Catalyst for selective hydrogenation of oxygen-containing olefin material, and preparation method and use thereof

A technology of selective hydrogenation and catalyst, applied in the direction of catalyst activation/preparation, selective hydrofining, metal/metal oxide/metal hydroxide catalyst, etc., which can solve the problems of poor resistance to carbon monoxide fluctuations, activity and selectivity Not high, catalyst poisoning and deactivation, etc., to achieve long regeneration cycle, reduce carbon deposition, and good anti-oxidation poisoning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

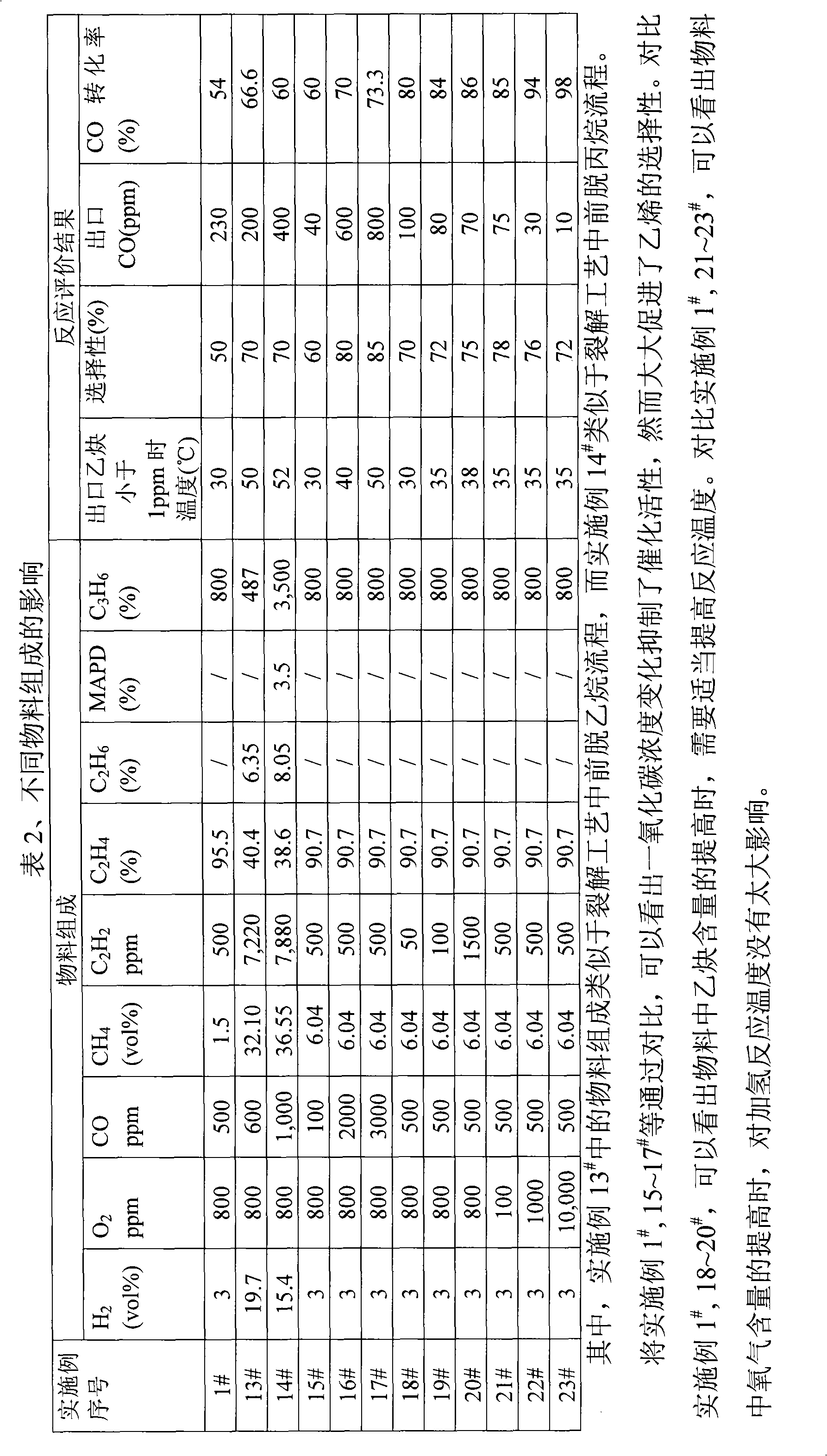

Examples

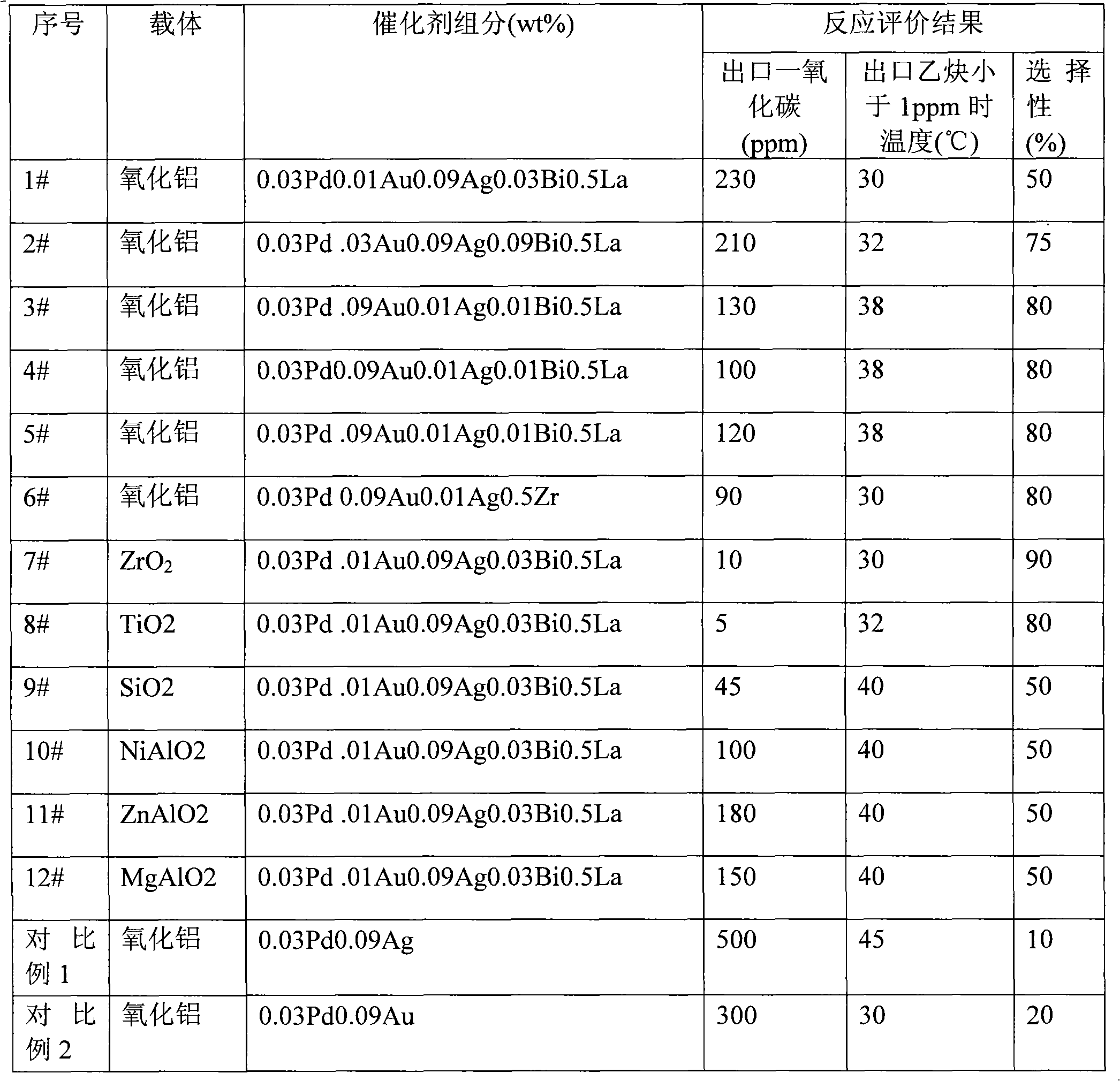

Embodiment 1

[0045] Accurately weigh 200 grams of alumina carrier and place it in a beaker. Accurately weigh lanthanum nitrate in such an amount that the final prepared catalyst contains 0.5 wt% lanthanum. Add water to dissolve it and impregnate it in equal volume, dry at 120°C for 4 hours, and then dry at 1100°C. Roast for 4 hours; get an appropriate amount of palladium nitrate solution, spray it on the above-mentioned carrier with the solution amount of equal volume impregnation, make the catalyst contain palladium 0.03wt%, then dry at 120°C for 4 hours, and bake at 500°C for 4 hours; The load is similar, and the silver of 0.09wt% and the bismuth of 0.03wt% are loaded at the same time, dry and roast as above; after that, take an appropriate amount of HAuCl 4 Gold solution, heated to 80 °C, with 0.01 M Na 2 CO 3 Solution, adjust the pH value to about 6 to prepare gold sol, load it on the above-mentioned carrier according to the principle of equal-volume impregnation, and after standing f...

