Combination of battery protection board and battery core as well as combination method thereof

A battery protection board and cell technology, which is applied in battery pack components, secondary battery repair/maintenance, secondary batteries, etc. Cost, improve welding quality, reduce the effect of welding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

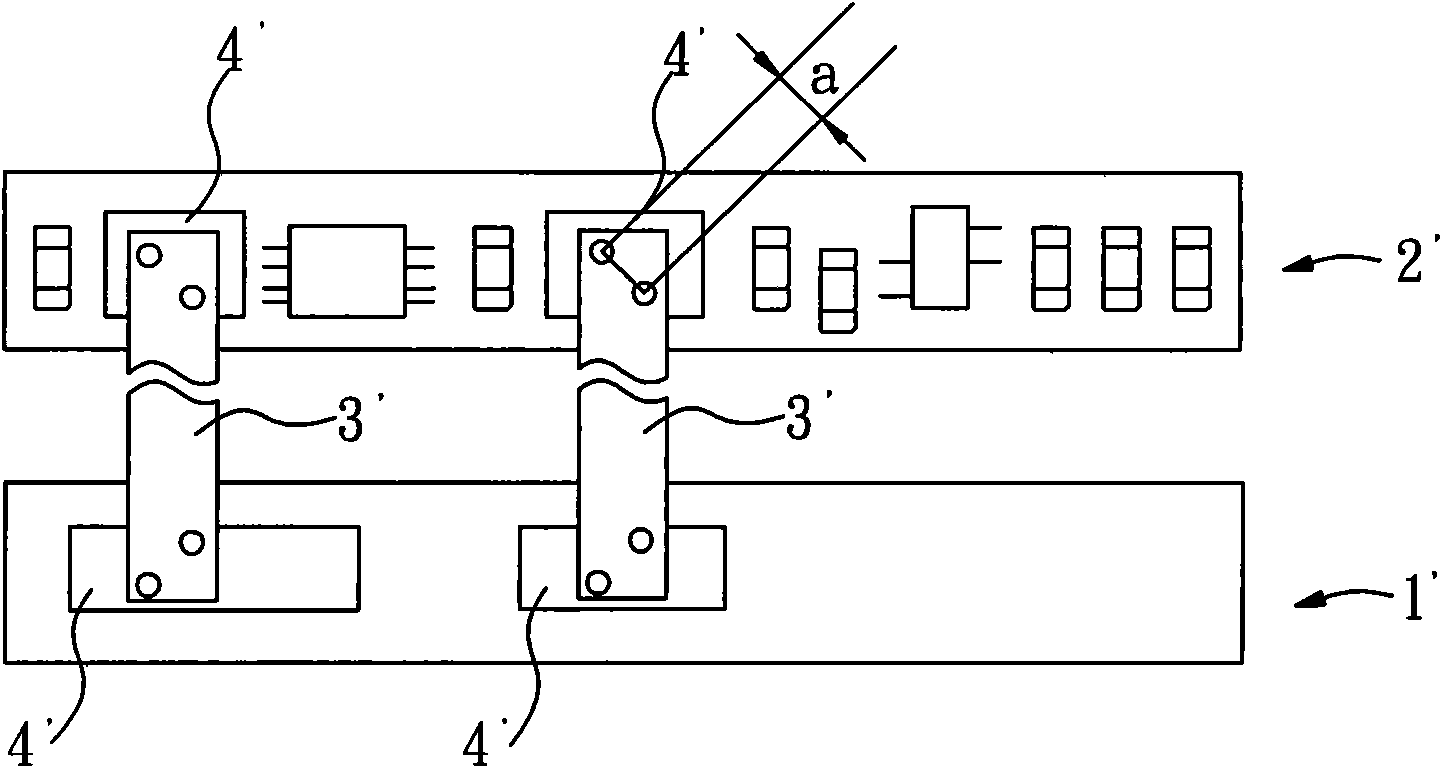

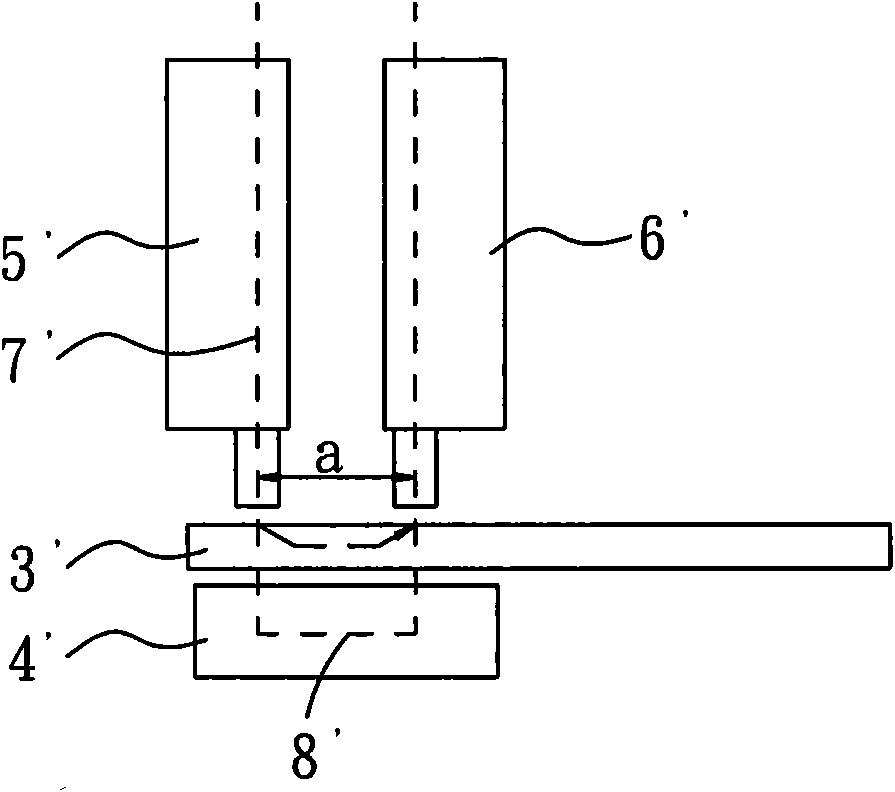

[0036] See Figure 4 with Figure 5 The combination of the battery protection board and the battery cell of the present invention includes the battery cell 1 and the battery protection board 2.

