Pore-enlarged nickel oxide-calcium oxide / alumina composite catalyst, and preparation and application thereof

A composite catalyst and alumina technology, applied in the fields of chemical industry and energy, can solve problems such as the inability to meet the needs of industrialization of ReSER hydrogen production, and achieve the effects of good hydrogen production activity and stability, high reaction efficiency, and simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] ①Weigh 40g of polyethylene glycol (average molecular weight is 6000), dissolve it in water at 50°C to disperse it evenly, and prepare a pore-enlarging agent slurry;

[0039] ②The pore expander slurry in ①, 250g of aluminum sol with a solid content of 5%, the water dispersion prepared with 50g of nano-calcium carbonate with a particle size of 30nm, and the mass percentage concentration prepared with 46.04g of nickel nitrate hexahydrate 10% nickel nitrate aqueous solution mixed and stirred evenly.

[0040] ③The mixture obtained in step ② was dried at 80°C for 6h, then calcined at 600°C for 4h, and finally crushed and sieved to obtain a composite catalyst, which was designated as Cata-1.

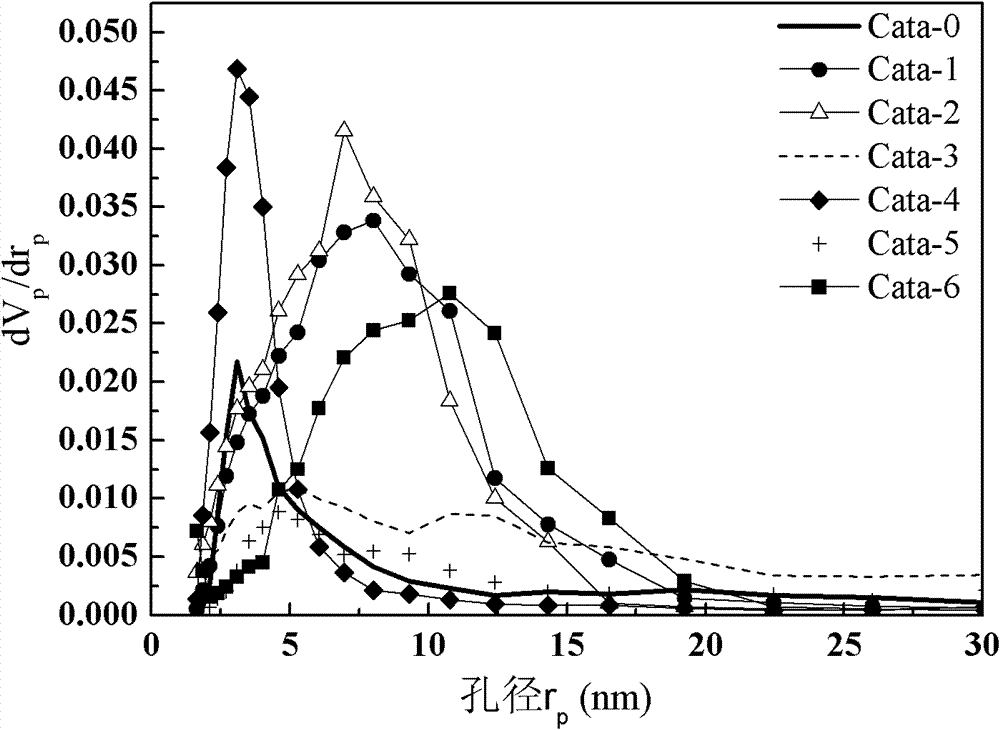

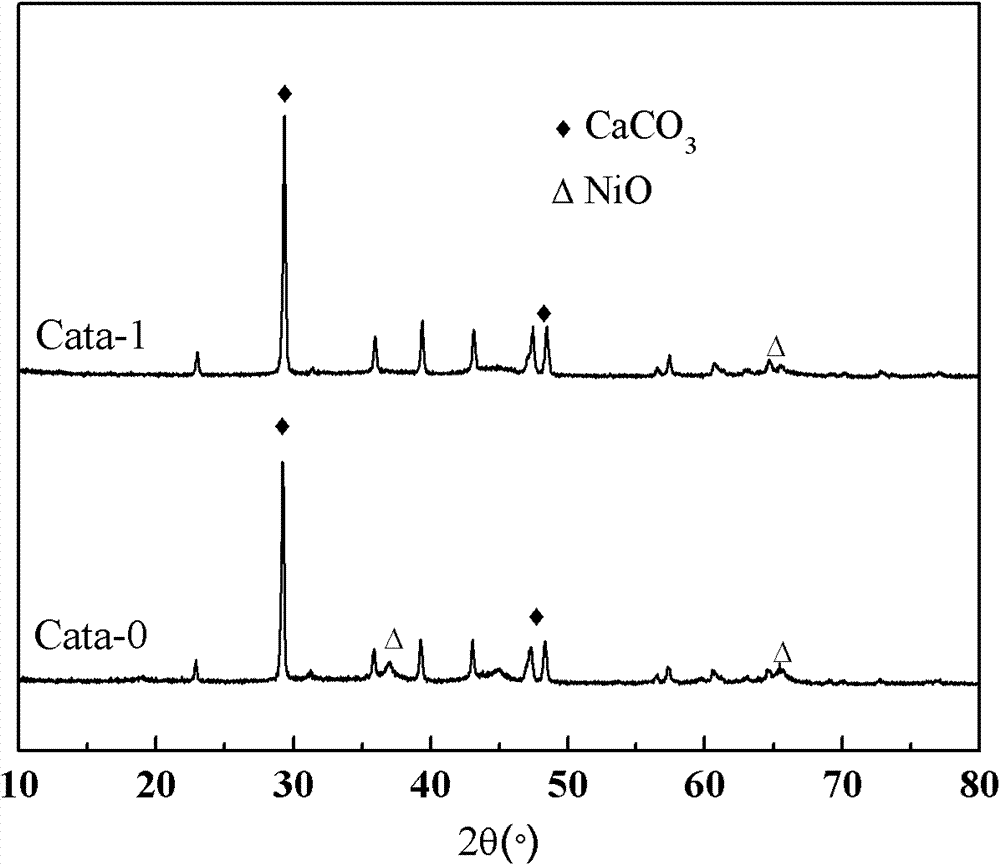

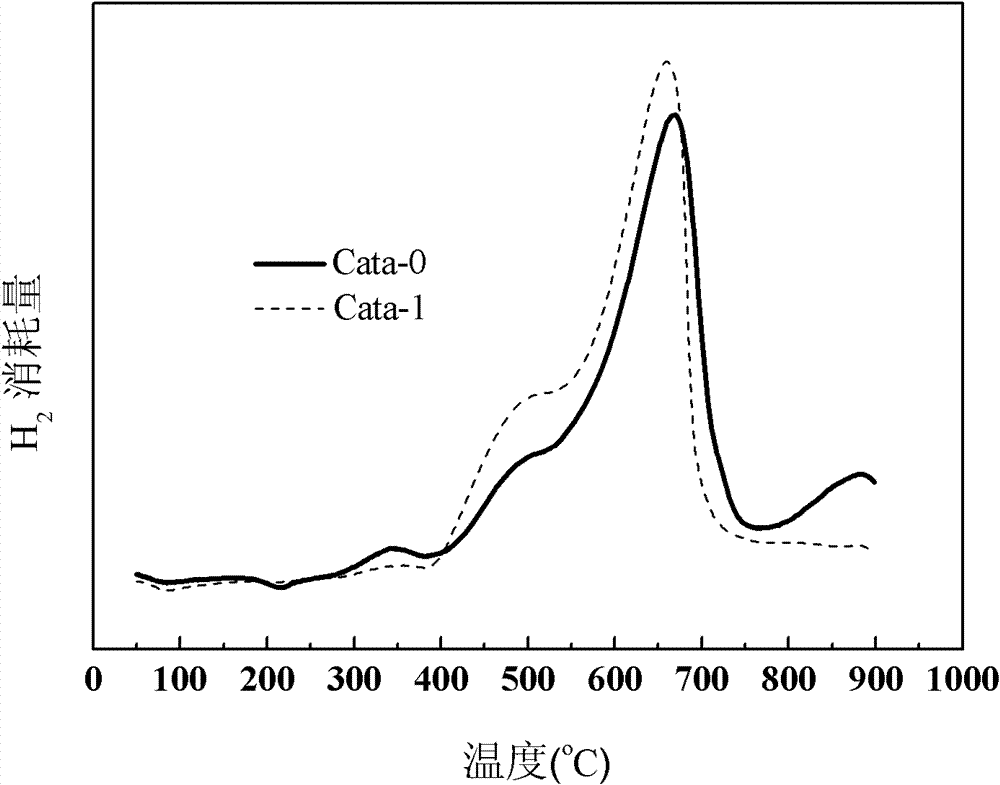

[0041] After characterization, the composite catalyst prepared above is a pore-expanding modified nickel oxide-calcium oxide / alumina composite catalyst, and its composition includes: CaO formed by thermal decomposition with nano-calcium carbonate as the precursor, and aluminum sol as the...

Embodiment 2

[0043] ①Weigh 20g of polyethylene glycol (average molecular weight is 2000), dissolve it in water at 0°C to disperse it evenly, and prepare the pore expander slurry;

