Process for manufacturing organic fertilizer from organic wastes

A technology of organic waste and organic fertilizer, applied in the direction of organic fertilizer, etc., can solve the problems of a large amount of smoke and waste residue, landfill occupying a large area, secondary pollution of groundwater, etc., and achieve the goal of blocking transmission, saving money, and protecting the rural environment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

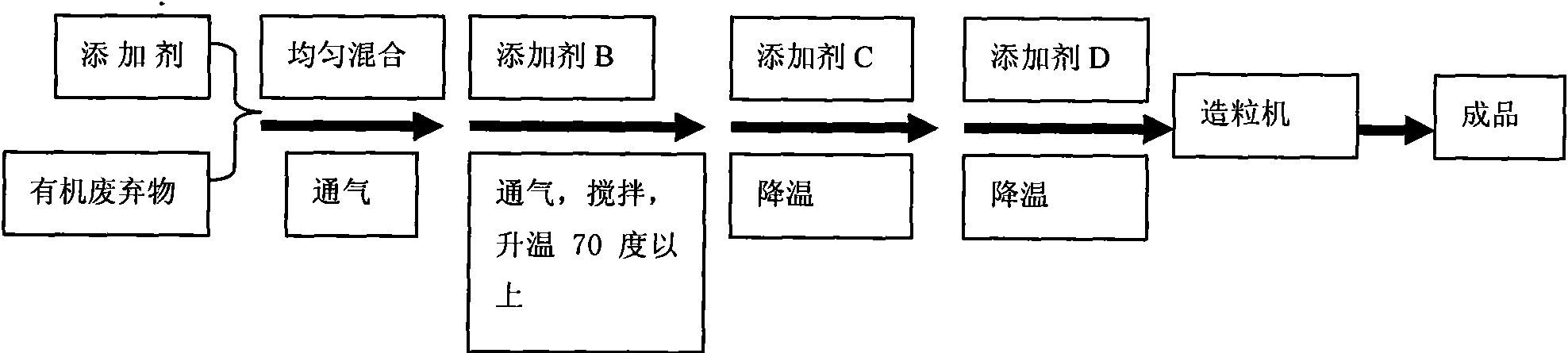

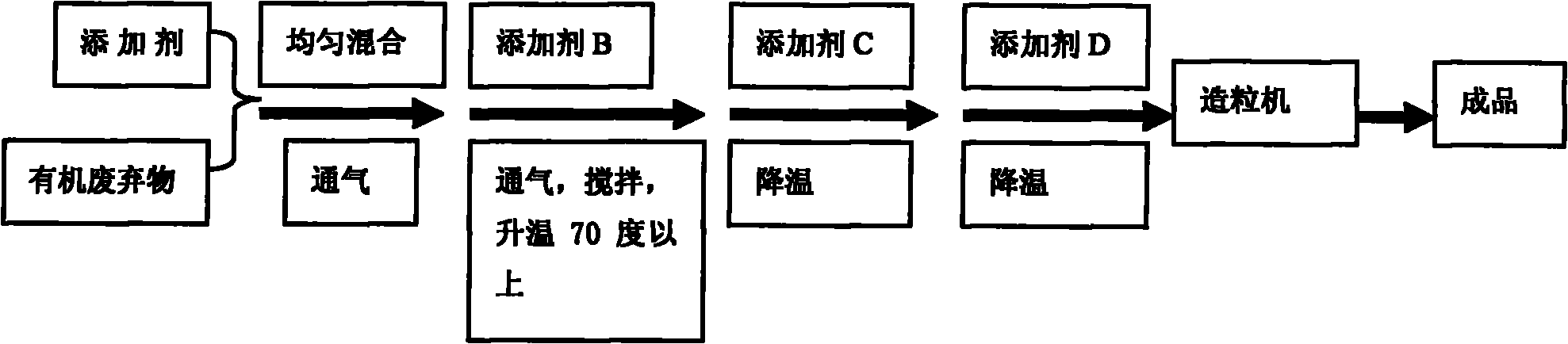

[0027] like figure 1 Shown, in a kind of embodiment of the technology that utilizes organic waste to manufacture organic fertilizer of the present invention, described technology is raw material with the excrement of city sludge and livestock, poultry, comprises the following steps:

[0028] a. Mix the organic waste containing urban sludge and livestock and poultry manure with the dry matter of various plant roots and aboveground parts, so that the carbon-nitrogen ratio of the mixed material is 15-45, and the moisture content is 45-75%;

[0029] b. Pile the materials described in step a on the ground where air enters the system, and place them for 5-8 days to decompose polysaccharides into monosaccharides.

[0030] c. Add additive B with a weight of 0.1 to 0.5% of the material to the material described in step a, stir evenly, mix and stack, and decompose cellulose and other substances; the additive B includes indigenous bacteria, filamentous bacteria, bacteria, The organic fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com