Pulverized coal burner and boiler with same

A pulverized coal burner and pulverized coal technology are applied in the burners, burners, and combustion of multiple fuels, etc., which can solve the problem of destroying the pulverized coal combustion atmosphere, reducing the combustion efficiency of boilers, and weakening and suppressing nitrogen oxides. and other problems to achieve the effect of improving stiffness, improving adaptability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

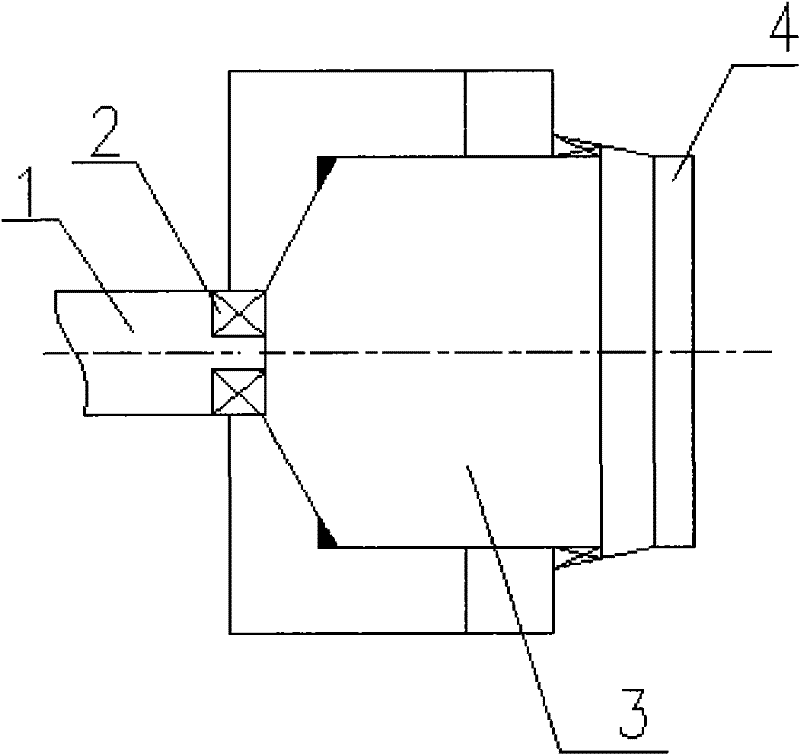

[0052] Please refer to image 3 , which is a schematic structural view of the pulverized coal burner provided in Embodiment 1. The pulverized coal burner includes a fire source 200 and an internal combustion chamber 100, the internal combustion chamber 100 has an inlet 101 and an outlet 102, and a long cylindrical main combustion chamber is formed in it to form a suitable space to maintain the internal pulverized coal flow with a predetermined excess air factor. In this example, the internal combustion chamber 100 also includes a transition duct 300 communicating with the front end of the main combustion chamber, and the fire source 200 extends into the internal combustion chamber 100 from the transition duct 300; the transition duct 300 communicates with the primary air pulverized coal duct.

[0053]In the flow direction of the pulverized coal airflow, the internal combustion chamber 100 has a predetermined length and cross-sectional area, and can maintain the excess air rat...

Embodiment 2

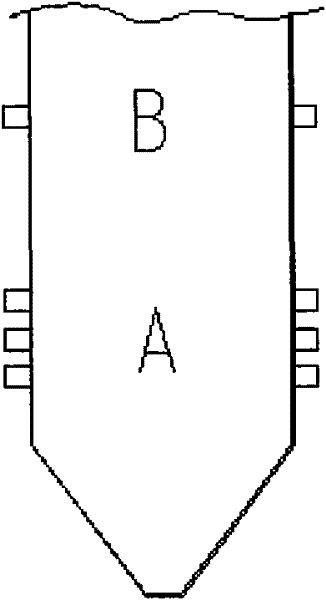

[0063] Please refer to Figure 4 , which is a schematic structural view of the pulverized coal burner provided in Embodiment 2. On the basis of Embodiment 1, the internal combustion chamber 100 includes a main combustion chamber 120 and a deceleration inlet section 110 connected to the front end of the main combustion chamber 120 , and the inlet 101 is located at the intersection of the deceleration inlet section 110 and the transition duct 300 . As shown in the figure, the cross-sectional area of the deceleration inlet section 110 is smaller than the cross-sectional area of the main combustion chamber 120 . When the pulverized coal gas flow enters the main combustion chamber 120 with a large cross-sectional area from the deceleration inlet section 110 with a small cross-sectional area, the flow velocity of the pulverized coal gas flow will decrease accordingly. In this way, when the length of the internal combustion chamber 100 remains unchanged, it takes longer for the ...

Embodiment 3

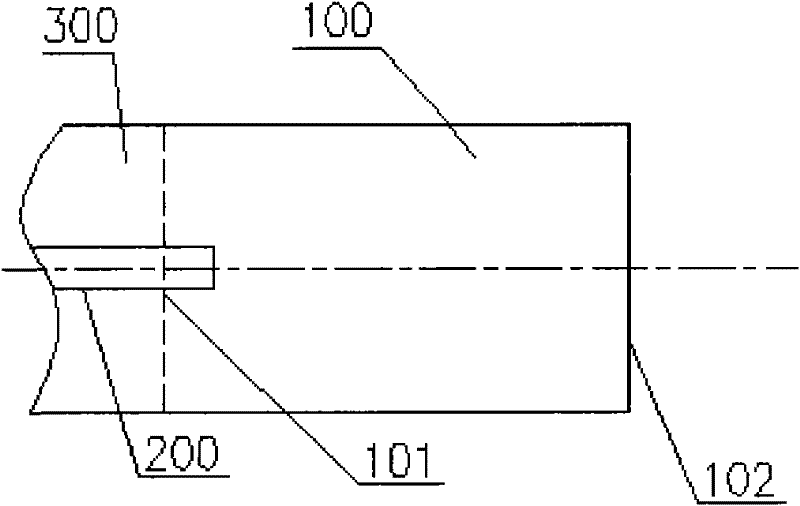

[0069] When the pulverized coal airflow ignited in the internal combustion chamber 100 is drawn out through the outlet 102 and introduced into the boiler furnace, in order to make the drawn high-temperature pulverized coal combustion flame have higher rigidity and adapt to the overall combustion organization needs of the boiler furnace, it can also be An acceleration outlet section is arranged in the internal combustion chamber 100 . like Image 6 As shown, this figure shows a schematic structural view of the pulverized coal burner provided by Embodiment 3, which also has an accelerated outlet section 130 connected to the rear end of the main combustion chamber 120; similarly, in order to ensure the pulverized coal flow Stability when the flow velocity changes, in the flow direction of the pulverized coal airflow, preferably, the cross-sectional area of the acceleration outlet section 130 gradually decreases, so that the flow velocity of the pulverized coal airflow gradually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com