Novel epoxy resin, method for producing the same, epoxy resin composition containing the epoxy resin as essential component, and cured product containing the epoxy resin as essential component

An epoxy resin, a new type of technology, applied in the field of epoxy resin, epoxy resin composition and epoxy resin cured product, can solve the problems of insufficient flexibility and reduced flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

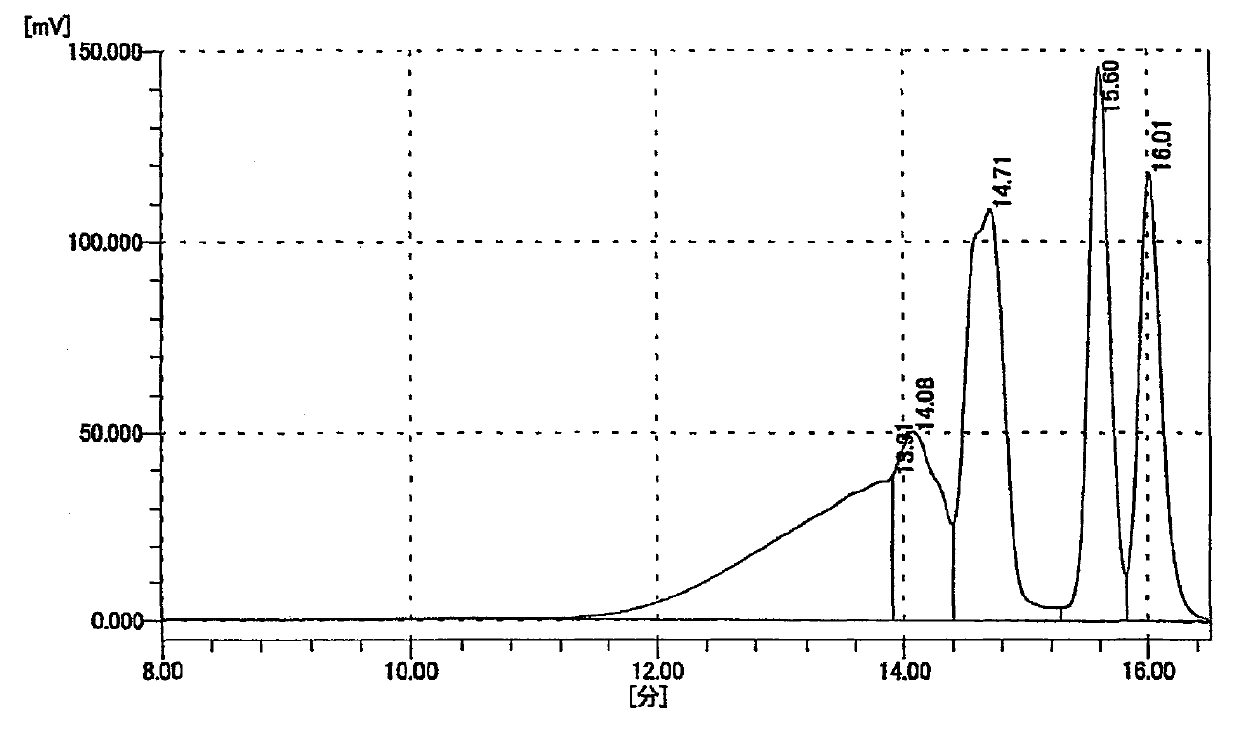

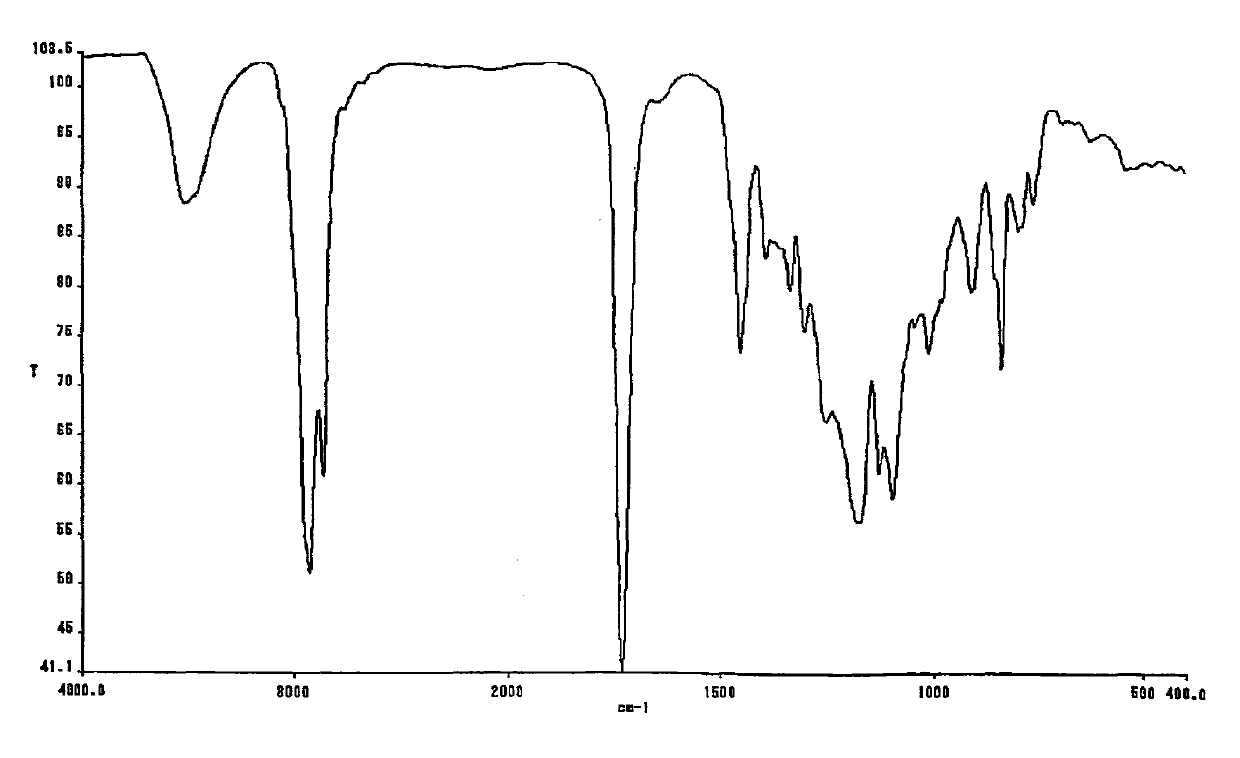

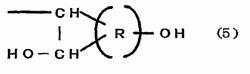

[0054] 164.5 parts of TD-EL (manufactured by 4,7-methylene-2,3-epoxy octahydro-1H-indene-ol Maruzen Petrochemical Co., Ltd.) and 160.2 parts RIKACID MH-700 (methylhexahydrophthalic anhydride, manufactured by Nippon Rika Co., Ltd.) and 17.0 parts of toluene were heated while stirring in a nitrogen atmosphere. At this time, the acid anhydride group with respect to the hydroxyl group was 0.951. The chemical formula of TD-EL is shown below.

[0055]

[0056] The reaction is carried out at 130°C until the anhydride disappears. By this reaction, a compound having one epoxy group and one carboxyl group in one molecule can be obtained. Then add CELLOXIDE 2021 (3,4-epoxycyclohexenylmethyl-3', 4'-epoxycyclohexene carboxylate) 300.8 parts, Epo Tohto ZX-1658 (cyclohexanedimethanol dishrunk Glyceryl ether) 374.4 parts, heated to make it uniform. The chemical formula of CELLOXIDE 2021 is shown below.

