Solar cell back surface protective film, and solar cell module provided with same

A solar cell and back protective film technology, which is applied to electrical components, circuits, photovoltaic power generation, etc., can solve the problems of insufficient adhesion and long-term durability of the filling material, and achieve excellent weather resistance, heat resistance, and durability. Excellent impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

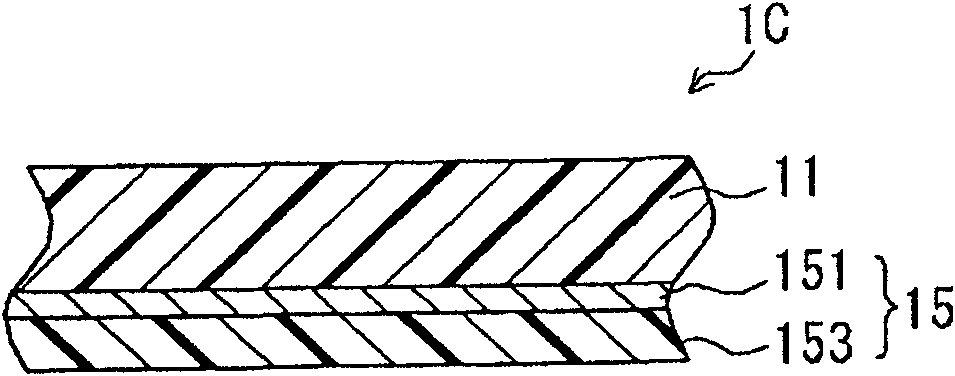

[0313] image 3 The preparation method of Membrane 1C is exemplified below.

[0314] (1) After producing a single-layer film as described above using the first thermoplastic resin composition, the single-layer film and the water vapor barrier layer having a film 151 made of metal and / or a metal oxide and a resin layer 153 15 Methods of hot-melt bonding or dry lamination of forming materials (films) or bonding with adhesives

[0315] (2) After producing a single-layer film as described above using the first thermoplastic resin composition, a film made of metal and / or metal oxide is formed on the surface of the single-layer film, and then, the film is mixed with a thermoplastic resin Other methods of hot-melt bonding or dry lamination of films made from the composition or bonding with adhesives.

[0316] In addition, when the back surface protective film for solar cells of the present invention is a film having a first resin layer, a second resin layer, a third resin layer, an...

Embodiment 1-1

[0442] 30 parts of acrylic rubber-reinforced aromatic vinyl resin, 30 parts of acrylonitrile-styrene copolymer, acrylonitrile-styrene-N-phenylmaleimide copolymer A first raw material composition consisting of 40 parts, 0.3 parts of a silane coupling agent (x), and 20 parts of a white coloring agent was kneaded at 250° C. to obtain a first thermoplastic resin composition. Then, a T-die was used to obtain a single-layer type solar cell rear surface protective film (thickness: 400 μm) composed of the first thermoplastic resin composition. Various evaluations were performed on this back surface protective film for solar cells. The results are shown in Table 1.

Embodiment 1-2~1-9 and comparative example 1-1~1-5

[0444] Except having used the component described in Table 1 in a predetermined ratio, it carried out similarly to Example 1-1, and obtained the back surface protection film for single-layer type solar cells. Table 1 shows the kneading temperature and film thickness. Various evaluations were performed on this back surface protective film for solar cells. The results are listed in Table 1 together.

[0445]

[0446] As can be seen from Table 1, the back protective films for solar cells of Comparative Examples 1-1 to 1-5 using the first thermoplastic resin composition obtained by kneading the first raw material composition not mixed with a silane coupling agent were made of ethylene - In the adhesion of a film composed of a vinyl acetate copolymer, the peel strength was as low as 10 to 15N, and the adhesion was insufficient.

[0447] On the other hand, the back surface protection films for solar cells of Examples 1-1 to 1-9 using the first thermoplastic resin composition ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com