Metallocene catalyst-loaded hexagonal mesoporous material and preparation method thereof

A metallocene catalyst, mesoporous material technology, applied in the direction of catalyst carrier, chemical instrument and method, physical/chemical process catalyst, etc., can solve the problem of low ethylene polymerization activity, poor thermal stability and hydrothermal stability, pore wall collapse, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Hexagonal Mesoporous Materials Supporting Cocatalyst Methylaluminoxane (MAO) and Procatalyst Bis(1-Methyl-3-butyl-cyclopentadienyl)Zirconium Dichloride

[0032] (1) 2.0 grams of F108 (Fuka company trade name Substance F108) with 5.24 g K 2 SO 4 Add to 60 grams of 2N (2N) hydrochloric acid solution, stir at 38°C until F108 is completely dissolved;

[0033] (2) Add 4.2 grams of ethyl orthosilicate to the above solution, stir at 38°C for 15 minutes, and stand at 38°C for 24 hours;

[0034] (3) Obtain the original powder mesoporous material after adding 100 grams of deionized water for dilution, filtering, washing and drying;

[0035] (4) Calcining the original powder mesoporous material at 400°C for 10 hours to remove the template agent to obtain the hexagonal mesoporous material;

[0036] (5) Calcining the hexagonal mesoporous material at 400°C for 10 hours under the protection of nitrogen (thermal activation), removing the hydroxyl group and residual ...

Embodiment 2

[0040] Application method of hexagonal mesoporous material supporting cocatalyst methylaluminoxane (MAO) and main catalyst bis(1-methyl-3-butyl-cyclopentadienyl) zirconium dichloride in polyolefin.

[0041] Homopolymerization of ethylene

[0042] In a 2-liter stainless steel autoclave, replace three times with nitrogen and ethylene respectively, then add 200 milliliters of hexane solvent, raise the temperature of the kettle to 80 ° C, then add the remaining 800 milliliters of hexane solvent, with the addition of hexane, Add 2 ml of 1 mol / L triethylaluminum (TEA) hexane solution, then add 157.6 mg of FDU6-MB, raise and maintain the pressure to 1.0 MPa, and react at 80°C for 1 hour. After the end of the polymerization reaction, the polyethylene particle powder was collected and weighed to obtain 311 grams. The efficiency of the catalyst was 1973g PE / gcat h (1.7 × 10 8 gPE / (mol Zr h)), bulk density (BD) is 0.34g / ml, melt index: MI 2.16 =0.017g / 10min.

Embodiment 3

[0044] Ethylene copolymerization

[0045] In a 2-liter stainless steel autoclave, replace three times with nitrogen and ethylene respectively, then add 200 milliliters of hexane solvent, raise the temperature of the kettle to 80 ° C, then add the remaining 800 milliliters of hexane solvent, with the addition of hexane, Add 2 ml of 1 mol / L triethylaluminum (TEA) hexane solution and 10 ml of hexene, then add 34.6 mg of FDU6-MB1, raise and maintain the pressure to 1.0 MPa, and react at 80°C for 1 hour. After the end of the polymerization reaction, the polyethylene particle powder was collected and weighed to obtain 320 grams. The efficiency of the catalyst was 2377gPE / gcat h (2.4×10 8 gPE / (mol Zr h)), bulk density (BD) is 0.3g / ml, melt index: MI 2.16 = 0.048 g / 10 min.

