Hydrocracking method of deep cut anthracene oil

A technology of hydrocracking and deep anthracene oil, which is applied in the fields of hydrotreating process, petroleum industry, and hydrocarbon oil treatment, etc. It can solve the problem that the nitrogen content of heavy distillate meets the feed requirements, the activity stability of hydrogenation catalyst is unfavorable, Affecting the operation cycle of the device and other issues, achieving the effect of safe and stable operation, saving equipment investment and increasing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

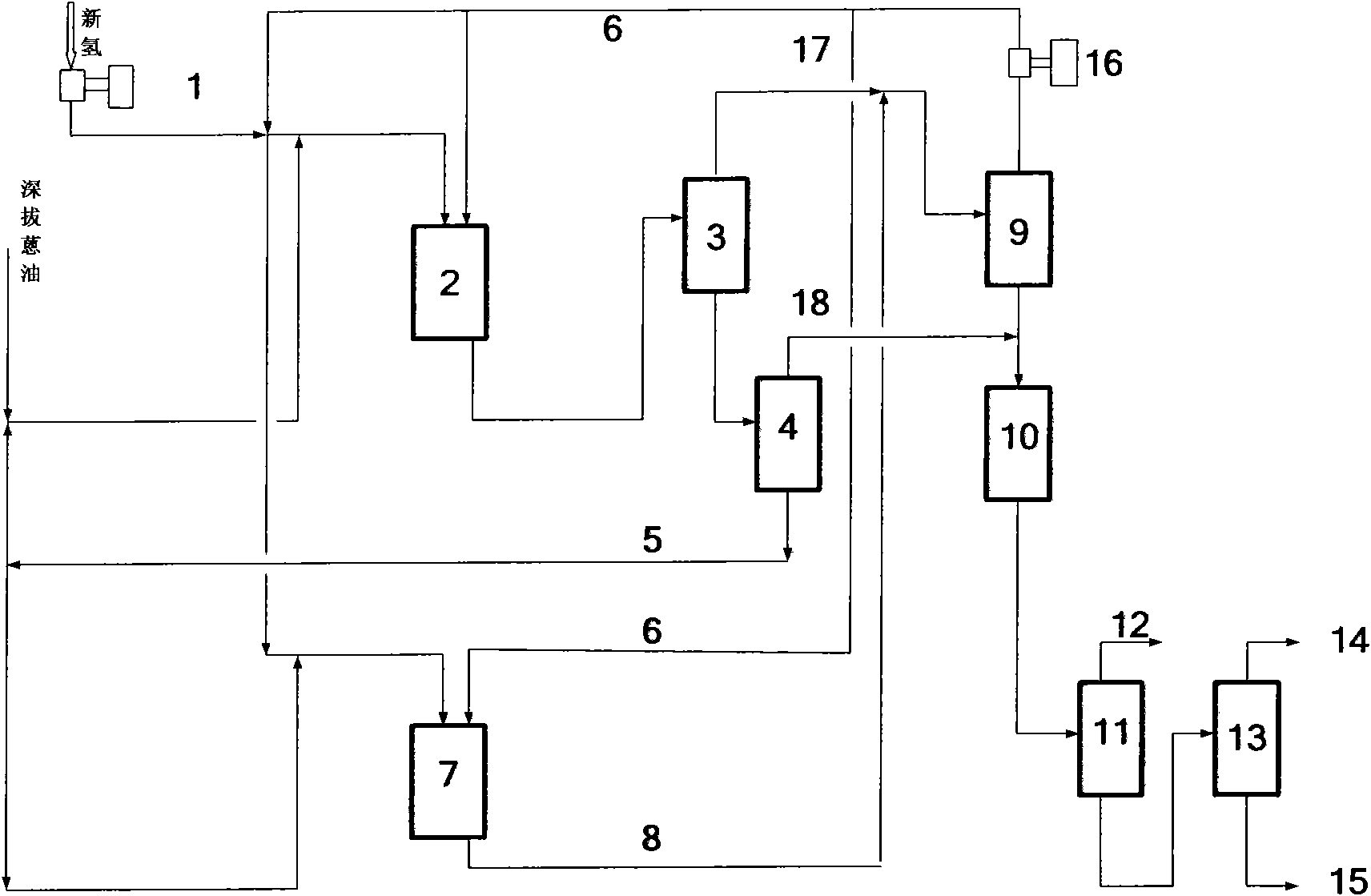

[0060] See Table 2 for the properties of deep drawn anthracene oil raw materials. See the example process figure 1 .

[0061] Table 2 Feedstock oil properties

[0062] Crude oil name

Deep drawn anthracene oil

Distillation range / ℃

IBP / 10%

203 / 324

30% / 50%

345 / 380

70% / 90%

407 / 492

95% / EBP

550 / 648

Density (20℃) / g·cm -3

1.15

S / μg·g -1

5500

N / μg·g -1

13200

Four components*,% (mass fraction)

Saturation point

0.1

Aromatic

72.09

Gum

23.31

4.5

[0063] *The four components are measured using SH / T 0509-1992 standard method.

