Method for treating high ammonia nitrogen wastewater by two-stage A/O process

A high ammonia nitrogen, process technology, applied in aerobic and anaerobic process treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve high operating costs, reduce internal return flow, and many structures and other problems, to achieve the effect of saving operating costs, reducing operating costs, and fewer structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The water quality of this process is:

[0040] PH: 6~9 CODcr: 100-500mg / L NH 3 -N: 100-300mg / L

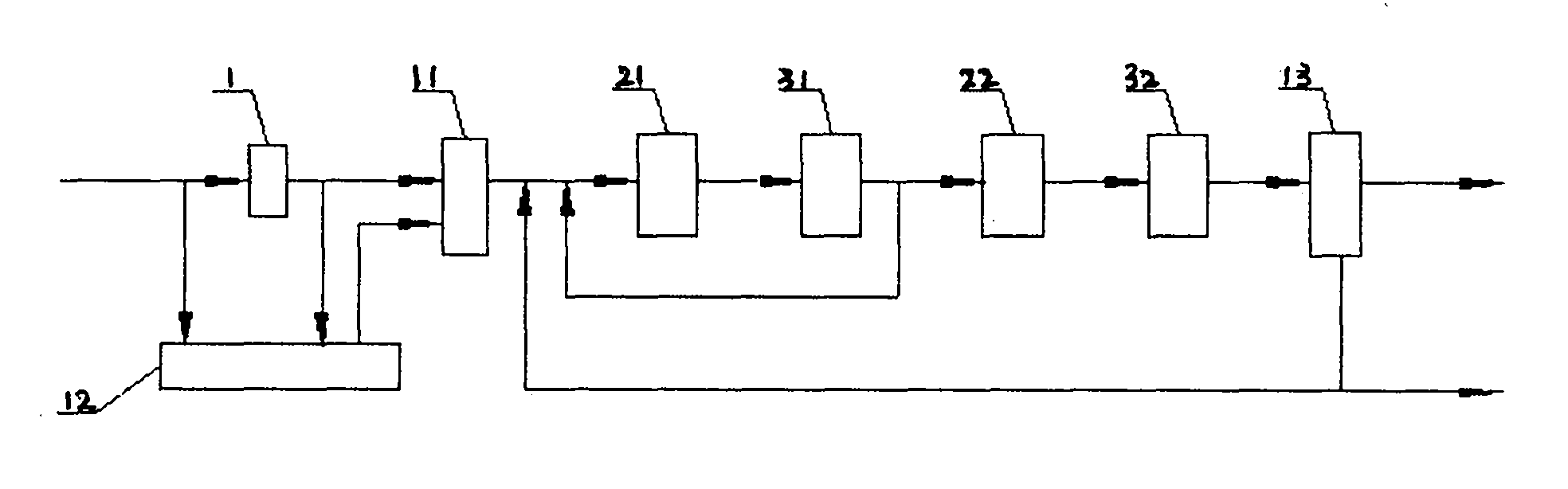

[0041] The sewage from the plant area first passes through the grille 1 to remove the larger floating matter, and then enters the homogenization tank 11; in the homogenization tank 11, it is mechanically uniformly stirred to prevent the deposition of suspended matter. If the sewage volume is too large, the sewage enters the homogenization tank. The overflow in front of the pool enters the accident adjustment tank 12, if the sewage water quality suddenly changes greatly, the sewage going to the homogenization tank after passing through the grid 1 is directly switched to the accident adjustment tank 12, and then evenly raised to homogeneity by the small flow pump Pool 11: The sewage flows into the first stage anoxic tank (A1 tank) 21 after being evenly stirred by the homogenization tank 11. The methanol residue is added to 21 and stirred evenly. The control period is 8h, and the DO...

Embodiment 2

[0044] The water quality of this process is:

[0045] PH: 6~9 CODcr: 100-500mg / L NH 3 -N: 100-300mg / L

[0046] The sewage from the plant area first passes through the grille 1 to remove the larger floating matter, and then enters the homogenization tank 11; in the homogenization tank 11, it is mechanically uniformly stirred to prevent the deposition of suspended matter. If the sewage volume is too large, the sewage enters the homogenization tank. The overflow in front of the pool enters the accident adjustment tank 12, if the sewage water quality suddenly changes greatly, the sewage going to the homogenization tank after passing through the grid 1 is directly switched to the accident adjustment tank 12, and then evenly raised to homogeneity by the small flow pump Tank 11: The sewage flows into the first stage anoxic tank (A1 tank) 21 after being evenly stirred by the homogenization tank 11. The methanol residue is added to 21 and stirred evenly. The control period is 13h, and the D...

Embodiment 3

[0049] The water quality of this process is:

[0050] PH: 6~9 CODcr: 100-500mg / L NH 3 -N: 100-300mg / L

[0051] The sewage from the plant area first passes through the grille 1 to remove the larger floating matter, and then enters the homogenization tank 11; in the homogenization tank 11, it is mechanically uniformly stirred to prevent the deposition of suspended matter. If the sewage volume is too large, the sewage enters the homogenization tank. The overflow in front of the pool enters the accident adjustment tank 12, if the sewage water quality suddenly changes greatly, the sewage going to the homogenization tank after passing through the grid 1 is directly switched to the accident adjustment tank 12, and then evenly raised to homogeneity by the small flow pump Pool 11: The sewage flows into the first stage anoxic tank (A1 tank) 21 after being uniformly stirred by the homogenization tank 11. Add methanol residue in 21 and stir evenly. The control cycle is 16h, and the DO is 0.2mg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com