[0037] See Figure 5 , The upper end surface of the cell 1 is provided with a positive electrode sheet 11 and a negative electrode sheet 12.

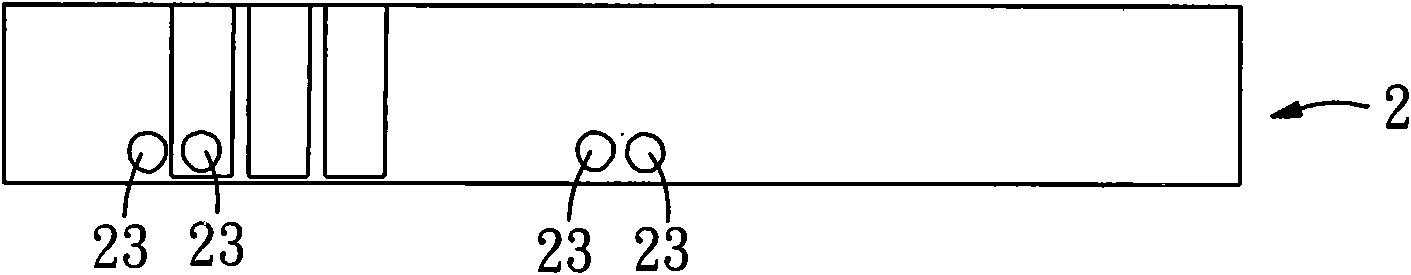

[0038] See image 3 , Figure 4 with Figure 5 , The lower surface of the battery protection board 2 is provided with a control circuit, and the battery protection board 2 is welded with a number of electronic components 20 and a pair of positive connection blocks 21 and a pair of negative connection blocks on the lower surface of the battery protection board 2 relative to the battery core 1 by SMT. 22. The pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com