series. The inverter topology is three-phase, and each phase of the inverter module is composed of an even number of n subunits in series, which are divided into upper and lower groups. The number of units in each group is n / 2, and the number of output phase voltage levels is n / 2. +1, the number of line voltage levels is n+1; the output terminal of the inverter module is at the midpoint of the two groups of units, and the output terminal is connected to each group of units with coupling or non-coupling inductance.

[0051] On the rectification side, multiple hydro-generators generate high-voltage alternating current of any frequency. Each hydro-generator M obtains DC high voltage after being rectified by the high-voltage rectification topology. On the bus, the voltage on the DC bus is used as the DC side voltage of the inverter topology. After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com