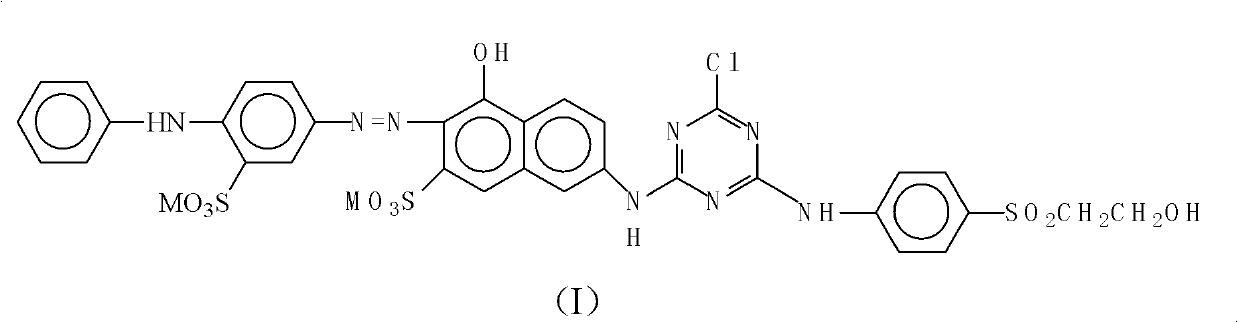

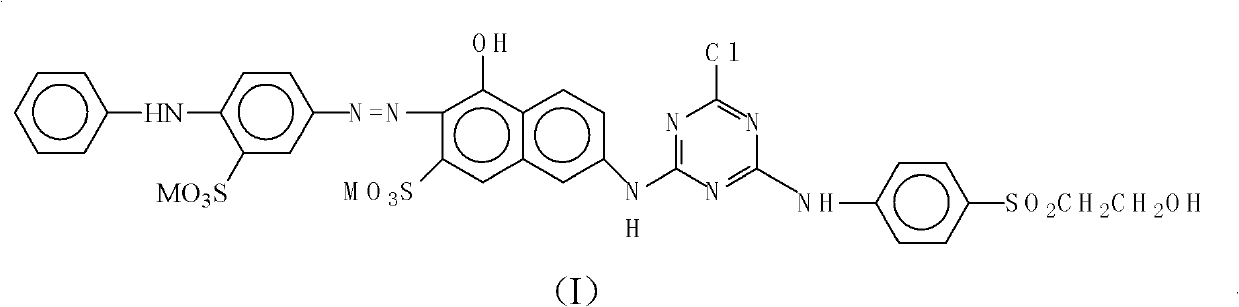

Dye suitable for nylon dyeing

A nylon and dye technology, used in azo dyes, organic dyes, reactive dyes, etc., can solve the problem of not meeting the needs of nylon dyeing, and achieve the effects of bright color, convenient use and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation of the nylon reactive red dye compound of embodiment 1 structural formula (II)

[0063]

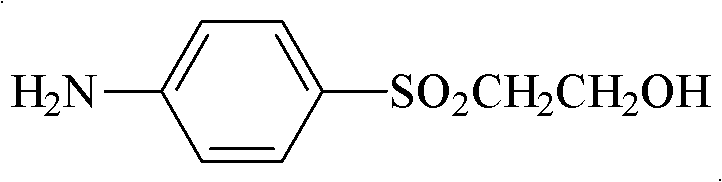

[0064] a, the preparation of condensate:

[0065] In the dissolution tank, add a small amount of bottom water and 30Kg of p-β-hydroxyethyl sulfone aniline, and use NaHCO 3 Neutralize pH=4-5 to obtain p-β-hydroxyethyl sulfone aniline solution; add a small amount of water and a small amount of crushed ice to the reaction kettle, then add 19Kg of cyanuric chloride, and add p-β dropwise while stirring -Hydroxyethyl sulfone aniline, T=10-15°C, pH=2-3.5, after the dropwise addition, react for 5 hours to obtain a primary condensation liquid; add 26.5Kg of J acid to the primary condensation liquid to adjust T=35- 40°C, pH=5-6, react for 3 hours to obtain secondary condensation liquid.

[0066] b, 4-aminodiphenylamine-2-sulfonic acid diazotization:

[0067] Add bottom water and 20Kg of 4-aminodiphenylamine-2-sulfonic acid to the reaction kettle, stir evenly, add crushe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com