Method for immediately eliminating carbon monoxide poisoning of metal catalyst in heterogeneous catalytic hydrogenation and application

A metal catalyst, carbon monoxide technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, catalyst regeneration/reactivation, physical/chemical process catalyst, etc., can solve the deactivation of hydrogenation metal catalyst, poisoning deactivation, etc. problems, to achieve the effect of increased conversion and selectivity, improved activity and selectivity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The preparation steps of catalyst are as follows:

[0023] 1.0g iridium acetylacetonate Ir (acac) 3 Dissolved in acetylacetone to obtain 3.9264mg / mL Ir(acac) 3 The precursor solution; 0.190g of SiO 2 Carrier was added to 2.547mL Ir(acac) 3 Precursor solution, the resulting mixture was stirred and ultrasonicated for 20 minutes, transferred to a dark place for 24 hours, then placed in an oven and dried at 383K for 3 hours, and finally the obtained solid was calcined in a muffle furnace, heated to 773K at a rate of 2K / min and Keep it for 3h, and after cooling down, you can get 0.2g 5%Ir / SiO 2 catalyst.

[0024] The specific reaction steps of catalytic gas-phase selective hydrogenation of crotonaldehyde to produce crotyl alcohol are as follows: Catalyst activity evaluation is carried out on a fixed-bed device at normal pressure, and 25 mg of 5% Ir / SiO 2 The catalyst was loaded into a quartz reaction tube, and the high-purity H at 10 mL / min 2 Under the air flow, the te...

Embodiment 2

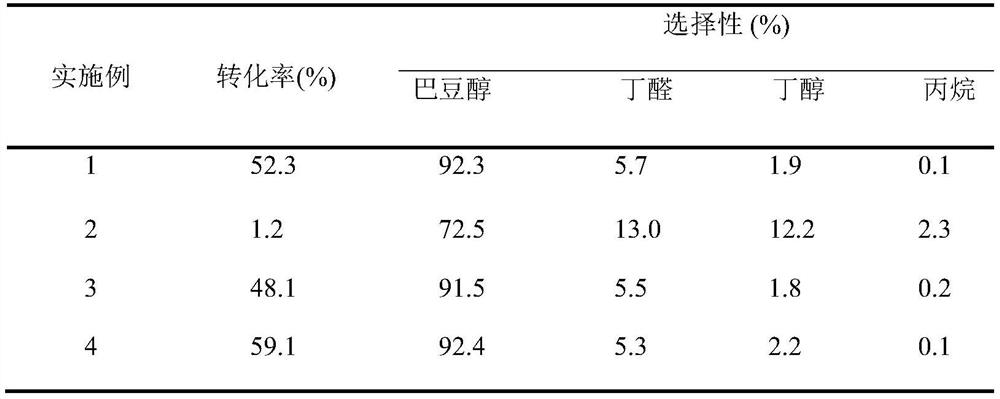

[0026] The preparation steps of the catalyst are the same as in Example 1, and the reaction conditions for the gas-phase selective hydrogenation of catalyzed crotonaldehyde to produce crotyl alcohol refer to Example 1, the difference is that high-purity H 2 into H containing traces of carbon monoxide 2 Mixed gas (concentration of carbon monoxide is 100ppm), all the other conditions are with embodiment 1. The evaluation results are shown in Table 1. When hydrogen gas similar to crude hydrogen (containing low-concentration carbon monoxide) is used as the hydrogen source, the conversion rate of crotonaldehyde is only 1.2%, and the selectivity of the product crotyl alcohol is 72.5%.

Embodiment 3

[0028] The catalyst deactivated by carbon monoxide poisoning in Example 2 is activated, and the activation gas contains O 2 and H 2 Mixed gas (O 2 The concentration of crotonaldehyde is 0.02%), the activation temperature is 423K, and the activation time is 2h; after the activation finishes, the reaction conditions of catalytic crotonaldehyde gas-phase selective hydrogenation to produce crotyl alcohol are the same as in Example 1, and the reaction results are shown in Table 1. The conversion rate of crotonaldehyde is 48.1%, the selectivity of product crotyl alcohol is 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com