Graph masking method for improving luminous efficiency of GaN base LED (light-emitting diode)

A technology of luminous efficiency and graphics, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of poor repeatability, complex process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

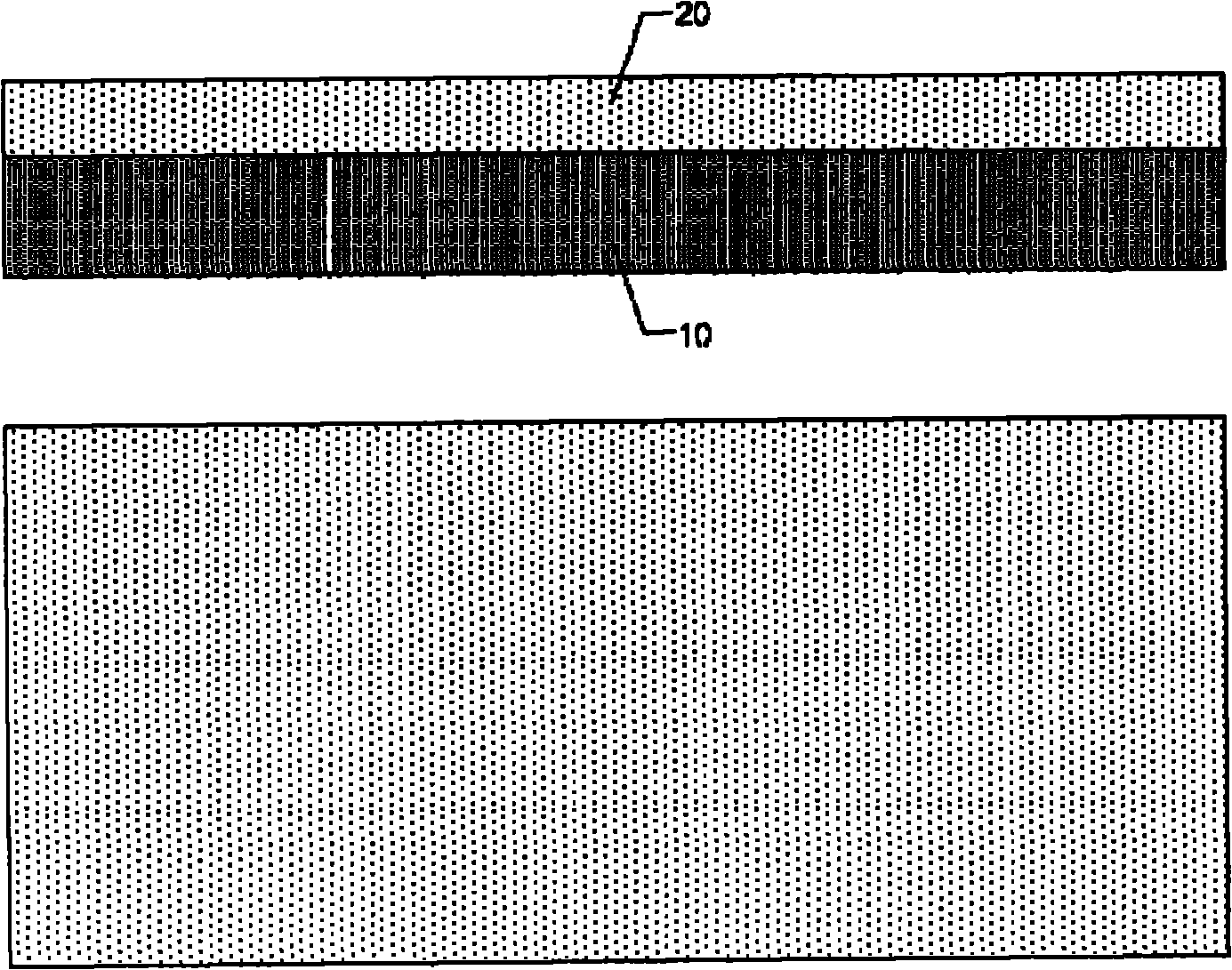

[0043] (a) if figure 1 As shown, a GaN single crystal thin film 20 with uniform thickness, flat and crack-free is grown on a sapphire substrate 10 by metal-organic vapor phase epitaxy (MOVPE). The thin film 20 has a thickness T=2000 nm.