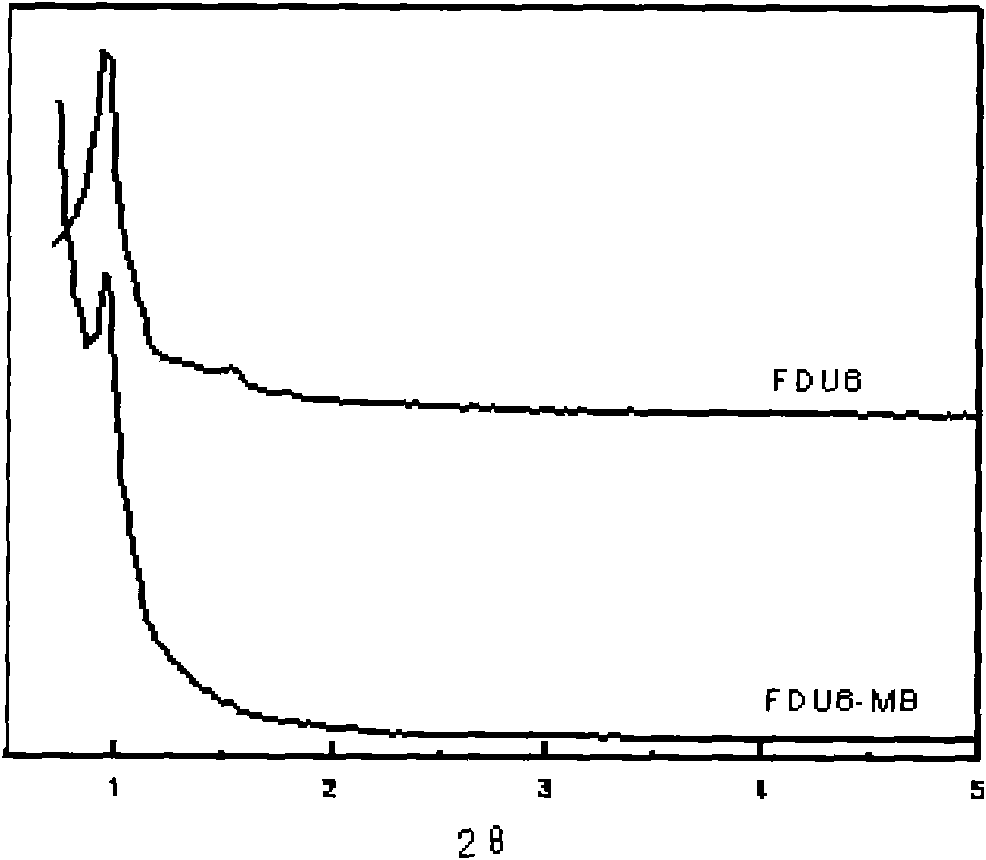

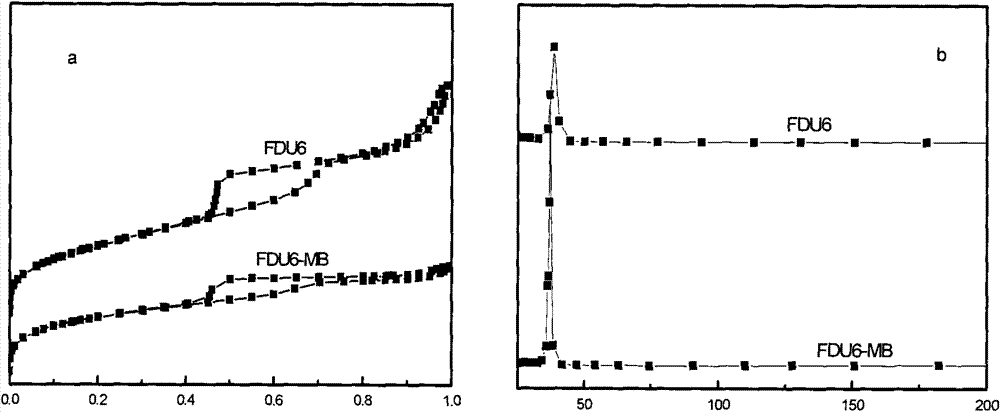

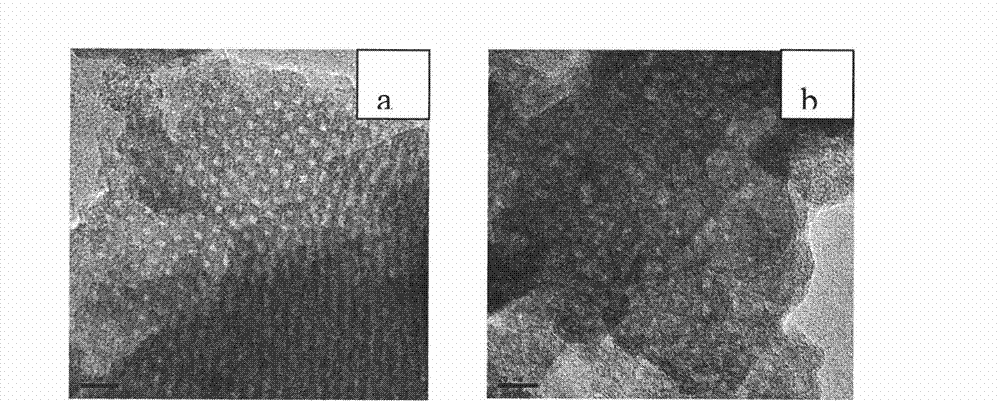

[0046] figure 1 It is the XRD structure comparison diagram of the hexagonal mesoporous material FDU6 and FDU6-MB (the abscissa is 2θ, and the unit is 0 ). Figure (1)a is the XRD spectrum of the hexagonal meso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com