[0057]

[0058] As a catalyst, TPP-BB (n-butyltriphenylphosphine Bromide, ma...

Embodiment 2

[0060] TD-EL was 227.9 parts, RIKACID MH-700 was 222.2 parts, Celloxide 2021 was 200.7 parts, Epo Tohto ZX-1658 was 349.1 parts, and toluene was not used. Other than that, the same operation as in Example 1 was performed. The acid anhydride group relative to the hydroxyl group was 0.952. The epoxy equivalent of the obtained epoxy resin was 272.1 g / eq.

Embodiment 3

[0062] Put 267.1 parts of TD-EL, 232.8 parts of RIKACID MH-700, 299.9 parts of CELLOXIDE 2021, 200.2 parts of Epo Tohto ZX-1658, and 26.3 parts of toluene into the separable flask described in Example 1, stir and raise the temperature , to make it even. The reaction temperature was maintained at 90°C until the disappearance of the acid anhydride was confirmed. By this reaction, a compound having one epoxy group and one carboxyl group in one molecule can be obtained. As a catalyst, TPP-BB was dissolved in 0.1 part of acetone and added to the system. The reaction was carried out at 130° C., and the disappearance of the acid value was confirmed, which was defined as the reaction end point. The epoxy equivalent of the obtained epoxy resin was 313.9 g / eq.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com