Catalyst for generating hydrogen by visible light photocatalytic reduction of water, and preparation method thereof

A catalyst and water hydrogen production technology, applied in the field of solar hydrogen production, can solve the problems of economic security, national security risks, photocatalysts cannot be applied on a large scale, etc., and achieve the effect of high hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 80mg carbon nanotubes, 0.6mL 0.1mol·L -1 Aqueous copper nitrate solution was added to a 100mL beaker and diluted with water to 20mL. After stirring at room temperature for 1 h, the water was evaporated to dryness to obtain a carbon nanotube-metal salt precursor.

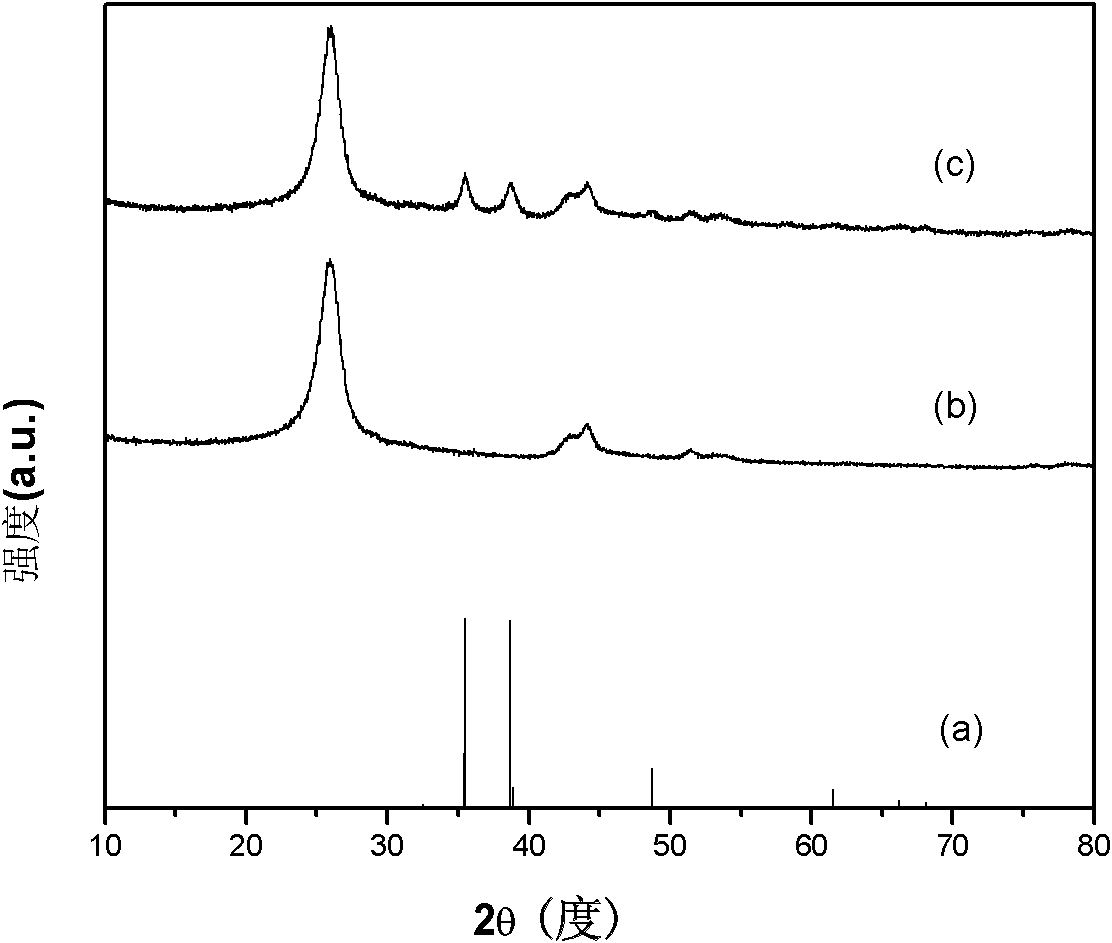

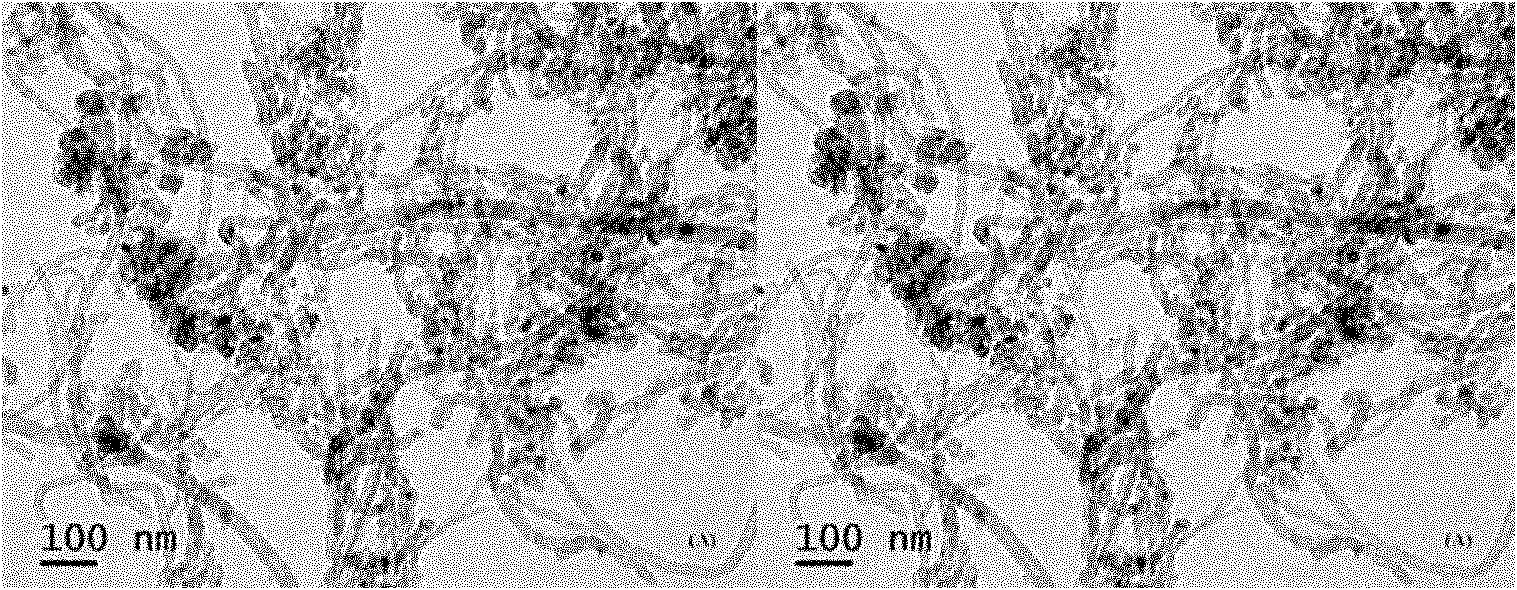

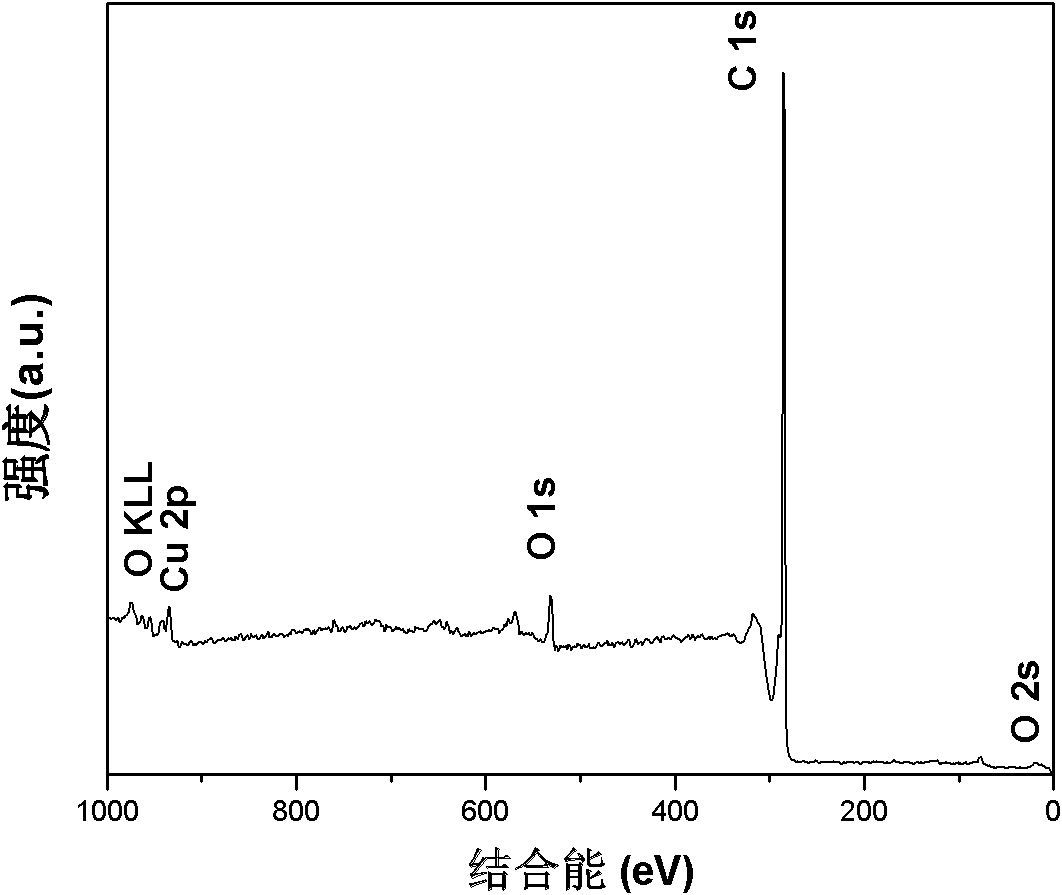

[0026] The obtained precursor was put into a muffle furnace, and calcined at 300° C. for 3 h in an air atmosphere to obtain a carbon nanotube-copper