[0044] ②Combine the pore expander slurry in ① with 180g of aluminum sol with a solid content of 10%, the aqueous dispersion prepared with 55g of nano-calcium carbonate with a particle size of 70nm, and the mass percentage concentration prepared with 19.64g of nickel nitrate hexahydrate 5% nickel nitrate aqueous solution mixed and stirred evenly.

[0045] ③The mixture obtained in step ② was dried at 80°C for 6h, then calcined at 600°C for 4h, and finally crushed and sieved to obtain a composite catalyst, which was designated as Cata-2.

[0046] After characterization, the composite catalyst prepared above is a pore-expanding modified nickel oxide-calcium oxide / alumina composite catalyst, and its composition includes: CaO formed by thermal decomposition with nano-calcium carbonate as the precursor, and aluminum so...

Embodiment 3

[0048] ① Weigh 45g of ammonium aluminum carbonate, disperse evenly in water at 80°C, and prepare pore expander slurry;

[0049] ② Mix the pore expander slurry in ① with 300g of aluminum sol with a solid content of 20%, the aqueous dispersion prepared with 50g of nano-calcium carbonate with a particle size of 100nm, and the mass percentage concentration prepared with 39.64g of nickel nitrate hexahydrate. 20% aqueous solution of nickel nitrate was mixed and stirred evenly.

[0050] ③The mixture obtained in step ② was dried at 80°C for 6h, then calcined at 600°C for 4h, and finally crushed and sieved to obtain a composite catalyst, which was designated as Cata-3.

[0051] After characterization, the composite catalyst prepared above is a pore-expanding modified nickel oxide-calcium oxide / alumina composite catalyst, and its composition includes: CaO formed by thermal decomposition with nano-calcium carbonate as the precursor, and aluminum sol as the aluminum source Al 2 o 3 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com