New process for preparing high-purity magnesium oxide by normal temperature carbonization and low temperature pyrolysis

A technology of low-temperature pyrolysis and magnesium oxide, which is applied in lime production and other fields, can solve problems such as high cost, low product quality, and large coal consumption, and achieve high equipment utilization, good compatibility, and energy saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

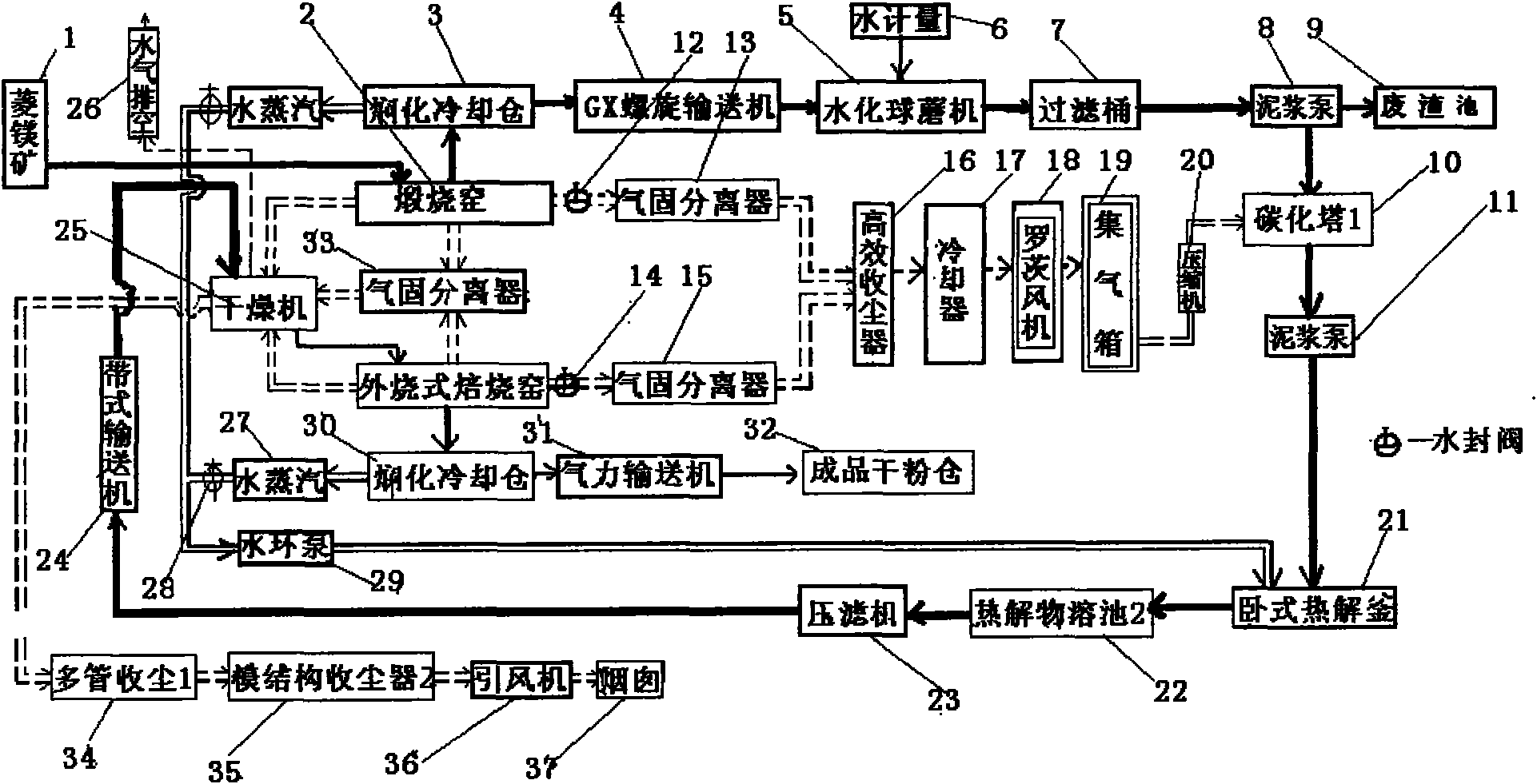

[0023] The new process of high-temperature pyrolysis and low-temperature carbonization of high-purity magnesium oxide proposed by the patent of the present invention, its process structure is as follows figure 1 As shown, it includes raw material ore coarse (jaw type) crusher 29, the bottom of belt conveyor 19 is connected with 29 outlets, the upper part is connected with 18 upper ports, fine broken (hammer broken) machine 18, and the bottom of hoist 16 is connected with 18 outlets , the upper part is connected with the feed inlet of 15, the metering device 13 is installed at the bottom of the feed bin 15, the bottom of the large-inclination belt conveyor 10 is connected with 13, and the upper part is connected with the hopper on the upper part of the feed inlet of one end of the externally fired raw ore calcining kiln 4 ;The fuel system is connected with the large-inclination belt conveyor 1 at the bottom outlet of the coal breaker 3, and the upper part is connected with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com