oxide system. The standard X-ray diffraction XRD spectrum of CuO is as follows figure 1 Shown in (a); The XRD pattern of multi-walled carbon nanotubes is as figure 1 Shown in (b); The XRD spectrum of carbon nanotube-copper oxide system is as figure 1 (c) shown. in addition, figure 2 A transmission electron microscope TEM photo showing a carbon nanotube-copper oxide system; image 3 The X-ray photoelectron spectroscopy XPS spectrum of the carbon nanotube-copper oxide system is shown.

[0027] Put 60mg carbon nanotube-copper oxide system into the solution of...

Embodiment 2

[0029] 85mg carbon nanotubes, 0.4mL 0.1mol·L -1 Aqueous copper nitrate solution was added to a 100mL beaker and diluted with water to 20mL. After stirring at room temperature for 1 h, the water was evaporated to dryness to obtain a carbon nanotube-metal salt precursor. (II) The obtained precursor was put into a muffle furnace, and calcined at 300° C. for 3 hours in an air atmosphere to obtain a carbon nanotube-copper oxide system. (III) Put the above-mentioned carbon nanotube-copper oxide system into the solution of 10mL eosin Y (1mg / mL), in N 2 Soak for 30 minutes under protection to obtain eosin Y, carbon nanotubes and copper oxide catalyst.

Embodiment 3

[0031] 35mg carbon nanotubes, 0.4mL 0.1mol·L -1 Aqueous copper nitrate solution was added to a 100mL beaker and diluted with water to 20mL. After stirring at room temperature for 1 h, the water was evaporated to dryness to obtain a carbon nanotube-metal salt precursor. (II) The obtained precursor was put into a muffle furnace, and calcined at 300° C. for 3 hours in an air atmosphere to obtain a carbon nanotube-copper oxide system. (III) Put the above-mentioned carbon nanotube-copper oxide system into the solution of 60mL eosin Y (1mg / mL), in N 2 Soak for 30 minutes under protection to obtain eosin Y, carbon nanotubes and copper oxide catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com