Embodiment 2

[0047] The preparation method is the same as that in Example 1, after loading lanthanum, palladium, and silver on the carrier in sequence, gold is then loaded. Take an appropriate amount of gold solution, heat it to 50°C, adjust the pH value to about 10 to prepare a gold sol, load it on the above-mentioned carrier according to the principle of equal volume impregnation, and soak the above-mentioned carrier with 15% dilute ammonia water after standing for 24 hours. After repeated washing with deionized water at 50 °C to remove Cl - In this way, 0.01 wt% of gold is loaded on the carrier, and then dried at 120° C. for 4 hours and calcined at 500° C. for 4 hours. Prepared 0.03Pd 0.03Au0.09Ag0.09Bi0.5La of 1 # catalyst.

Embodiment 3

[0049] The preparation method is the same as that in Example 1, lanthanum, palladium, and gold are loaded on the carrier in sequence, and then silver is loaded. The process of loading gold is as follows. Take an appropriate amount of gold solution, heat it to 70°C, adjust the pH value to about 8 to prepare gold sol, load it on the above-mentioned carrier according to the principle of equal volume impregnation, and soak the above-mentioned carrier with 15% dilute ammonia water after standing for 24 hours. After repeated washing with deionized water at 70 °C to remove Cl - In this way, 0.01 wt% of gold is loaded on the carrier, and then dried at 120° C. for 4 hours and calcined at 500° C. for 4 hours. Prepared 0.03Pd 0.09Au0.01Ag0.01Bi0.5La of 1 # catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com