Multi-blade solid carbide drill

A solid carbide, drilling tool technology, used in drilling accessories, drilling/drilling equipment, tools for lathes, etc. Possibility, exclusion of sudden breakage, effect of shortening chip length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

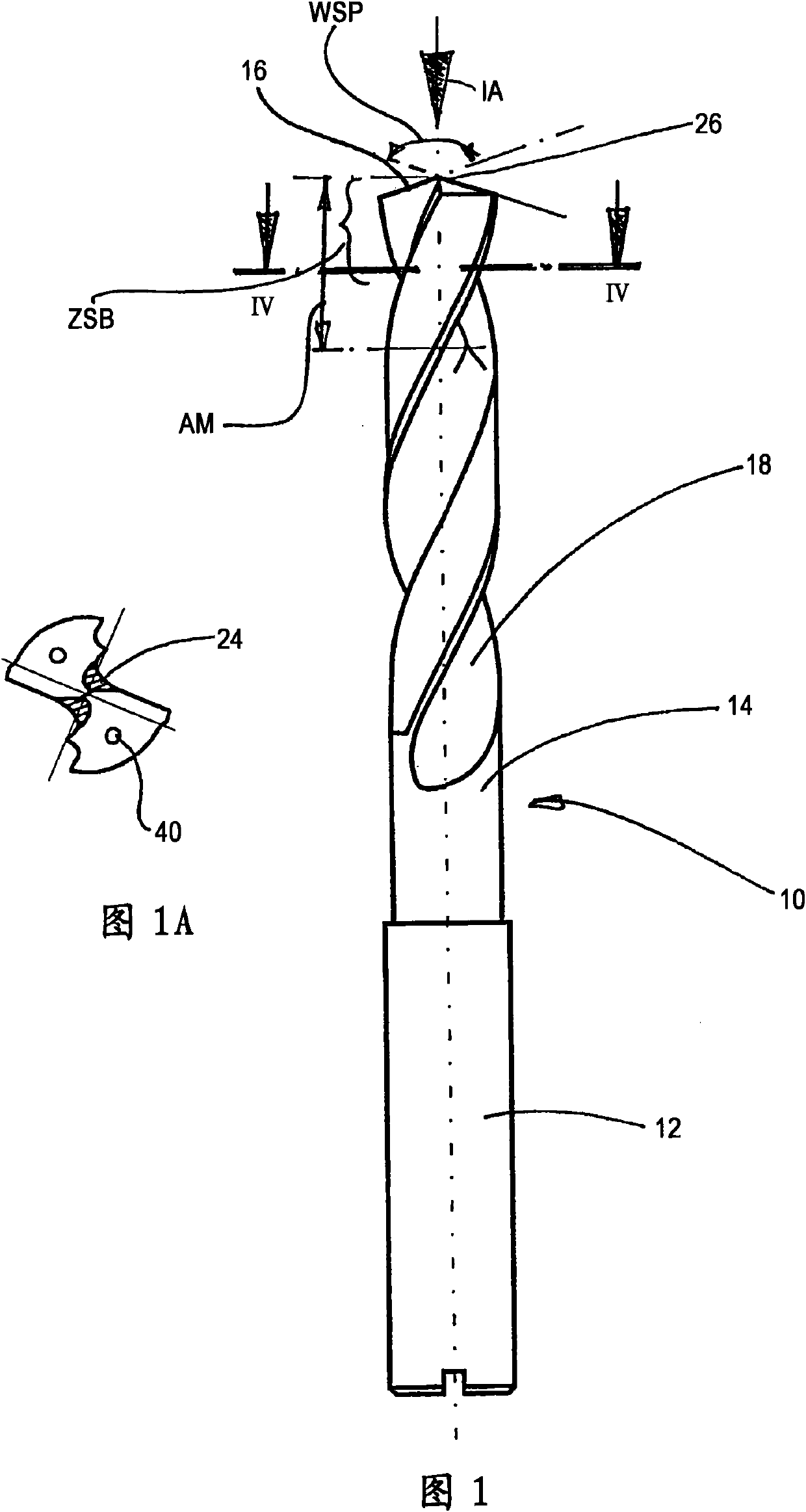

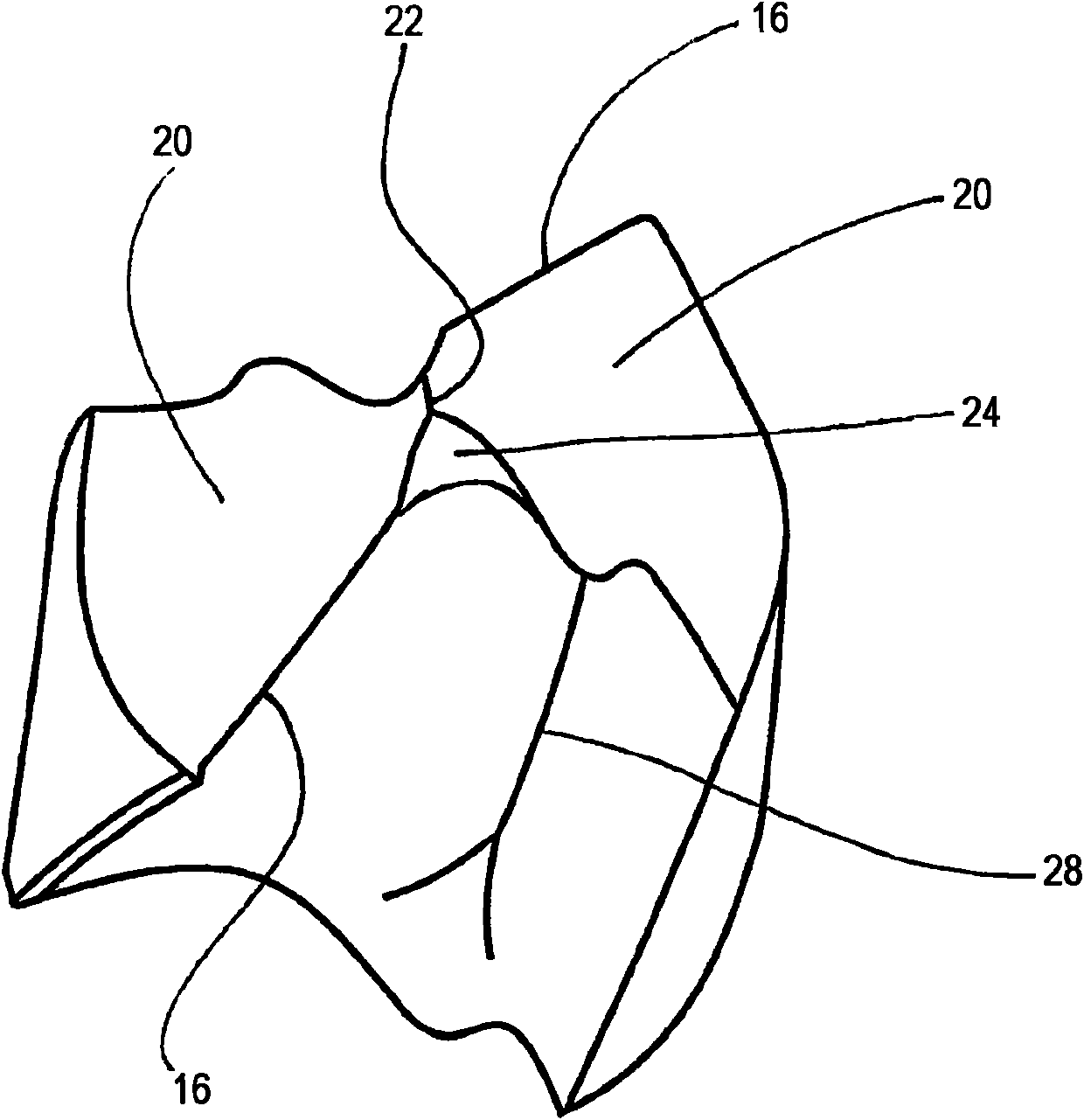

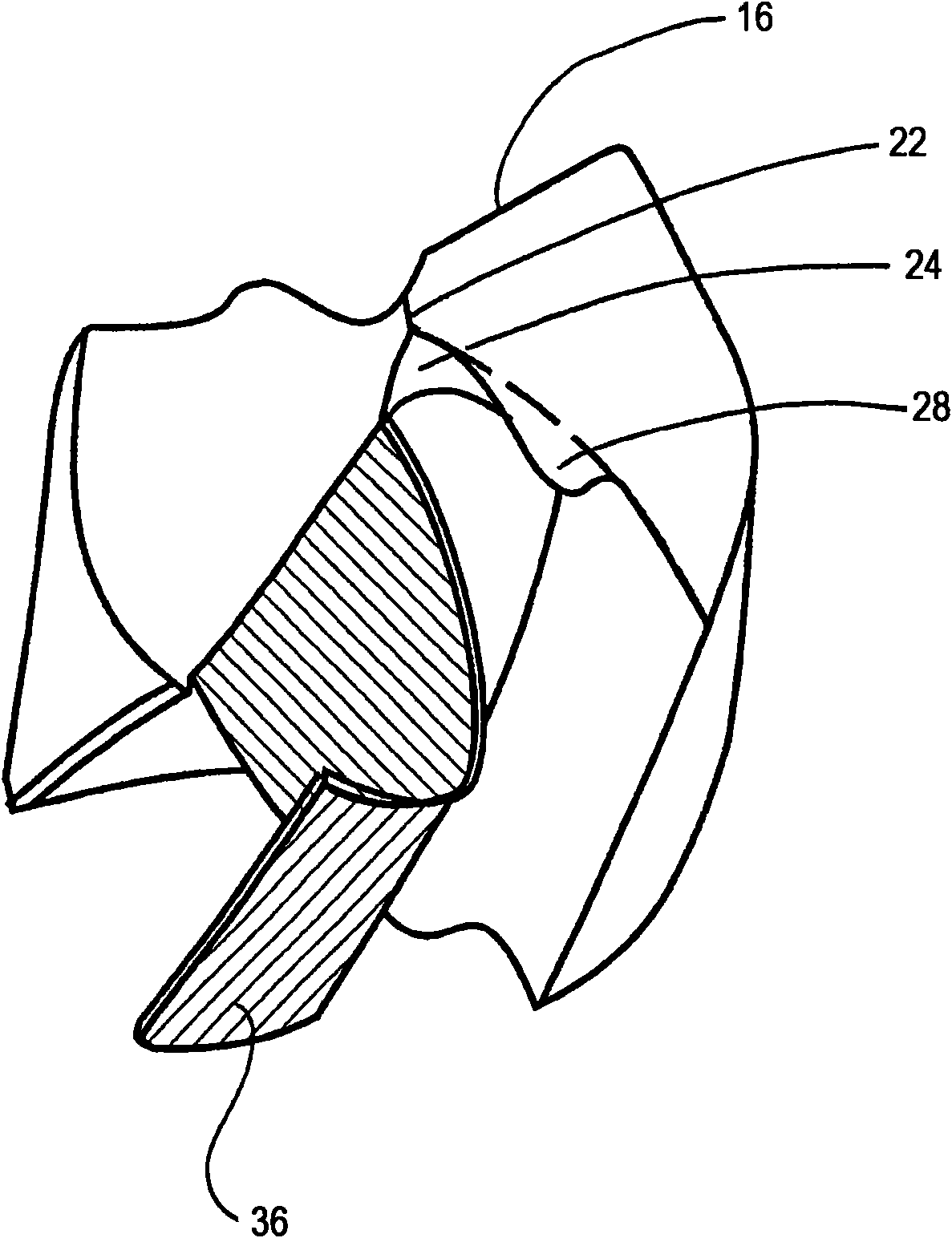

[0027] The tool shown in the figures consists of solid carbide, preferably fine-grained carbide. Cemented carbide species of this type have been known for a long time, so a detailed description of the material can be omitted. It is decisive that the cemented carbide should have high toughness in the sintered state and should offer the possibility of forming stable and precise cutting edges due to the fine grain size.

[0028] Said tool is used in particular for cutting high-strength multilayer structural materials, and more particularly for drilling holes in solid bodies of such materials, which usually have layers comprising alternating layers of carbon fiber reinforced plastic, aluminum A composite structure of layers and titanium layers, wherein the sequence of the layers can vary depending on the purpose of application. When machining holes, especially deep holes whose depth is a multiple of the nominal diameter of the borehole to be produced, these layers require on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com