Efficient photocatalytic hydrogen production catalytic system and preparation method thereof

A catalytic system and photocatalytic technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., to achieve the effects of good stability, easy preparation, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

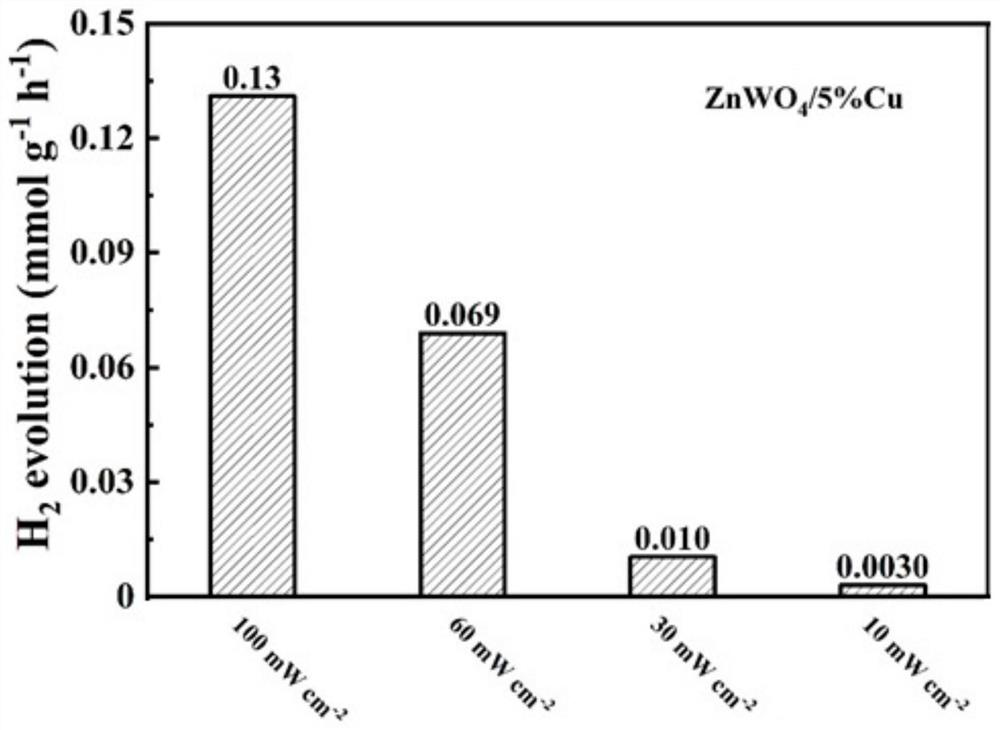

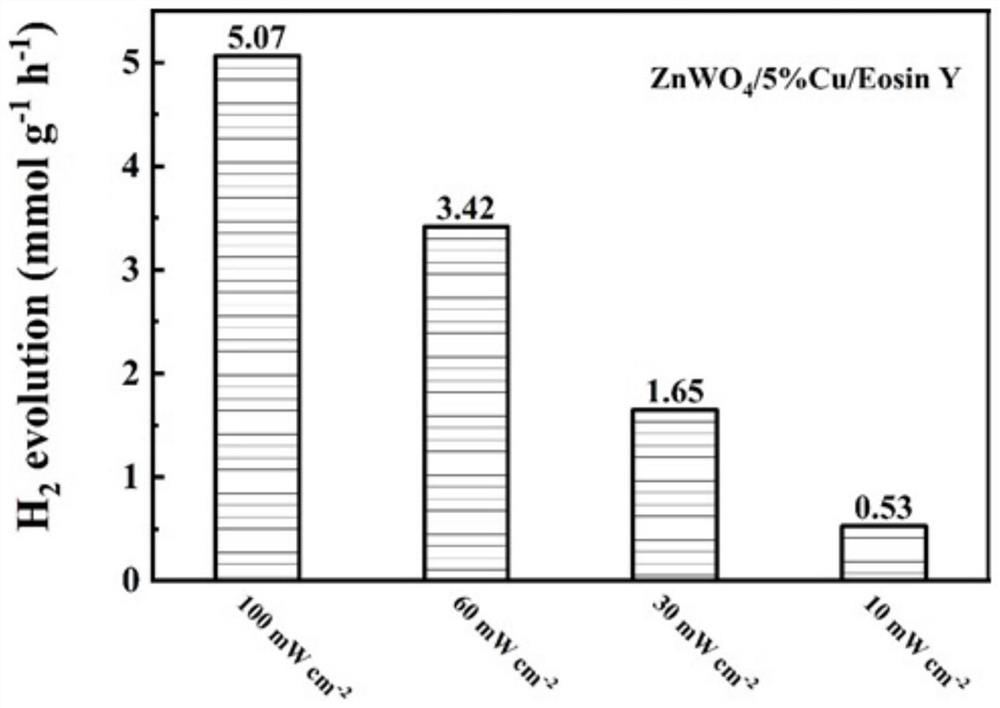

Problems solved by technology

Method used

Image

Examples

preparation example Construction

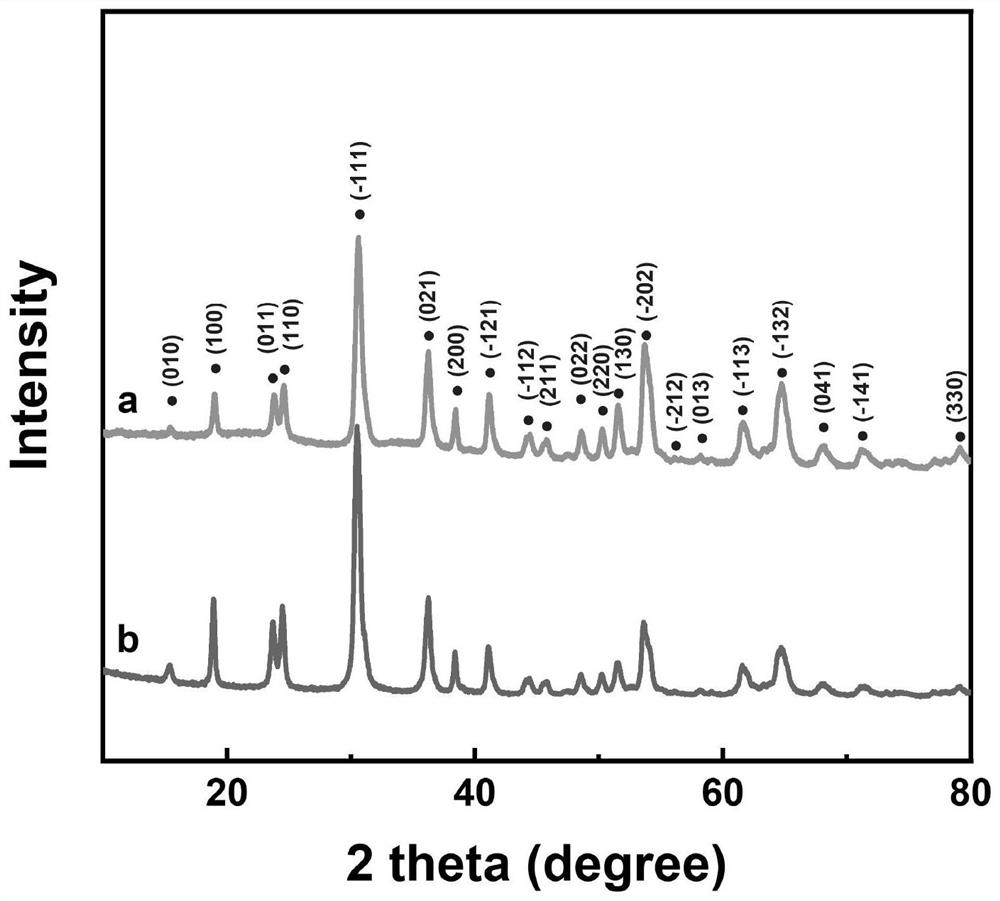

[0033] A preparation method of the above-mentioned high-efficiency photocatalytic hydrogen production catalytic system, the preparation method specifically includes the following steps:

[0034] (1) Take zinc salt, water and cetyltrimethylammonium bromide to make solution A, take tungsten salt and water to make solution B, then add solution B dropwise to solution A and stir for 1.5 to 2.5 hours to obtain mixture, and then transfer the resulting mixture to a hydrothermal kettle, heat it to 160-200°C in an airtight manner, and keep it warm for 18-22 hours. After the reaction is completed, ZnWO is obtained by post-processing 4 The post-treatment of nanosheets is as follows: centrifuge and filter the reaction system after the hydrothermal reaction, then wash the collected precipitate with water, and then dry it at 60-100°C for 22-26 hours, wherein the zinc salt is Zinc nitrate hexahydrate, tungsten salt is sodium tungstate; in solution A, the concentration of zinc salt is 0.1~0.6m...

Embodiment 1

[0039] A high-efficiency photocatalytic hydrogen production catalytic system comprising Eosin Y photosensitizer dye as a photosensitizer, CuO nanoparticles as a cocatalyst, and ZnWO as a main catalyst 4 Nanosheets, Eosin Y photosensitizer dye and CuO nanoparticles were all loaded on ZnWO 4 on the nanosheet. The catalytic system is prepared by the following steps:

[0040] (1) Weigh 0.59g of zinc nitrate hexahydrate and transfer it to a beaker, then add 20mL of deionized water, stir and dissolve to obtain a concentration of 0.1mol L -1 solution of zinc nitrate.

[0041] (2) After slowly adding 0.072g of cetyltrimethylammonium bromide to the above-mentioned zinc nitrate solution, stir fully until the cetyltrimethylammonium bromide is completely dissolved, and this solution is recorded as A solution (A solution In, the concentration of zinc nitrate is 0.1molL -1 , the concentration of cetyltrimethylammonium bromide is 0.01mol L -1 ).

[0042] (3) Weigh 0.66g of sodium tungs...

Embodiment 2

[0051] A high-efficiency photocatalytic hydrogen production catalytic system comprising Eosin Y photosensitizer dye as a photosensitizer, CuO nanoparticles as a cocatalyst, and ZnWO as a main catalyst 4 Nanosheets, Eosin Y photosensitizer dye and CuO nanoparticles were all loaded on ZnWO 4 on the nanosheet. The catalytic system is prepared by the following steps:

[0052] (1) Weigh 3.57g of zinc nitrate hexahydrate and transfer it to a beaker, then add 20mL of deionized water, stir and dissolve to obtain a concentration of 0.6mol L -1 solution of zinc nitrate.

[0053] (2) After slowly adding 0.728g of cetyltrimethylammonium bromide to the above-mentioned zinc nitrate, stir fully until the cetyltrimethylammonium bromide is completely dissolved, and this solution is recorded as A solution (in A solution , the concentration of zinc nitrate is 0.6mol L -1 , the concentration of cetyltrimethylammonium bromide is 0.1molL -1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com