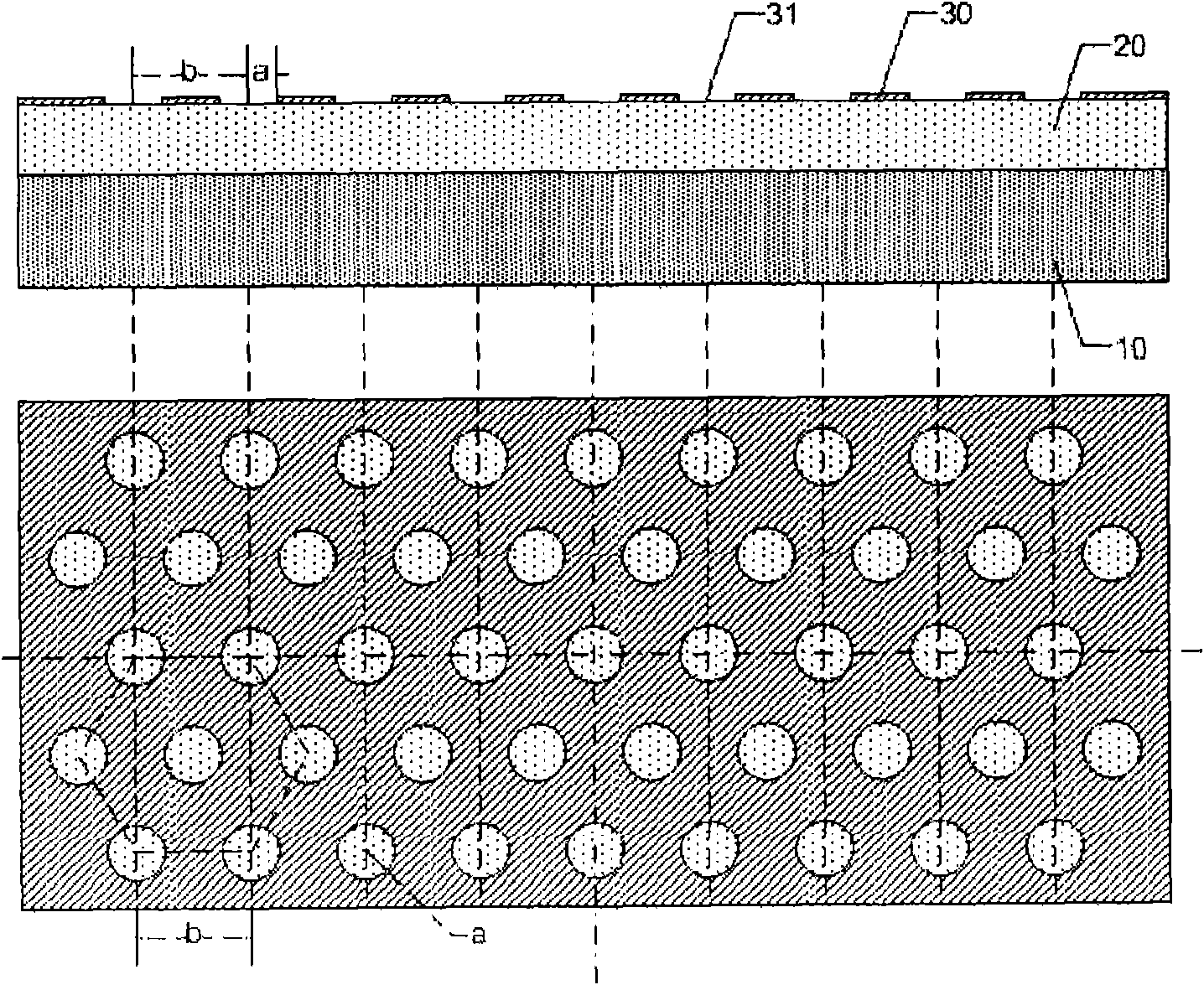

[0044] (b) if figure 2 As shown in A, a layer of photoresist mask 30 is evenly coated on the GaN thin film 20, and the thickness of the mask is c=5000nm. A regular hexagonal distribution pattern 31 is produced by using standard photolithography technology. The pattern 31 is a circular cavity with a radius a=1500nm and a minimum distance b=3000nm between adjacent circular cavities.

