Processing agent for polyolefin and alloy thereof, preparation method and application thereof

A processing aid and polyolefin technology, applied in the field of processing aids for polyolefin and its alloys and its preparation and application, can solve the problems of fluorine decomposition pollution, long effective time, difficult to clean, etc., and achieve easy operation, Short effective time and good viscosity reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

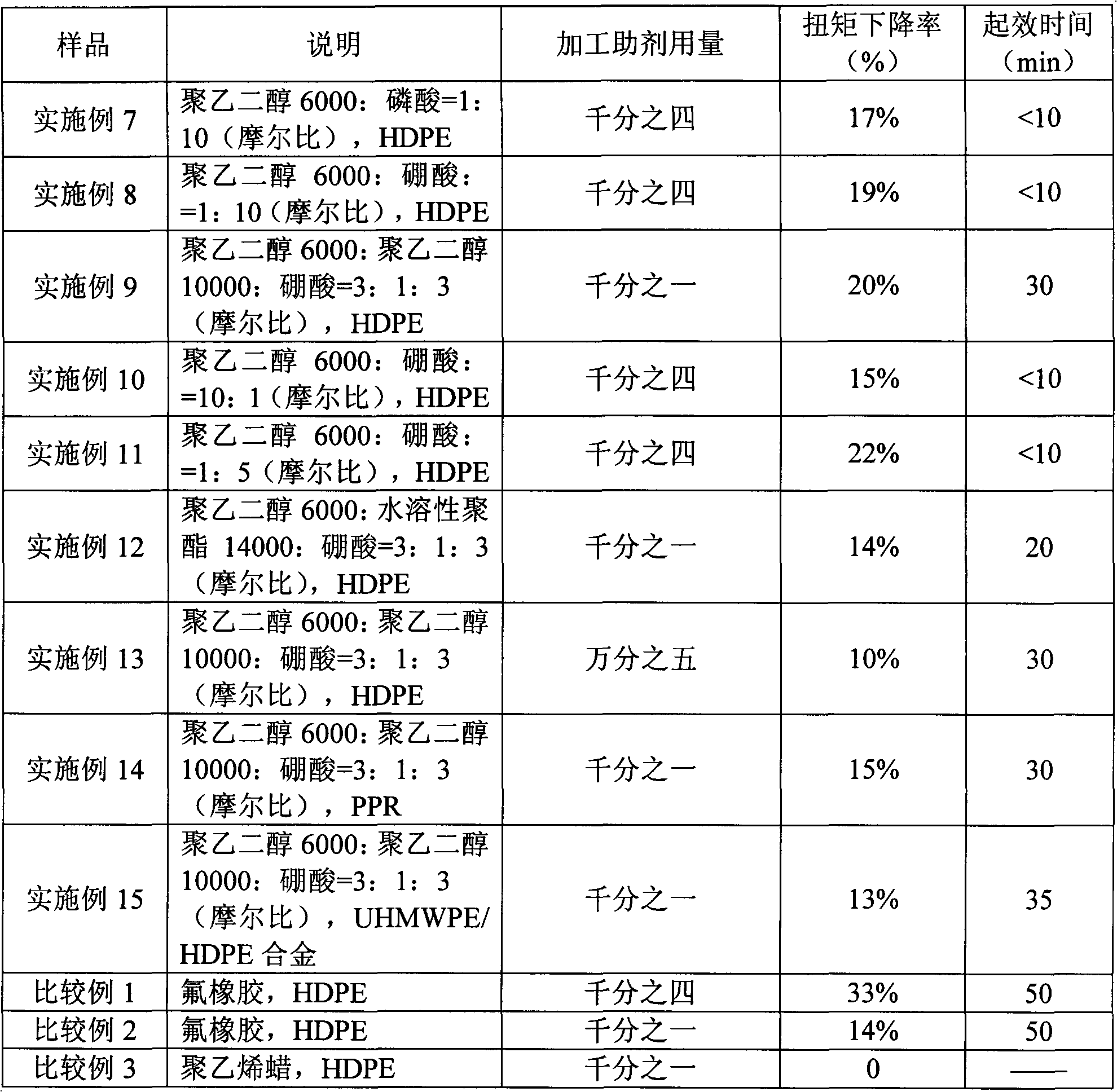

Examples

Embodiment 1

[0022] A beaker containing 100 grams of polyethylene glycol 6000 (Sinopharm Chemical Reagent Company, imported from Japan, molecular weight 5500-7000) was placed in a water bath and heated to 80 degrees. After polyethylene glycol is melted, put in 19.2 grams of phosphoric acid (analytical grade, Beijing Chemical Plant) and stir evenly with a glass rod. Thereafter, stir once every 10 minutes. After 60 minutes, take the beaker out of the water bath and place it at room temperature. After the melt solidifies, grind it to obtain a powder processing aid. (processing aid 1)

Embodiment 2

[0024] Replace 19.2 grams of phosphoric acid with 10.4 grams of boric acid (analytically pure, Beijing Chemical Plant), and all the other conditions are the same as in Example 1. (processing aid 2)

Embodiment 3

[0026] Put polyethylene glycol 6000 (Sinopharm Group Chemical Reagent Company, Japan import subpackage, molecular weight 5500-7000) 45 grams and polyethylene glycol 10000 (Beijing Chemical Reagent Company, Japan import subpackage) 25 grams into the beaker In a water bath, heat the water bath to 80°C, put 0.5 g of boric acid into the melted polyethylene glycol and stir evenly with a glass rod. Thereafter, stir once every 10 minutes. After 60 minutes, take the beaker out of the water bath and place it at room temperature. After the melt solidifies, grind it to obtain a powder processing aid. (processing aid 3)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com