Fireproof door leaf

A door and door leaf and fireproofing liquid technology, which is applied in the field of building fireproof components, can solve the problem of low fireproof door and door leaf, and achieve the effects of long fire resistance time, strong pressure resistance and stable quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

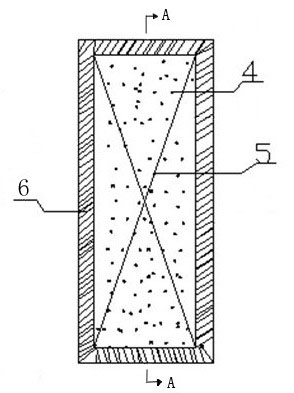

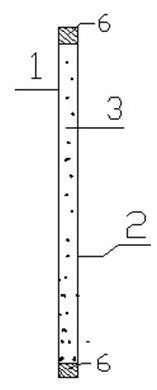

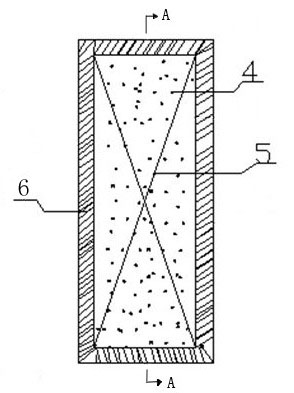

[0015] Embodiment one : see figure 1 and figure 2 A fireproof door leaf as shown, including a bottom layer 1, a surface layer 2, an intermediate layer 3 sandwiched between the bottom layer and the surface layer, and an edge banding frame arranged around the middle layer and between the bottom layer and the surface layer 6. The middle layer 3 is composed of a grid 5 and a fireproof material 4 filled in the grid;

[0016] The fireproof material 4 is made by mixing 65% by weight of white foam stone particles, 20% by weight of magnesium chloride solution, 13% by weight of magnesium oxide, and 2% by weight of modifier, wherein the particle size of white foam stone particles is 20 mesh-500 mesh The weight percent concentration of order, magnesium chloride solution is 25%.

[0017] The grid shape of the grid 5 is triangular, the thickness of the grid 5 is equal to that of the edge banding frame 6, the bottom surface layer 1 and the surface layer 2 are steel plates, and the edge ...

Embodiment 2

[0020] Embodiment two : see figure 1 and figure 2 A fireproof door leaf as shown, including a bottom layer 1, a surface layer 2, an intermediate layer 3 sandwiched between the bottom layer and the surface layer, and an edge banding frame arranged around the middle layer and between the bottom layer and the surface layer 6. The middle layer 3 is composed of a grid 5 and a fireproof material 4 filled in the grid;

[0021] The fireproof material 4 is made by mixing 75% by weight of white foam stone particles, 14% of magnesium chloride solution, 10% of magnesium oxide, and 1% by weight of modifier, wherein the particle size of white foam stone particles is 20-500 mesh The weight percent concentration of order, magnesium chloride solution is 22%.

[0022] The grid shape of the grid 5 is rhombus and triangle, the thickness of the grid 5 is equal to the thickness of the edge banding frame 6, the bottom surface layer 1 and the surface layer 2 are wooden boards soaked in fireproof...

Embodiment 3

[0025] Embodiment three : see figure 1 and figure 2 A fireproof door leaf as shown, including a bottom layer 1, a surface layer 2, an intermediate layer 3 sandwiched between the bottom layer and the surface layer, and an edge banding frame arranged around the middle layer and between the bottom layer and the surface layer 6. The middle layer 3 is composed of a grid 5 and a fireproof material 4 filled in the grid;

[0026] The fireproof material 4 is made by mixing 40% by weight of white foam stone particles, 35% by weight of magnesium chloride solution, 22% by weight of magnesium oxide, and 3% by weight of modifier, wherein the particle size of white foam stone particles is 20 mesh-500 The weight percent concentration of order, magnesium chloride solution is 30%.

[0027] The grid shape of the grid 5 is quadrilateral, the thickness of the grid 5 is equal to the thickness of the edge banding frame 6, the bottom surface layer 1 and the surface layer 2 are fireproof glass pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com