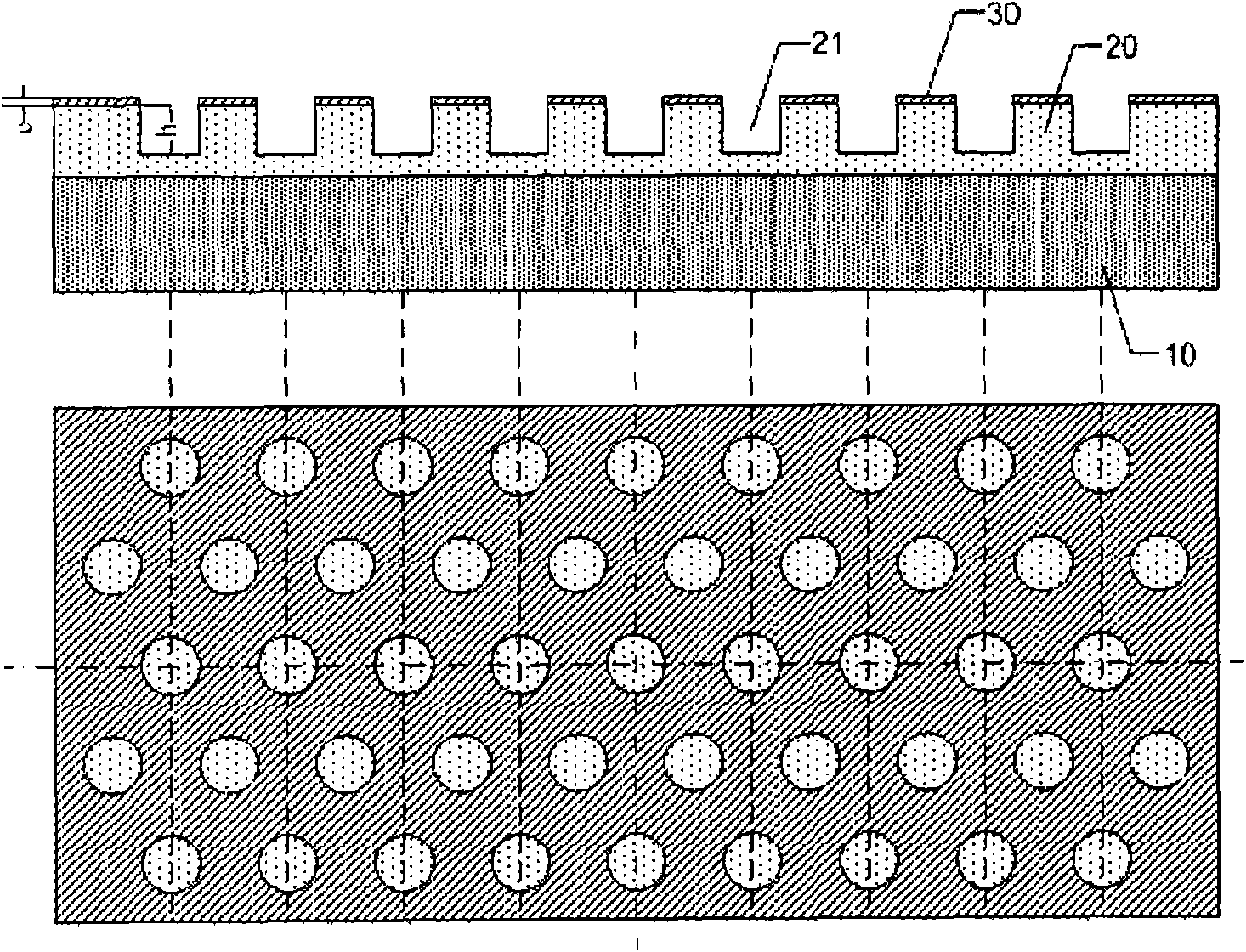

[0045] (c) if Figure 3A As shown, the GaN thin layer 20 is selectively etched using a mask 30 with regularly distributed patterns 31 . In this preferred embodiment using an inductively coupled plasma etching (ICP) method, the portion covered by the mask 30 is protected from etching, and the portion not covered by the mask 30 is etched nearly vertically downw...

Embodiment 2

[0051] (a) if figure 1 As shown, a GaN single crystal thin film 20 with uniform thickness, flat and crack-free is grown on a sapphire substrate 10 by metal-organic vapor phase epitaxy (MOVPE). The thin film 20 has a thickness T=2000 nm.

[0052] (b) if figure 2 As shown, a layer of photoresist mask 30 is uniformly coated on the GaN thin film 20, and the thickness of the mask is c=5000nm. A regular hexagonal distribution pattern 31 is produced by using standard photolithography technology. The pattern 31 is a circular cavity with a radius a=1500nm and a minimum distance b=3000nm between adjacent circular cavities.

[0053] (c) if Figure 3B As shown, the GaN thin layer 20 is selectively etched using a mask 30 with regularly distributed patterns 31 . In this preferred embodiment using an inductively coupled plasma etching (ICP) method, the portion covered by the mask 30 is protected from etching, and the portion not covered by the mask 30 is etched nearly vertically downwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com