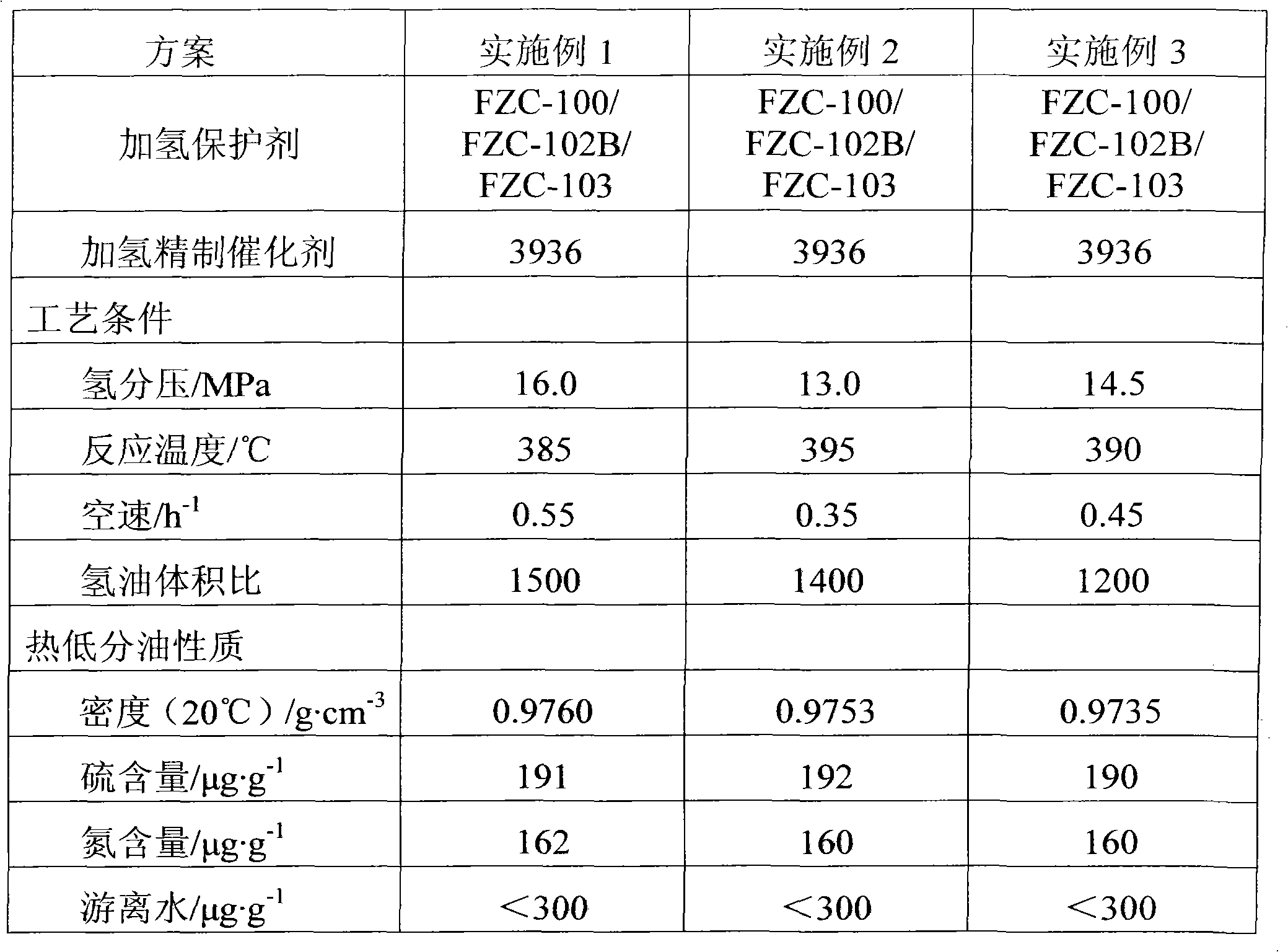

[0064] In the embodiment, two reactors are used in the hydrorefining reaction zone. The first reactor is filled with hydrogenation protective agents FZC-100, FZC-102B, and FZC-103 from top to bottom, and the second reactor is filled with hydrorefining catalyst. 3936. In the embodiment, the volume ratio of FZC-100:FZC-102B:FZC-103:3936 is as follows: 6:15:19:60. The results of the reaction are shown in Table 3.

Embodiment 4

[0066] The hot low-fraction oil obtained in Example 1 is recycled back to the hydrorefining reaction zone at a circulating weight ratio of 3.0, and the remaining part enters the hydrocracking reaction zone, and passes through the hydrorefining catalyst 3936, the hydrodecarbonization catalyst HDC-1, The volume ratio of the hydrocracking catalyst A1 and the post-treatment hydrofining catalyst FF-26 is 40:15:40:5.

Embodiment 5

[0068] The hydrorefining oil obtained in Example 1 was replaced with the hydrorefining oil obtained in Example 2, the cycle weight ratio was 5.0, the hydrocracking catalyst was changed to A2, and the rest were the same as in Example 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com